A kind of pipeline heat insulation protective cover and its installation method

A protective cover and pipeline technology, which is applied in the direction of pipeline protection, pipeline damage/abrasion prevention, pipes/pipe joints/pipe fittings, etc. It can solve the problems of inconvenient pipeline production and secondary processing, and achieve convenient installation, not easy to fall, and firm installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

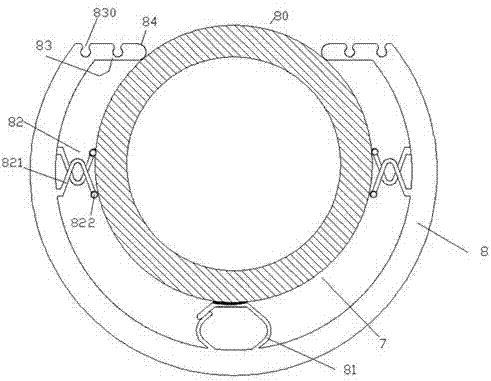

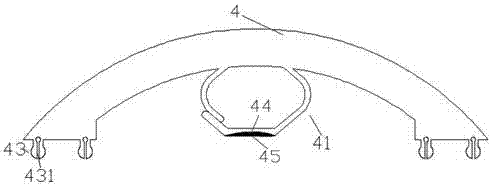

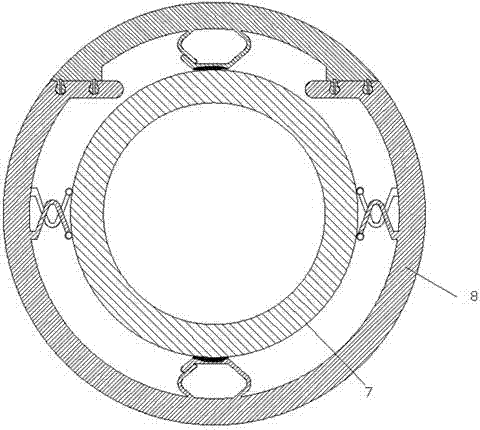

[0012] Combine below Figure 1-4 The present invention will be described in detail.

[0013] According to the embodiment of the pipeline heat insulation protective cover, it is used to be sleeved on the outside of the pipeline 7 to play the role of heat insulation protection, and includes the main protection part 8 as a larger circular section column that can be combined to form a cylinder and the smaller one as a cylinder. The cover body part 4 of the circular section cylinder, wherein, the bottom of the main protection part 8 and the top of the cover part 4 are symmetrically provided with elastic countertop platform pipe fittings 81, 41, and the main protection part 8 The opposite sides in the diametrical direction are symmetrically provided with elastic clip assemblies 82, so that the two elastic countertop platform pipes 81, 41 can form a vertical clamp for the pipeline 7, and the diametrically opposite The two elastic clip assemblies 82 can clamp the pipe 7 in the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com