Pipeline protective cover device high in protection performance and installation method thereof

A protective and protective cover technology, which is applied in the field of pipeline protective cover devices, can solve the problems of inconvenient secondary processing of pipeline production, and achieve the effect of convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

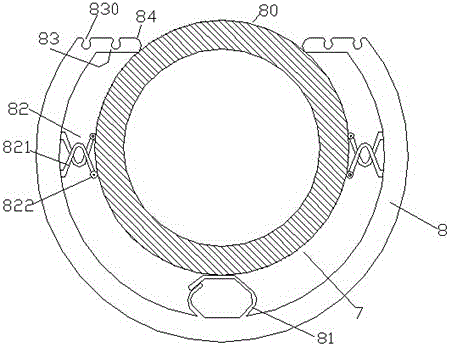

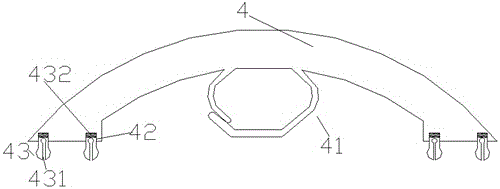

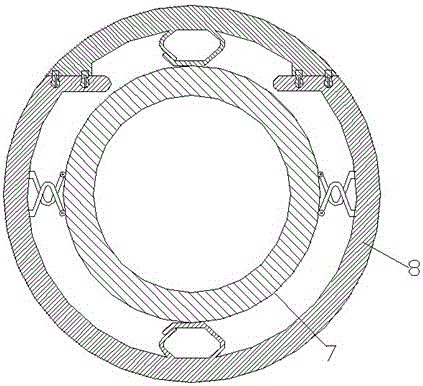

[0012] Combine below Figure 1-4 The present invention will be described in detail.

[0013] According to the strong protective pipe protective cover device of the embodiment, it is used to be sleeved on the outside of the pipe 7 to play a role of heat insulation protection, and includes the main protective part 8 and the The cover body 4 which is a cylinder with a smaller circular section, wherein, the bottom of the main protective part 8 is symmetrically arranged with the top of the cover body 4 with elastic counter-top platform pipes 81, 41, and the main protection part 8 Elastic clip assemblies 82 are arranged symmetrically on opposite sides of the protective part 8 in the diameter direction, so that the two elastic countertop platform pipes 81, 41 can form a vertical clamp for the pipeline 7, and the diameter direction The two elastic clip assemblies 82 facing each other can clamp the pipe 7 in the horizontal direction, wherein the left and right sides of the opening of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com