Power distribution device for rotating target

A power distribution device and rotating target technology, applied in the direction of flexible/rotatable wire connectors, circuits, electrical components, etc., can solve the problems of increased manufacturing and maintenance costs, difficult maintenance, and the inability to separate the integrated structure. Ease of maintenance and replacement, smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

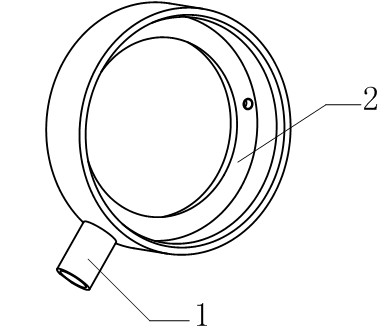

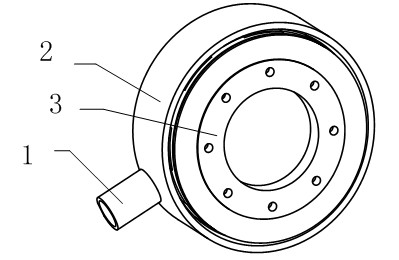

[0012] Such as Figure 1~3 The shown power distribution device for rotating targets includes a conductive rod head 1 , and its special feature is that a receiving groove 2 is provided at the top of the conductive rod head 1 used in the present invention. At the same time, an electrode carbon brush assembly is arranged in the accommodation tank 2 .

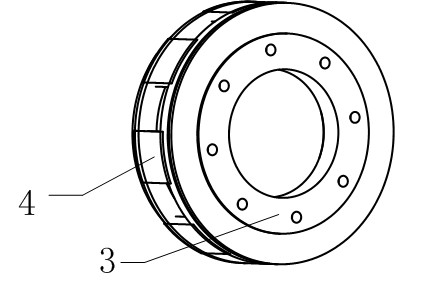

[0013] In view of a preferred embodiment of the present invention, in order to facilitate the subsequent smooth operation of the rotating target, and to meet the current stability in the power distribution process, the electrode carbon brush assembly includes an electrode ring 3, the electrode ring 3 Graphite flakes 4 are distributed on the outer circumference.

[0014] Further, through multiple comparison tests, it is found that the equidistant distribution of the graphite sheets 4 can maintain the overall power distribution effect in a relatively optimized state, which is beneficial to the operation of the target component in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com