Internal combustion locomotive exhausting louver

A technology for diesel locomotives and blinds, which is applied to windows, vehicle parts, windshields, etc., can solve problems such as poor water resistance, and achieve the effects of preventing falling off, facilitating maintenance and replacement, and facilitating maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

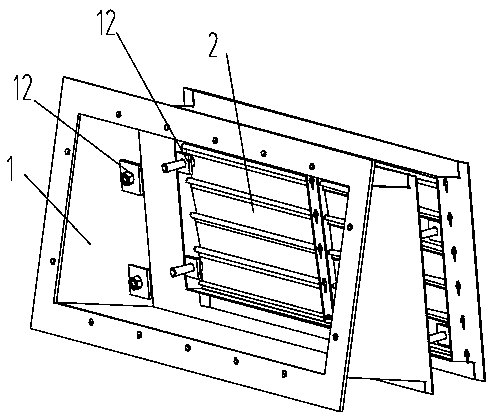

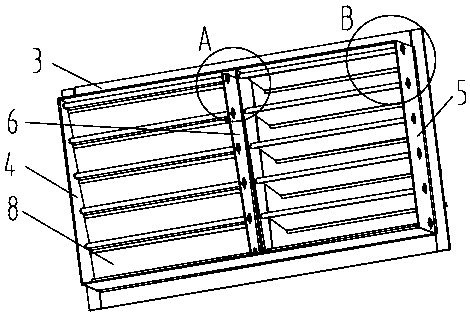

[0017] Such as figure 1 It is a structural schematic diagram of the present invention, an exhaust louver for a diesel locomotive, comprising an air duct 1, the port of the air duct 1 is provided with an outer window frame 2, and the outer window frame 2 includes an outer frame 3, and the outer frame 3 has two A left side plate 4 and a right side plate 5 are welded on the side, a column 6 is welded in the middle of the outer frame 3 , and a blade 8 is connected between the column 6 and the left side plate 4 and the right side plate 5 through a blade shaft 7 .

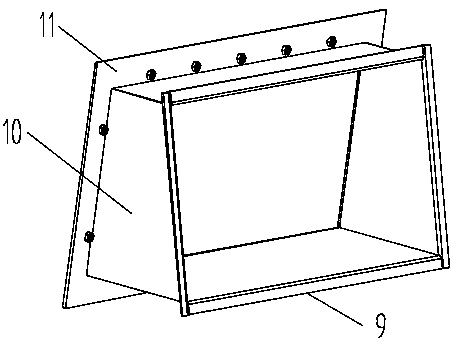

[0018] Such as figure 2 As shown, the blower 1 is made up of a blower frame 9 , a side plate 10 and a fixing seat 11 .

[0019] Such as image 3 As shown, the outer frame 3 of the outer window frame 2 and the inner side of the side plate 10 of the air duct 1 are welded with mounting seats 12 corresponding to each other.

[0020] combine Figure 3-5 As shown, the left side plate 4, the right side plate 5 and the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com