House roof waterproof construction technology based on waterproof rolls

A technology of waterproof roll material and construction technology, which is applied to roofs using flexible materials, building roofs, roof insulation materials, etc., to achieve the effects of light weight, convenient operation and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

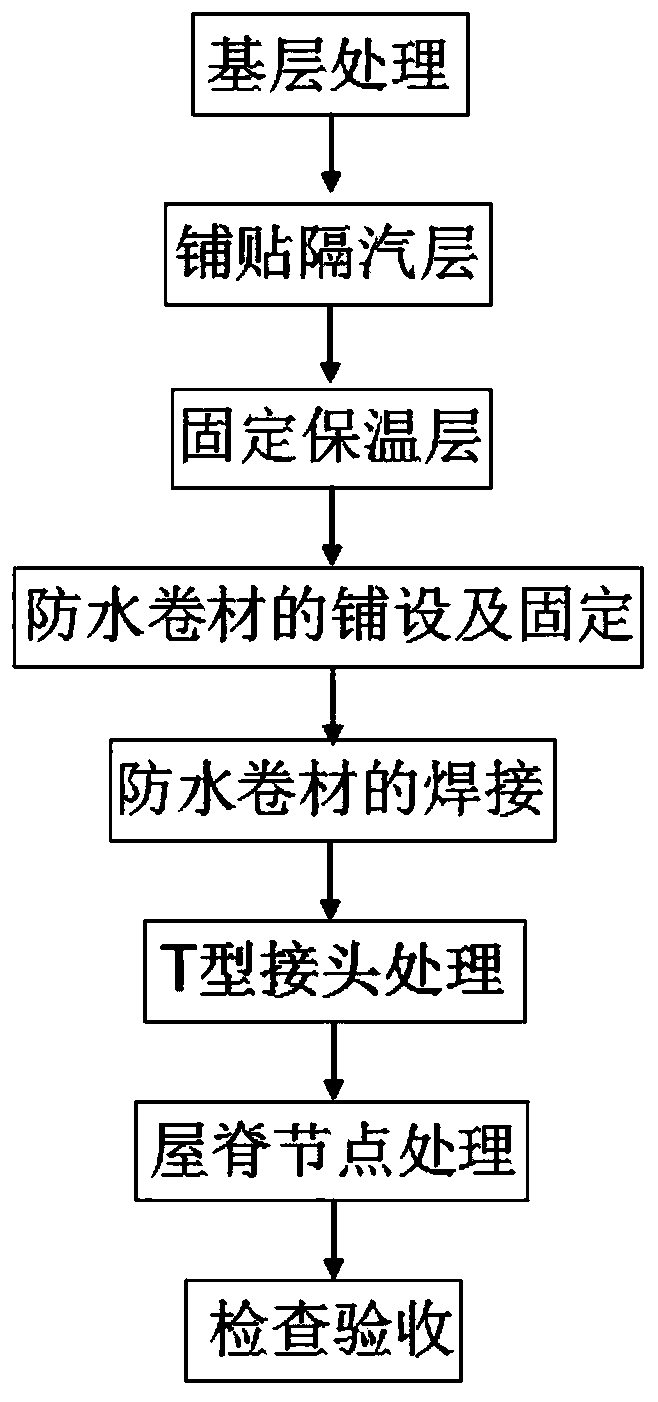

[0042] Such as figure 1 Shown, a kind of house roof waterproofing construction technology based on waterproofing membrane, comprises the following steps:

[0043] (1) Grassroots treatment

[0044] (1) Lay the profiled steel plate above the main structure of the roof of the house and connect it closely with the main structure. The connection between the profiled steel plates should be smooth and continuous, without any sharp protrusions, so as not to pierce and cut the vapor barrier layer and reinforcing rib TPO waterproof membrane.

[0045] (2) Before laying the reinforced TPO waterproof membrane, remove debris and foreign objects on the base.

[0046] (2) Laying vapor barrier

[0047] (1) Lay the PE film vapor barrier layer on the base layer, and pay attention to keep it straight when laying.

[0048] (2) Adjacent PE film vapor barrier layers are lapped by 8cm, and the lap joints are bonded and compacted with 10×1mm butyl tape to ensure that the indoor air is isolated and...

Embodiment 2

[0064] Such as figure 1 Shown, a kind of house roof waterproofing construction technology based on waterproofing membrane, comprises the following steps:

[0065] (1) Grassroots treatment

[0066] (1) Lay the profiled steel plate above the main structure of the roof of the house and connect it closely with the main structure. The connection between the profiled steel plates should be smooth and continuous, without any sharp protrusions, so as not to pierce and cut the vapor barrier layer and reinforcing rib TPO waterproof membrane.

[0067] (2) Before laying the reinforced TPO waterproof membrane, remove debris and foreign objects on the base.

[0068] (2) Laying vapor barrier

[0069] (1) Lay the PE film vapor barrier layer on the base layer, and pay attention to keep it straight when laying.

[0070] (2) Adjacent PE film vapor barrier layers are lapped by 12cm, and the lap joints are bonded and compacted with 10×1mm butyl tape to ensure that the indoor air is isolated an...

Embodiment 3

[0086] Such as figure 1 Shown, a kind of house roof waterproofing construction technology based on waterproofing membrane, comprises the following steps:

[0087] (1) Grassroots treatment

[0088] (1) Lay the profiled steel plate above the main structure of the roof of the house and connect it closely with the main structure. The connection between the profiled steel plates should be smooth and continuous, without any sharp protrusions, so as not to pierce and cut the vapor barrier layer and reinforcing rib TPO waterproof membrane.

[0089] (2) Before laying the reinforced TPO waterproof membrane, remove debris and foreign objects on the base.

[0090] (2) Laying vapor barrier

[0091] (1) Lay the PE film vapor barrier layer on the base layer, and pay attention to keep it straight when laying.

[0092] (2) Adjacent PE film vapor barrier layers are lapped by 10cm, and the lap joints are bonded and compacted with 10×1mm butyl tape to ensure that the indoor air is isolated an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com