Anti-corrosion cable equipped with thermal-insulating protection cover and assembling and mounting method for anti-corrosion cable

A protective cover, anti-corrosion technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of difficulty in flexible implementation, reducing the applicable range of cables, and unfavorable on-site assembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

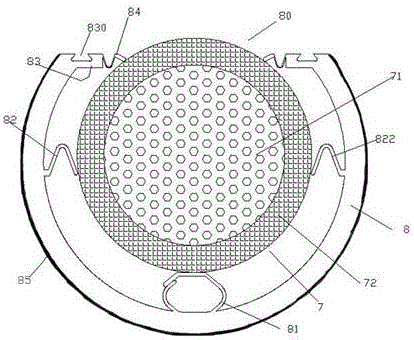

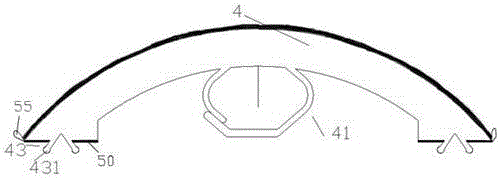

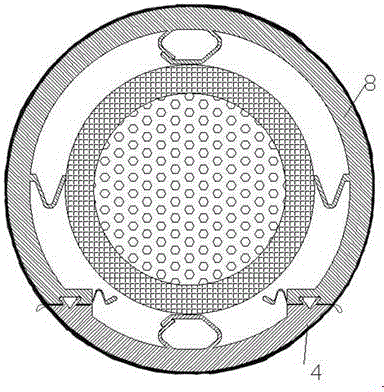

[0013] Combine below Figure 1-5 The present invention will be described in detail.

[0014] An anti-corrosion cable with a heat insulation shield according to an embodiment includes a cable body 7 composed of a cable core 71 and an insulating wrapping layer 72 and a heat insulation shield, wherein the heat insulation shield includes a The main accommodating part 8 which is a larger round section cylinder and the cover part 4 which is a smaller round section cylinder are composed of a cylinder, wherein the bottom of the main accommodating part 8 and the cover part 4 Elastic countertop platform pipe fittings 81, 41 are arranged symmetrically on the top of the top, and elastic clip parts 82 are symmetrically arranged at opposite parts in the diameter direction of the main accommodating part 8, so that the two elastic countertop platform pipe parts 81 , 41 can form the clamping in the vertical direction of the cable body 7, and the two elastic clip parts 82 can form the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com