Composite heat-insulating brick system

A technology of composite thermal insulation and thermal insulation materials, which is applied in the field of thermal insulation and energy saving of buildings, can solve the problems of poor durability, complicated construction procedures, and high difficulty in preparation, and achieve the effects of low maintenance costs during the service period, easy on-site masonry construction, and broad development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

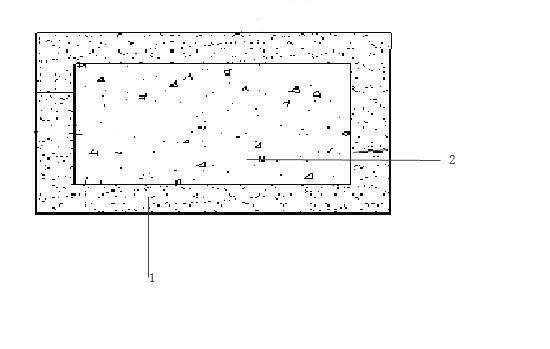

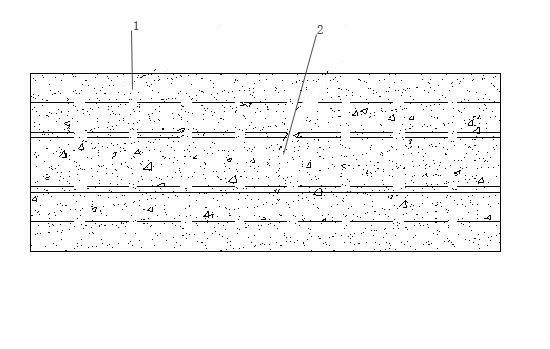

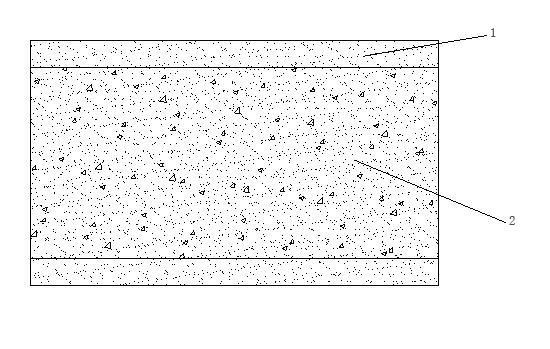

[0015] A composite thermal insulation brick system, including a structural part 1 and a thermal insulation part 2. The structural part 1 is composed of two interlocking L-shaped bodies. The L-shaped body is made of cement slurry, cement mortar or sintered clay. Two L-shaped bodies are occluded to form a cuboid with a cavity inside, and the inside of the cuboid is filled with thermal insulation materials such as foamed polystyrene organic thermal insulation materials, thermal insulation mortar or foamed concrete, and constitutes the thermal insulation part 2 .

[0016] There are two ways to form and build the composite insulation brick system:

[0017] (1): 1. The structural part and the thermal insulation part of the thermal insulation system are prefabricated in advance; 2. The thermal insulation part of the corresponding size is placed on an L-shaped body, and an adhesive can be used to bond the thermal insulation part and the structural part for convenience. The first L-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com