Sealing and heat insulating device for wrapped insulated tubing and manufacturing method thereof

A technology of thermal insulation oil pipe and thermal insulation device, which is applied to drill pipes, casings, drilling equipment, etc., can solve the problems of decreased thermal insulation effect, influence of thermal insulation effect, poor thermal insulation, etc., so as to reduce the loss of the temperature of crude oil itself. , Reduce the cost of oil extraction, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

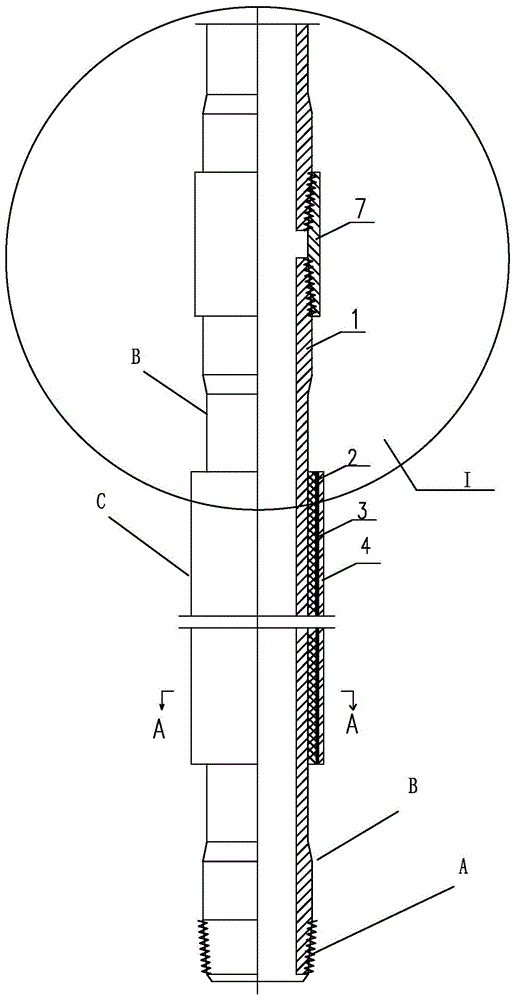

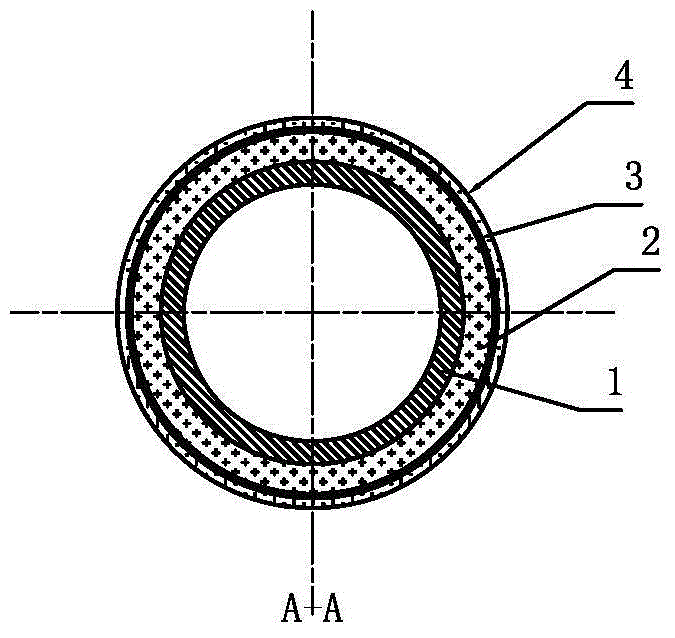

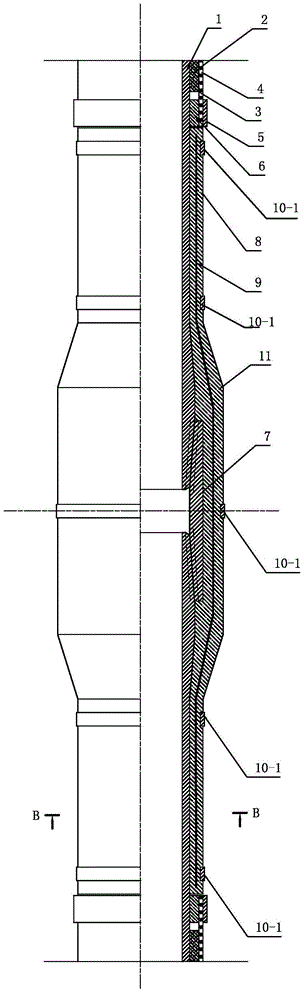

[0026] The structure of a heat-insulating oil pipe sealing and heat-insulating device wrapped in the present invention is described in detail as follows, see figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0027] A sealing and heat insulation device for an externally wrapped heat-insulating oil pipe. The two ends of the oil pipe 1 are threaded sections A processed with external threads, and the parts close to the threaded sections at both ends are two operating sections B. The oil pipe part is the middle section C; in the middle section C of the oil pipe 1, the outer wall of the oil pipe 1 is coated with a layer of heat insulation layer 2, and the outer wall of the heat insulation layer 2 is wrapped with a layer of heat insulation layer To protect the steel belt 3, a layer of anti-corrosion protection layer 4 is uniformly wrapped on the outside of the steel belt 3; at the coupling collar 7 of the oil pipe 1 and the operation section B, two prefabricated The butted sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com