Hopper for combined weighing scale

A combined scale and hopper technology, applied in the field of combined scale equipment, can solve the problems of difficult cleaning of the hopper, affecting the quality of materials, increasing production costs, etc., achieving the effects of easy disassembly and maintenance, ensuring packaging quality, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

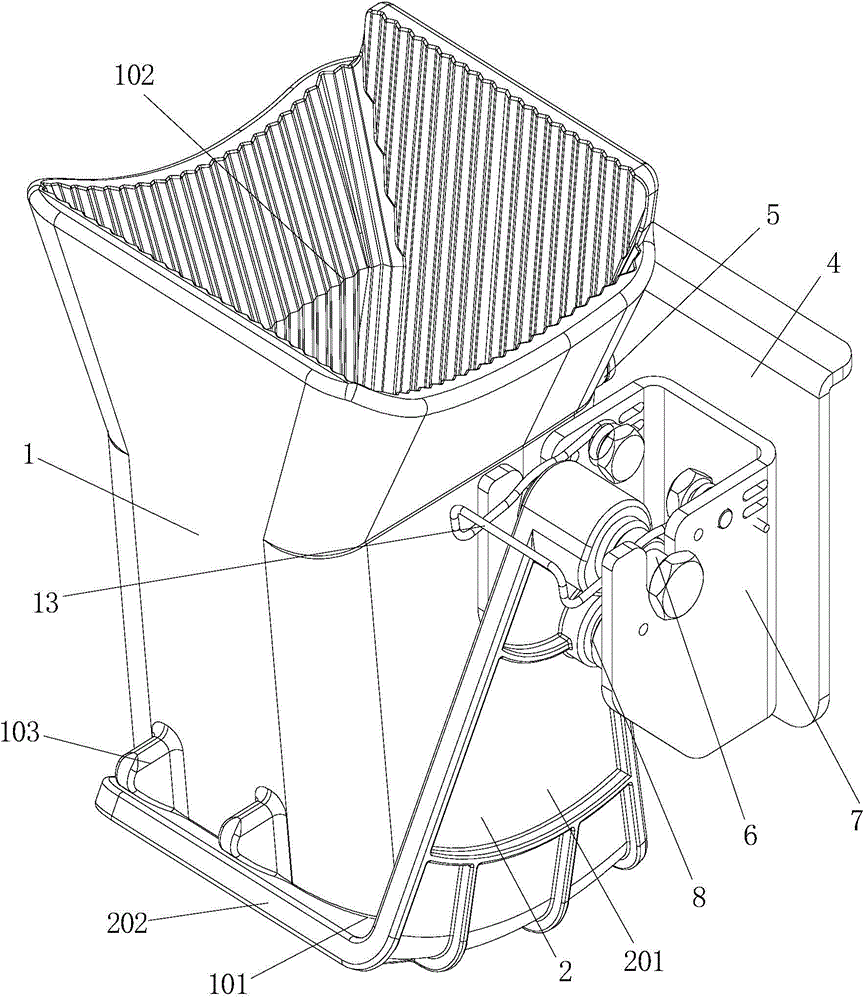

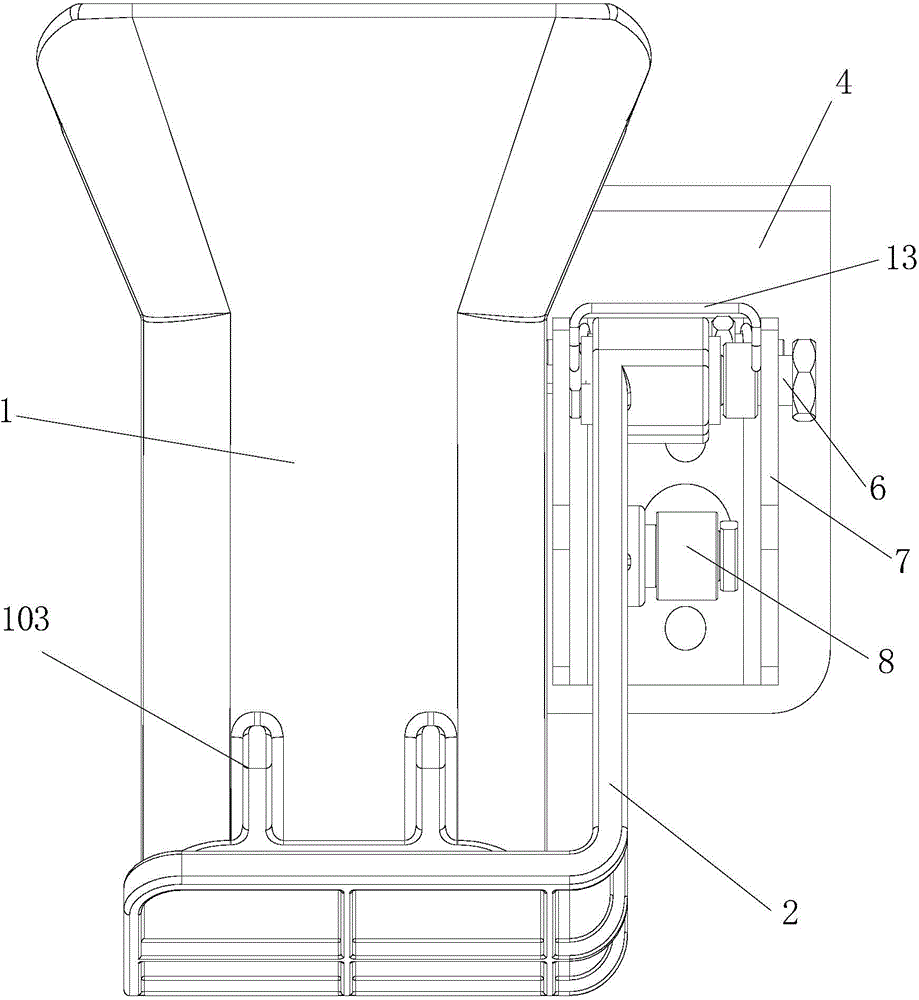

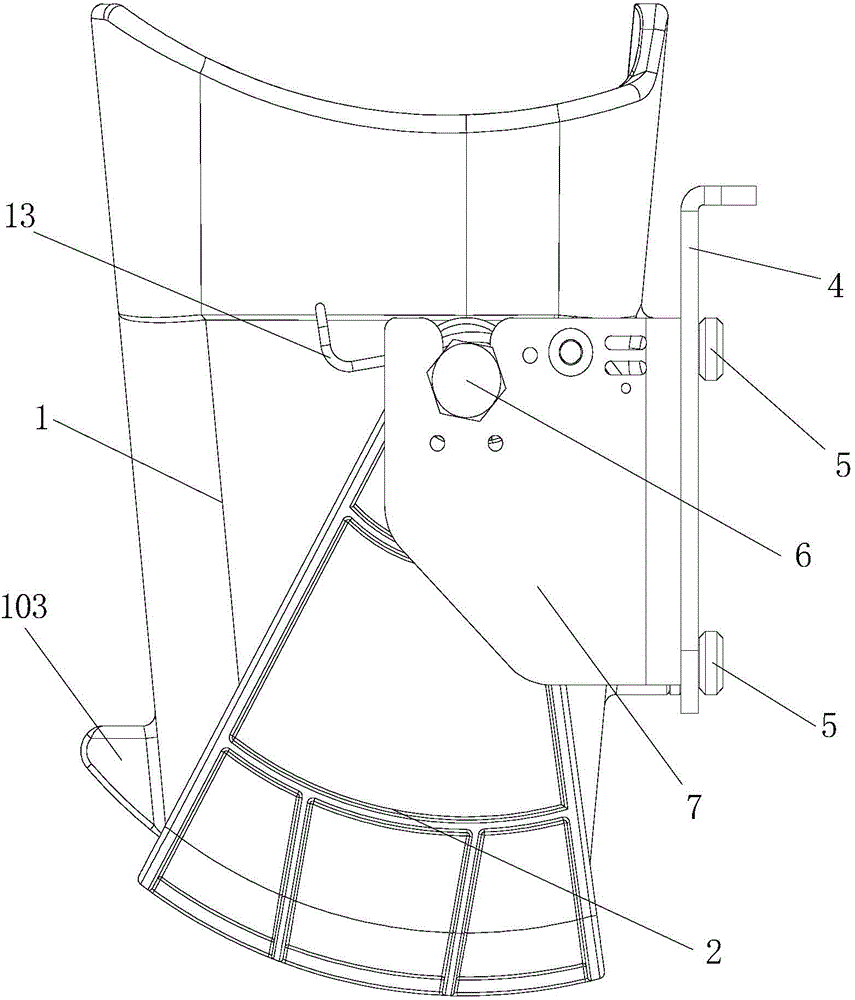

[0032] like Figure 1 to Figure 8 The shown hopper for the combination scale includes a bucket body 1, a bucket door 2, a suspension mechanism, a driving device and a push-pull rod 3; The pull rod 3 is driven and connected, the push-pull rod 3 is driven and connected with the bucket door 2, and the bucket door 2 is attached to the discharge port 101 at the bottom of the bucket body 1; when the driving device drives the push-pull rod 3 to move forward and backward along a straight line, the bucket door 2 correspondingly The outer edge of the discharge opening 101 of the body 1 slides open or closes.

[0033] like figure 1 , figure 2 , image 3 and Figure 8 As shown, the suspension mechanism includes a suspension frame 4 and a suspension nail 5, the lower end of the suspension frame 4 is fixed on the installation frame, and the upper end of the suspension frame 4 is provided with a suspension hole 401 matched with the suspension nail 5; One end of the nail 5 is fixedly co...

Embodiment 2

[0043] This hopper that is used for combination balance is with embodiment 1 except following technical characteristics: as Figure 9 As shown, the hopper for the combination scale also includes 2 articulated shafts and 2 articulated frames, the 2 articulated frames are respectively installed on the two side walls of the bucket body, and the section of the hopper door is in the shape of "凵" , both sides of the upper end of the bucket door are respectively hinged with hinge shafts, the hinge shafts are suspended from the hinge frame, and one side wall of the bucket door is provided with a connecting shaft connected with a push-pull rod. This design can make the installation and movement of the Doumen more stable, and improve the reliability of the Doumen's work.

Embodiment 3

[0045] The hopper used for the combination scale is the same as the embodiment 1 except the following technical features: the hopper door is plate-shaped, and the side of the hopper door is fixedly connected with the driving device.

[0046] The driving device includes a cylinder, the cylinder is fixed on the installation frame, and the piston rod of the cylinder is fixedly connected to one end of the push-pull rod, and the other end of the push-pull rod is fixedly connected to the side of the bucket door.

[0047] The bucket door of this embodiment has a simple structure, is convenient to process and manufacture, and reduces production costs. When working, the piston rod of the cylinder is stretched out to make the bucket door move forward in a straight line. During the straight forward movement of the bucket door, the front lower end of the bucket body can scrape off the materials adhering to the bucket door, which can also play a role. Avoid wasting materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com