A nonlinear ultrasonic testing method for wind tower welds

A nonlinear ultrasonic and wind tower technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves. Good effect and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical scheme of the present invention is described in further detail below in conjunction with accompanying drawing and embodiment, but said embodiment is not intended to limit the present invention, and all adopt similar structures and similar changes of the present invention, all should be listed in the scope of protection of the present invention .

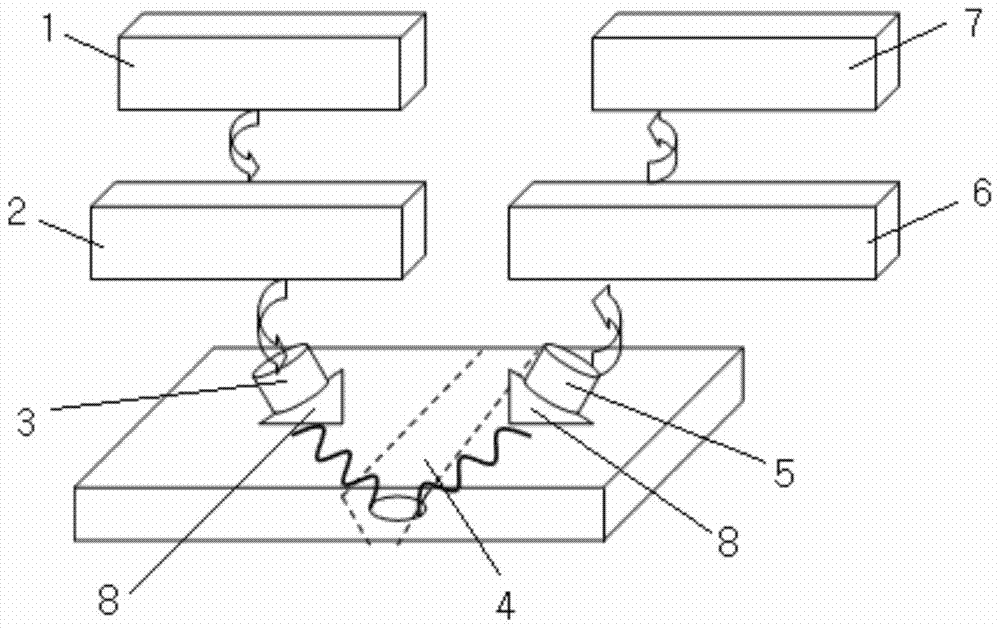

[0038] like figure 1 As shown, a kind of wind tower weld non-linear ultrasonic testing method provided by the present invention, the specific steps are as follows:

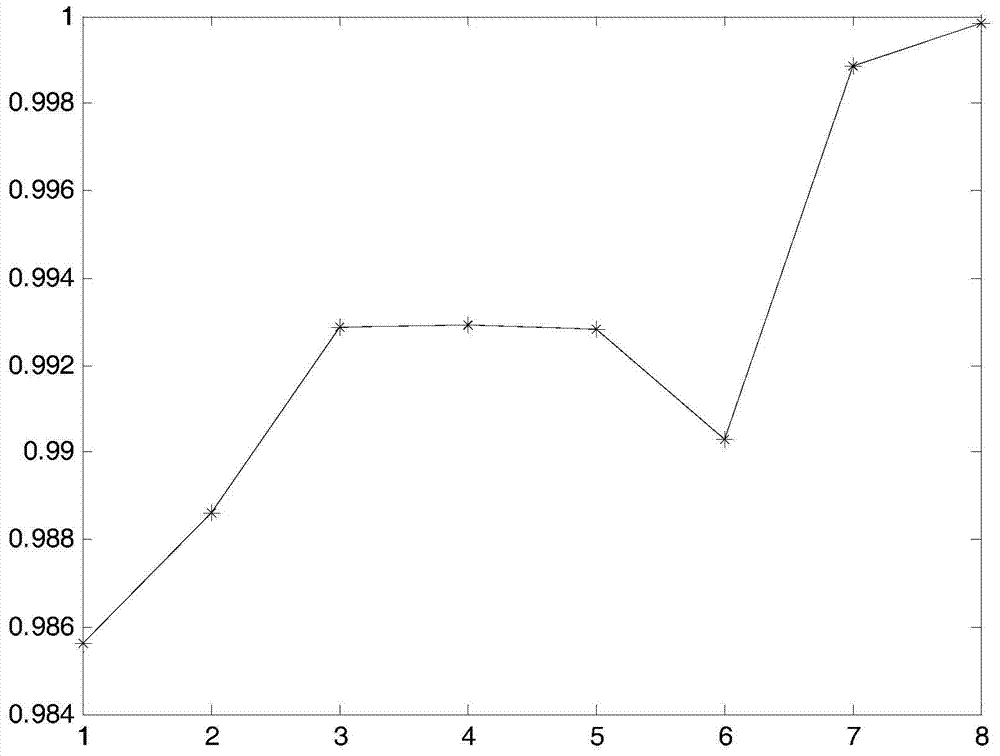

[0039] 1) For the target weld (the weld to be detected on the wind tower), use the ultrasonic transmitting device to perform ultrasonic multi-point scanning in the width direction and the length direction, and use the ultrasonic receiving device to collect the detection echo at each scanning point. The detection echo collected at each scanning point is sampled according to the same sampling method to obtain the detection echo waveform of each scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com