Kitchen garbage crushing and sorting equipment

A kitchen waste sorting technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of difficult separation of kitchen waste, less sundries in organic waste, and low organic waste composition, so as to increase Screening effect, stable and reliable material transportation, and the effect of preventing material agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

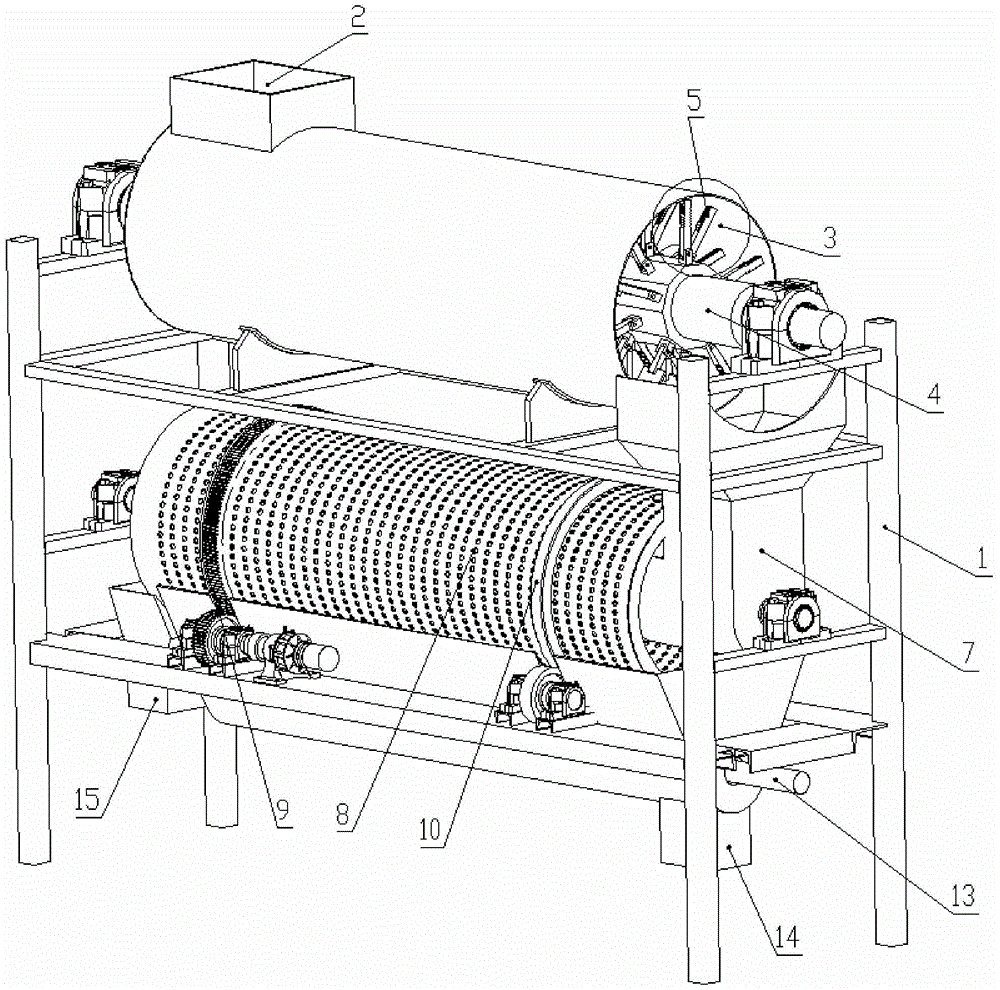

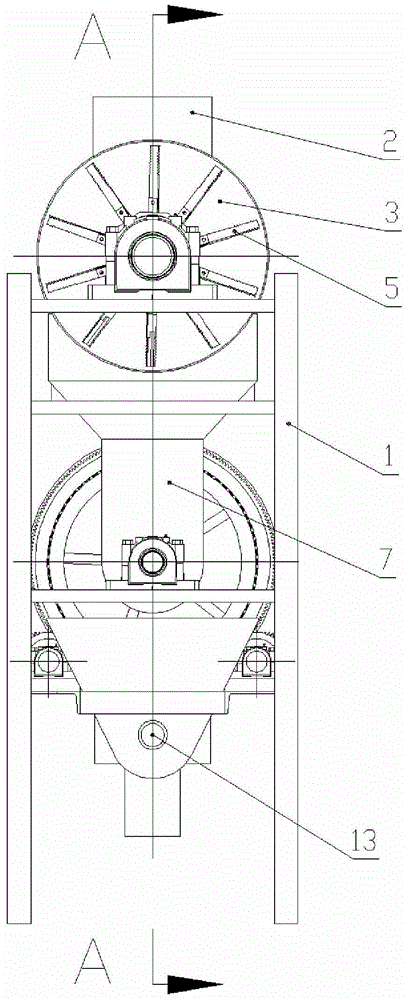

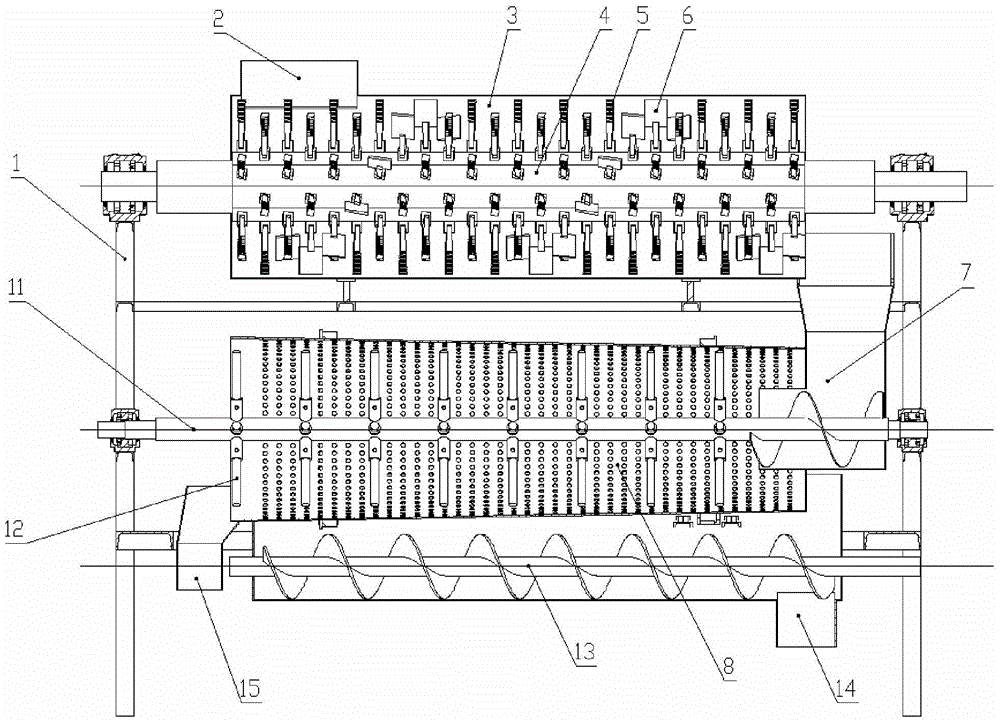

[0044] The present invention is illustrated with two specific product structures as examples.

[0045] See the section A-A diagram of the first embodiment, the present invention is mainly composed of a support 1, a crushing chamber 3 and a rotating drum 8, and kitchen waste enters the crushing chamber 3 from the feed port 2; the device in the crushing chamber 3 has a crushing rotating shaft 4 and the crushing rod 5, the crushing rod 5 and the crushing rotating shaft 4 adopt a hinge design (such as Figure 4 As shown), when the crushing rotating shaft is driven by the motor, the crushing rod 5 is thrown out by the centrifugal force, thereby crushing the radish, cucumber, pumpkin and other melon, fruit and vegetable organic waste in the kitchen waste, and the discharge of the crushing rod The density of the cloth is used to control the crushing degree of organic waste; because the crushing rod 5 and the crushing rotating shaft 4 are designed with hinges, when the kitchen waste c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com