Stapler

A technology of a stapler and a stand base, which is applied in the directions of manufacturing tools, staple staple tools, etc., can solve the problems of inconvenient staples, the inability to achieve the best labor-saving effect, and the long resistance arm of the upper cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

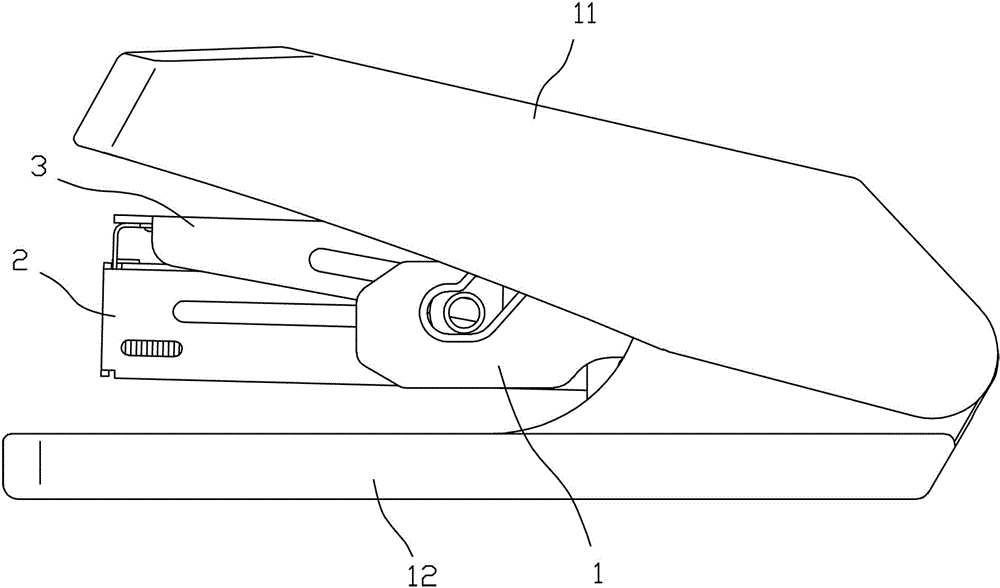

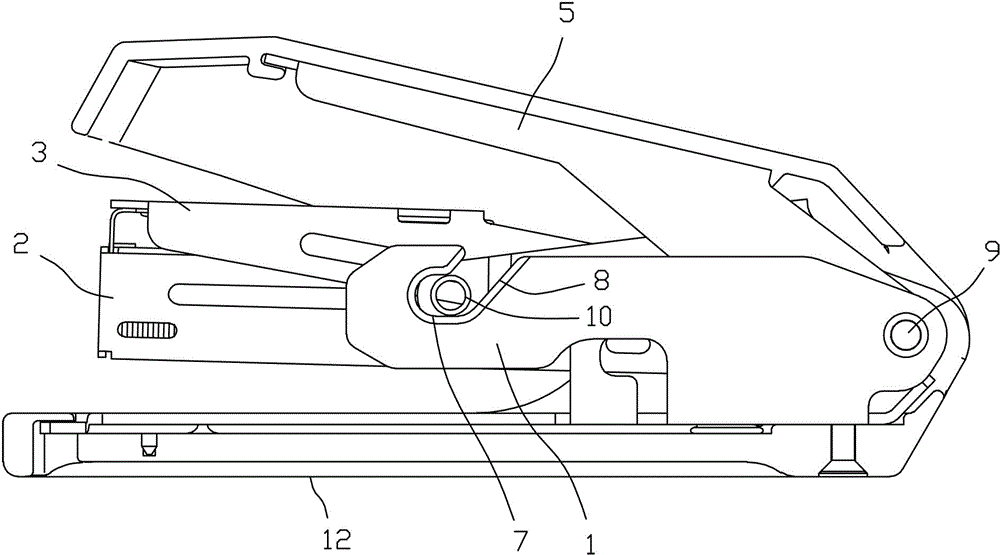

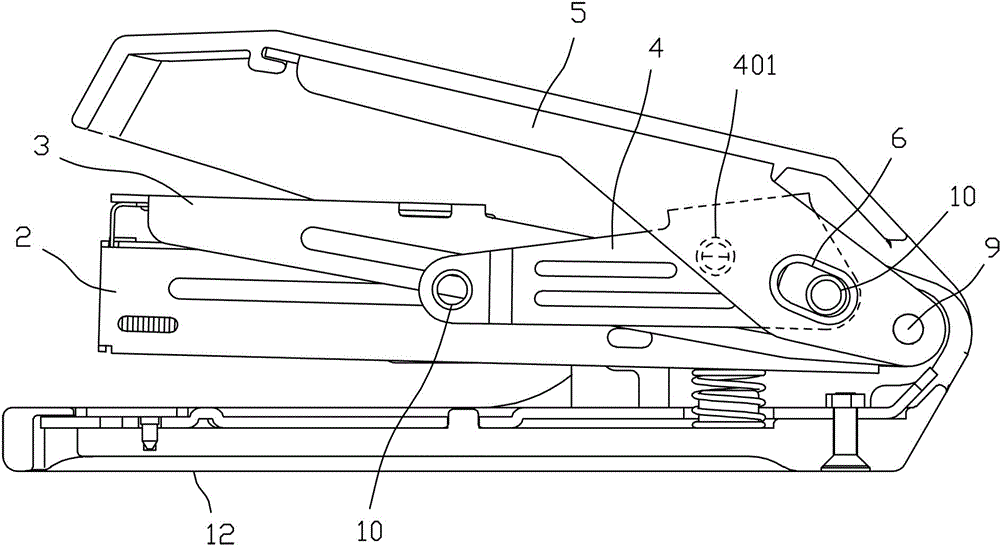

[0017] Depend on Figure 1~Figure 5 As shown, the stapler of the present invention comprises a support seat 1, a nail track 2, an upper blade assembly 3, a hinge 4 and a loam cake 5, and the tail ends of the nail track 2, the upper blade assembly 3 and the loam cake 5 are all Hinged to the tail end of the bracket base 1, so that the nail channel 2, the upper blade assembly 3 and the upper cover 5 can rotate relative to the bracket base 1, the side wall of the upper cover 5 is provided with a first guide, and one end of the hinge 4 Slidingly connected on the first guide part, the first guide part is arranged as a structure that can make one end of the hinge 4 move to the rear end of the upper cover 5 and press down when the upper cover 5 is pressed down.

[0018] As a preferred solution, the first guide part is a first chute 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com