Bolt cutters

A technology of bolt cutters and clamp handles, which is applied in the field of bolt cutters, and can solve the problems of difficulty in continuous work for a long time and amplifying the leverage ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

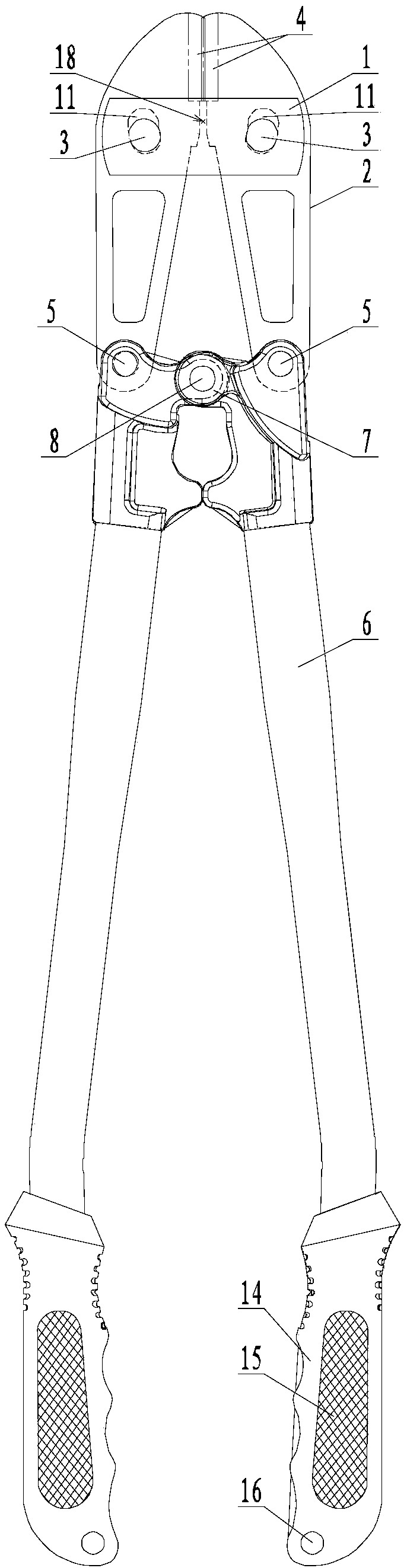

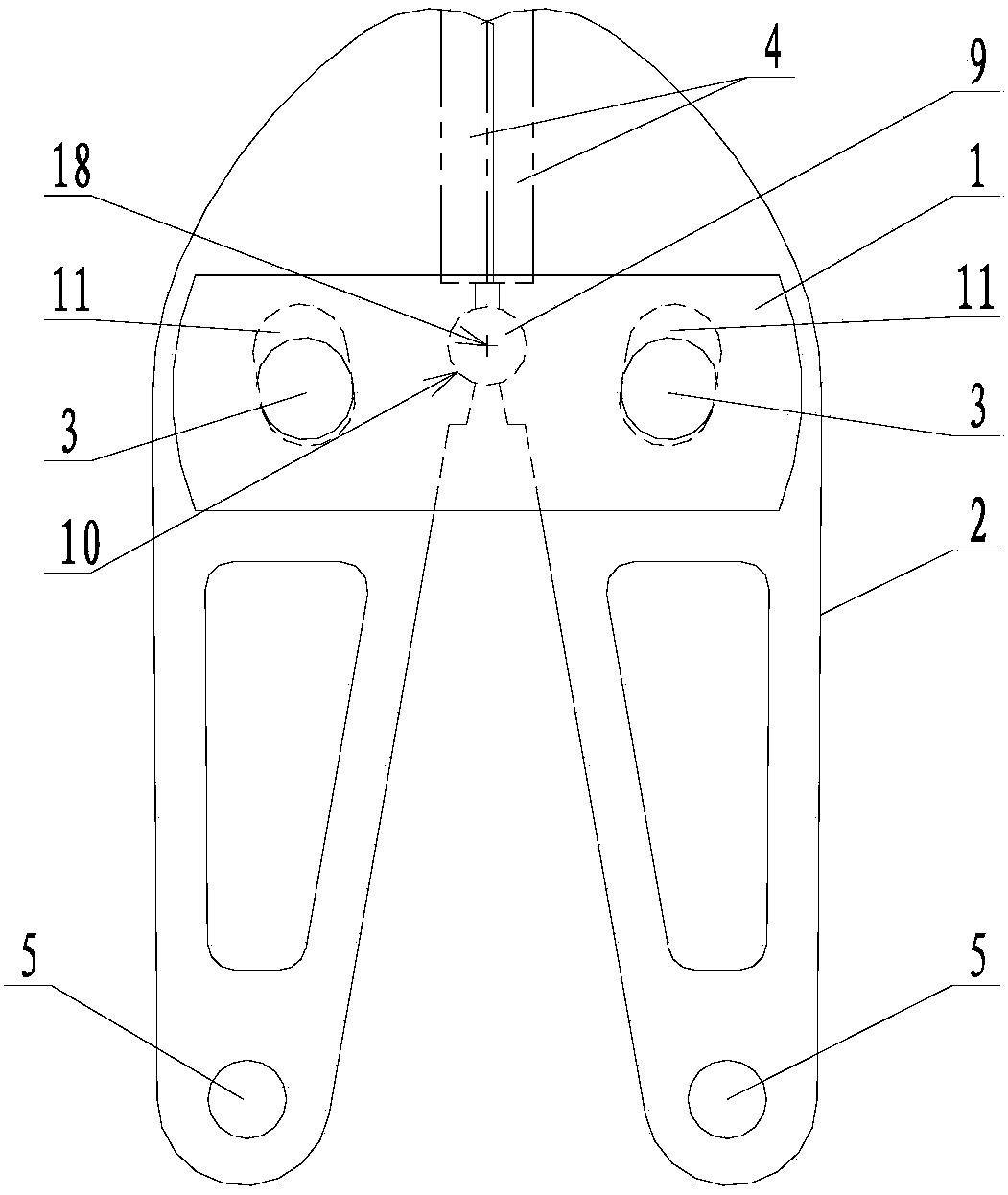

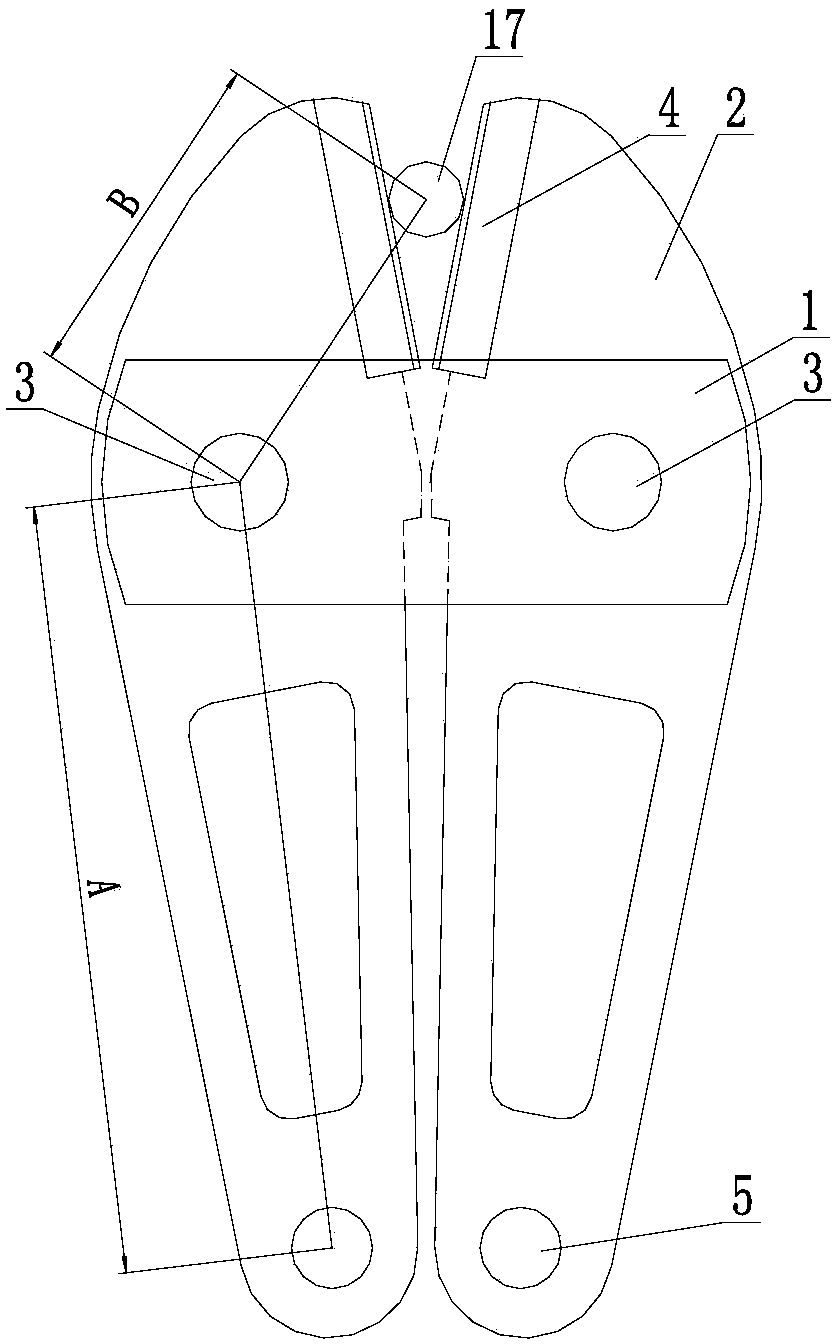

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 The shown bolt cutter includes two oppositely arranged splints 1, and two mutually opposite cutter heads 2 are arranged side by side between the two splints 1, and the two cutter heads 2 pass through a first pin shaft 3 and the two splints respectively. 1 is hinged, and the opposite sides of the front parts of the two cutter heads 2 are respectively provided with blades 4, and the rear ends of the two cutter heads 2 are respectively hinged with a pincer handle 6 through a second pin shaft 5, and the front ends of the two cutter handles 6 are provided with oppositely extending supports Arm 7, the two arms 7 are partially overlapped and the overlapped part is hinged together by a third pin 8, the cutter head 2 is provided with an arc-shaped hole 11 corresponding to the first pin 3 one-to-one, the The first pin 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com