A multi-directional shock absorbing buffer device

A buffer device and buffer body technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of easy damage, poor buffer effect, easy dislocation of disc springs, etc., and achieve improved buffering The force and the power arm are increased to improve the effect of friction and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

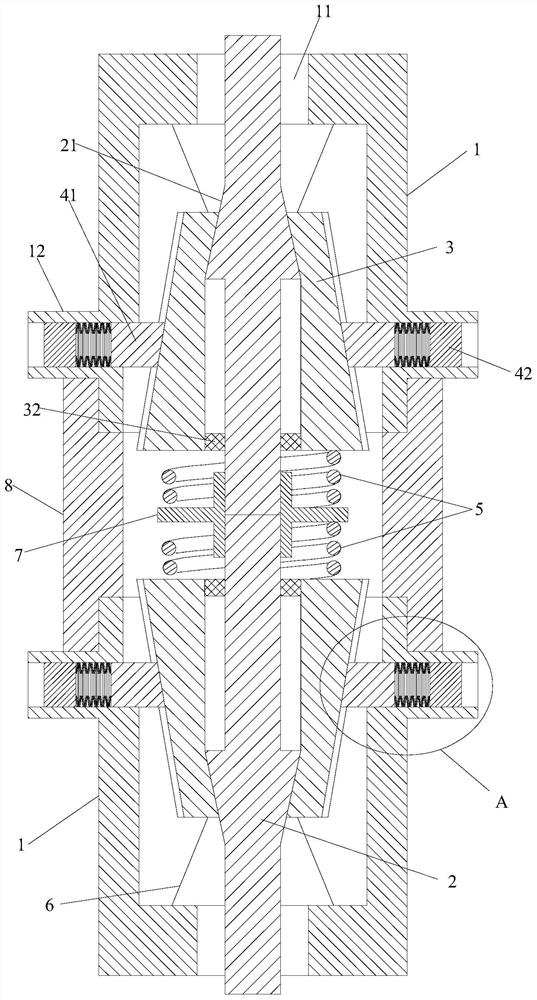

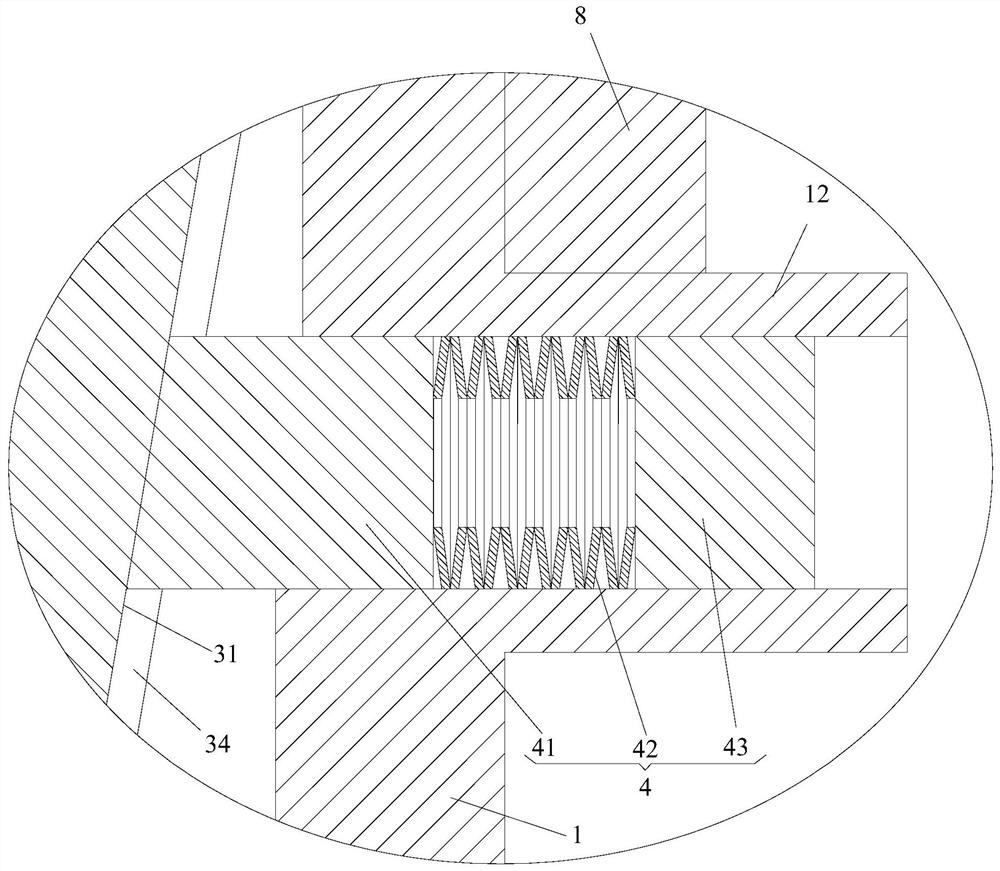

[0048] Such as figure 1 As shown, the present invention provides a multi-directional shock absorbing and buffering device, including two bases 1 that are combined together, and the adjacent ends of the two bases 1 are fixedly connected, and the connection method can be as follows figure 1 As shown in , it is connected through the connecting sleeve 8, or it can be directly connected, but it should be noted that a part of space should be reserved at the connection for the installation of the second elastic body 5 and the first buffer body;

[0049]For the two bases 1, it can adopt a sleeve-type structure, and a moving rod 2 is arranged in the two bases 1, and two first buffer bodies are symmetrically arranged on the moving rod 2, and the two first The buffer bodies are respectively arranged in the two bases 1 to form a buffer for the moving rod 2, wherein the moving rod 2 and the first buffer body can be displaced relative to the base 1, so the base 1 needs to have a space for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com