Mold for large-size uniparted hyperboloid injection molding part

A large-volume, hyperboloid technology, applied in the mold field of large-volume single-leaf hyperboloid injection molded parts, to achieve the effect of fast and convenient processing, omitting assembly and installation, and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described in conjunction with the following examples.

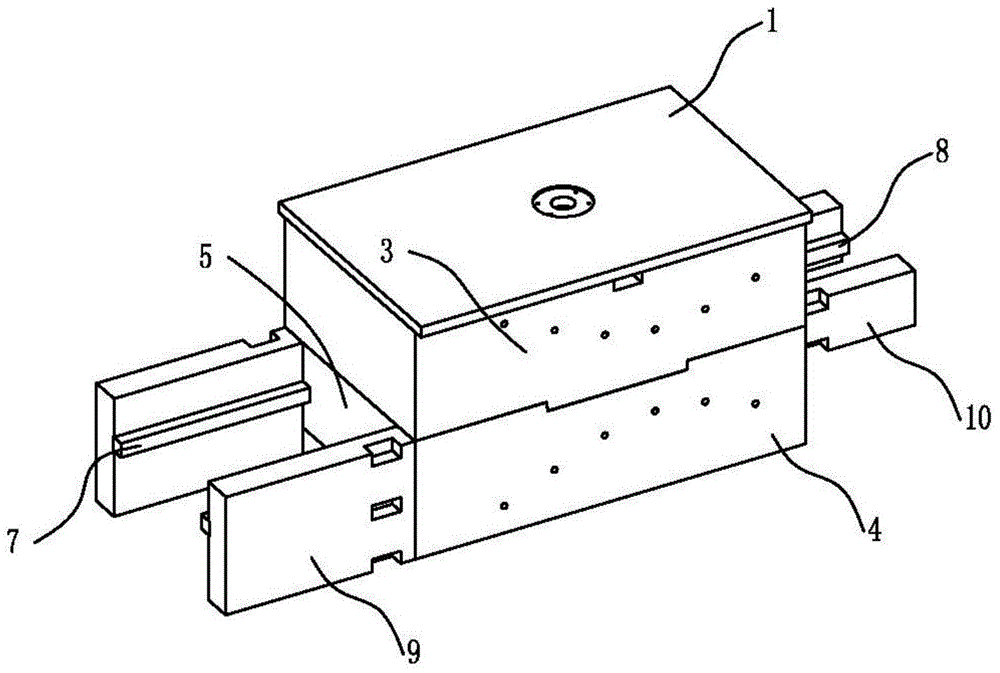

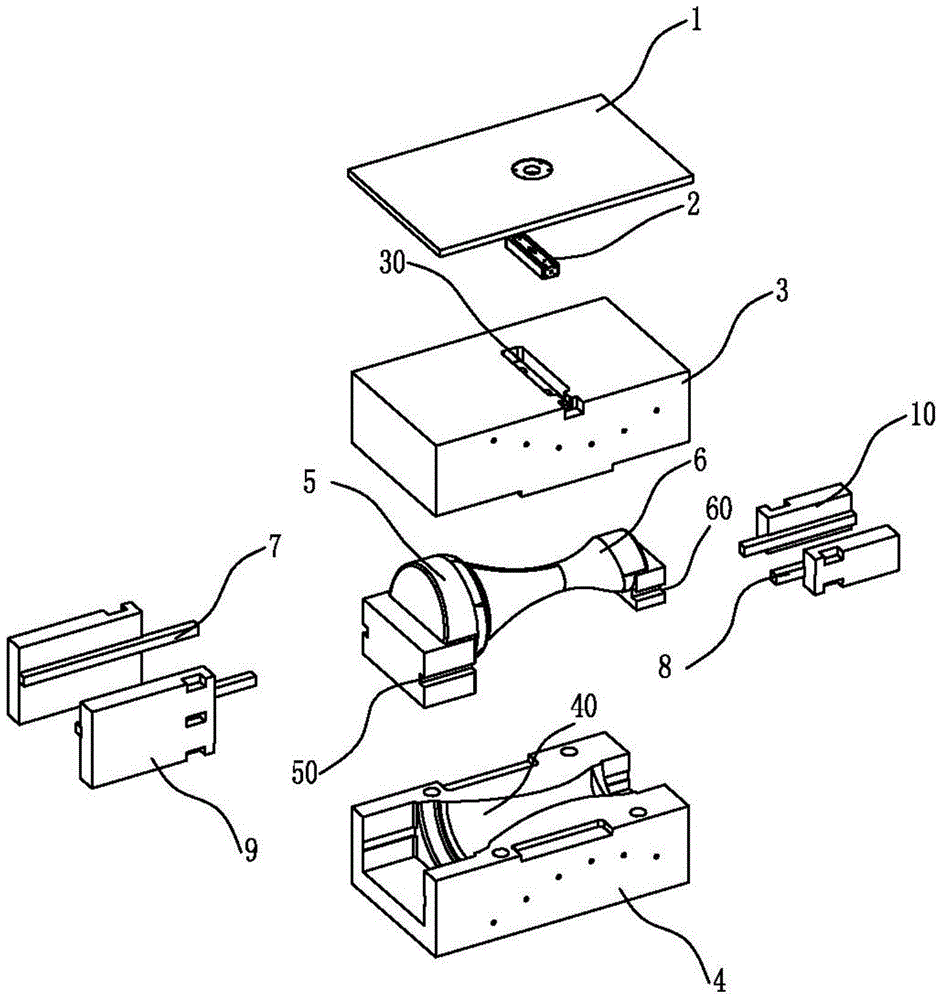

[0029] The mold of the large-volume single leaf hyperboloid injection molded part created by the present invention, such as figure 1 and figure 2 As shown, it includes a front template 1, a hot runner plate 2, an A mold 3, and a B mold 4 arranged sequentially from top to bottom, wherein, the A mold 3 is provided with an accommodating cavity 30 for accommodating the hot runner plate 2, see figure 2 , the hot runner plate 2 is embedded in the accommodating cavity 30 of the A mold 3 .

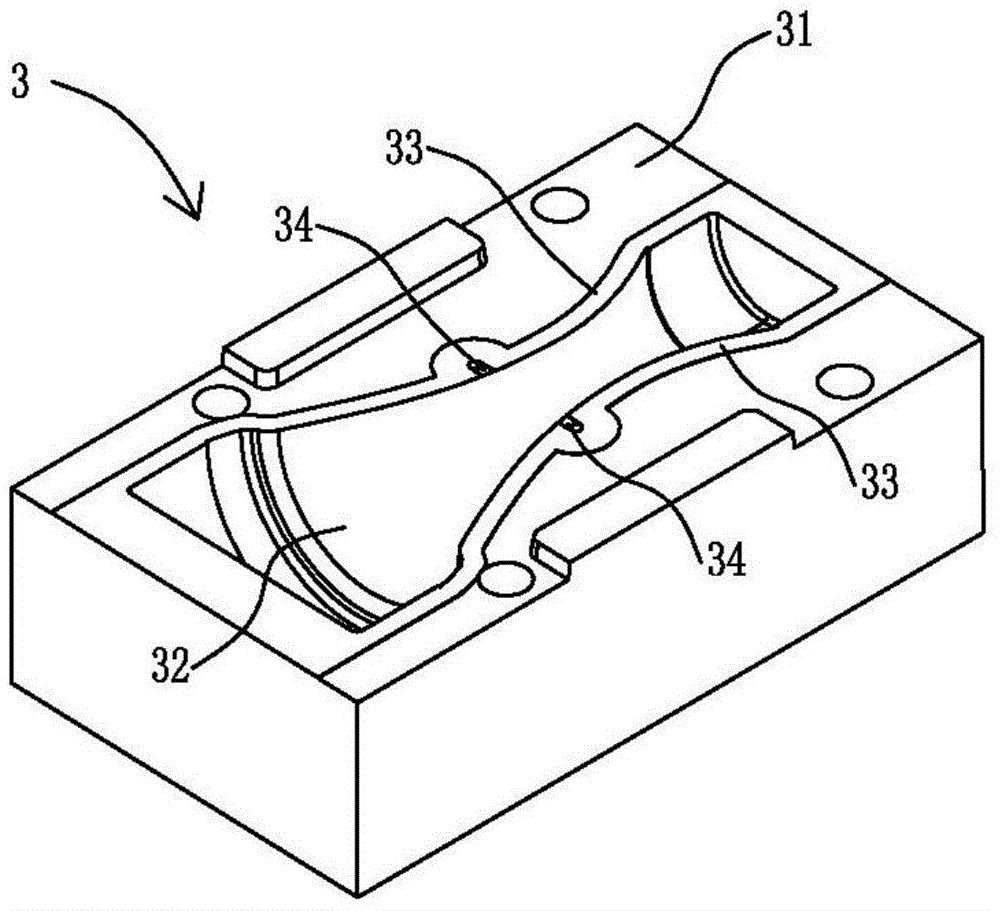

[0030] Such as image 3 As shown, the molding surface 31 of the A mold 3 is protruded with a cushion step 33 along the edge of the cavity 32 of the A mold 3. When the A mold 3 cooperates with the B mold 4, the cushion step 33 and the molding surface of the B mold 4 For contact, the height of the cushion step is preferably 0.5-1 mm. The bearing step 33 defines a runner groove 34 extending to the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com