Bend reducer of anti-explosion structure

An explosion-proof structure and corner technology, applied in the direction of elbows, pipes/pipe joints/pipes, siphons, etc., can solve the problems of increasing the overall size of the detection equipment, affecting the response time of the sensor, and insufficient detection gas, so as to improve the detection accuracy. , The effect of reliable explosion-proof performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

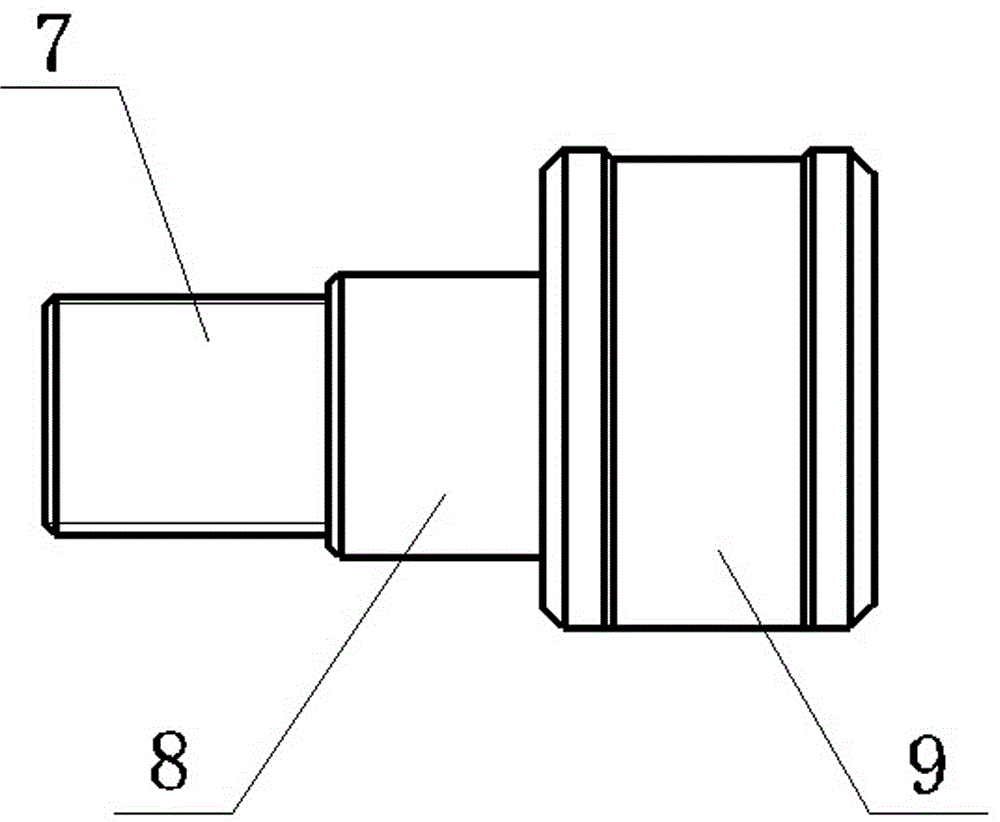

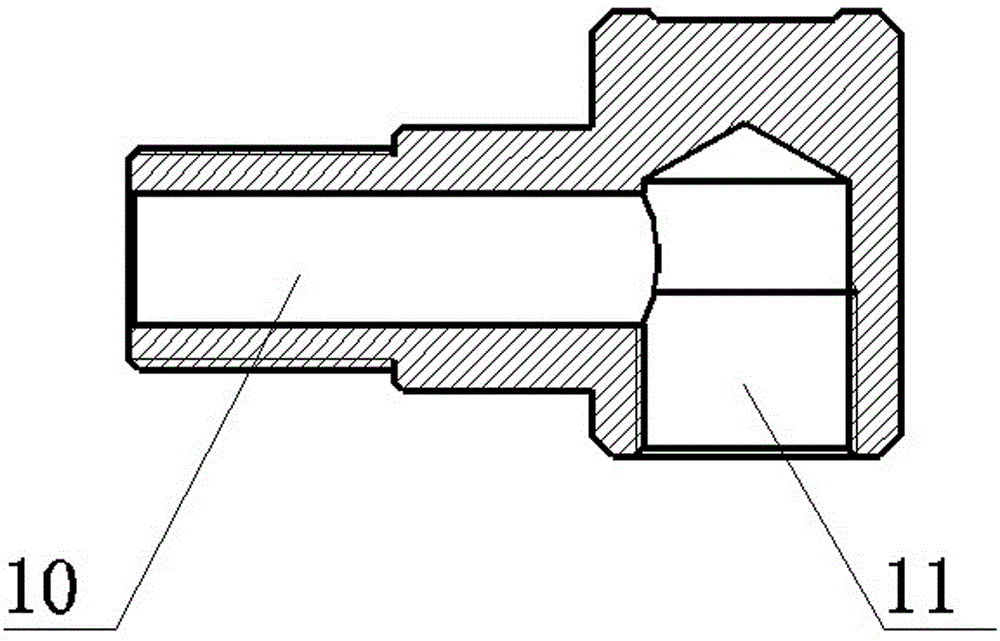

[0012] An angle reducer 1 of an explosion-proof structure, including a large shoulder 9, a small shoulder 8, and a front external thread 7; it is characterized in that: the large shoulder 9 is connected to the small shoulder 8, and the small shoulder 8 is connected to the front outer thread The thread 7; the connecting body composed of the large shoulder 9, the small shoulder 8 and the front external thread 7 forms a horizontal axis inner hole 10 and a vertical axis inner hole 11 inside.

specific Embodiment approach 2

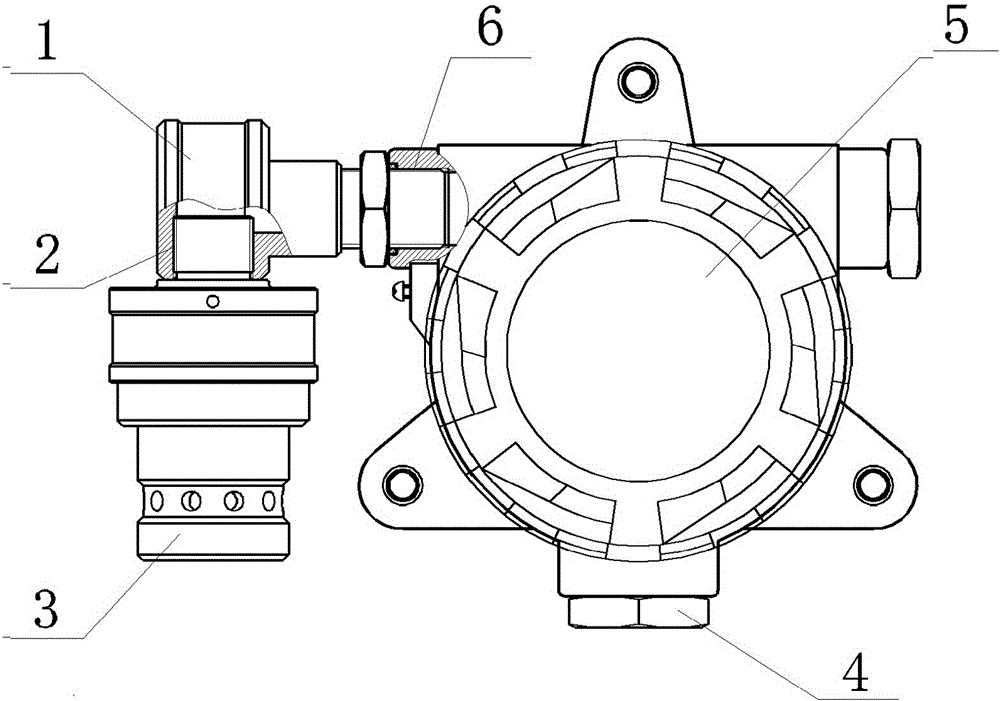

[0014] An angle reducer 1 with an explosion-proof structure includes a horizontal axis part and a vertical axis part. The horizontal axis part is composed of the front external thread 7, the small shoulder 8, and the horizontal axis inner hole 10. The front external thread 7 is connected with the inner screw interface of the detector 5 to form a horizontal thread explosion-proof structure 6; the vertical axis part is composed of the bottom internal thread, The large shoulder 9 and the inner hole 11 of the vertical axis are formed, and the internal thread at the bottom end is connected with the external thread of the sensor 3 to form a vertical thread explosion-proof structure 2 . The bottom of the detector 5 is provided with a detector bottom interface 4; the small shoulder 8 connects the front external thread 7 and the large shoulder 9, and the inner hole 10 of the horizontal axis and the inner hole 11 of the vertical axis form a cable connection cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com