A torque motor resistance torque testing system

A testing system and torque motor technology, applied in measurement devices, torque measurement, power measurement, etc., can solve problems such as low efficiency, inability to meet requirements, inability to accurately measure the relationship between rotation angle and resistance torque, etc., to improve measurement accuracy , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

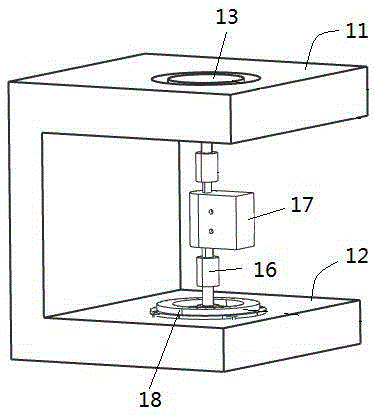

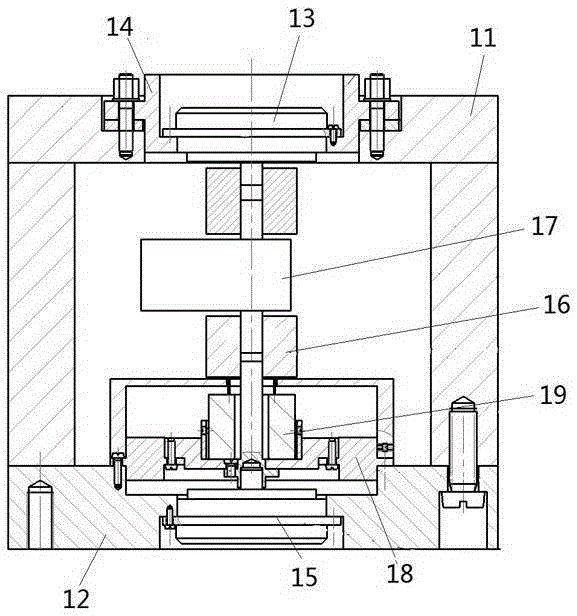

[0029] Embodiment 1 of the torque motor resistance torque test system, such as Figure 1-4 As shown, a resistance torque test bench 101 and an industrial control cabinet 102 are included.

[0030] The resistance test bench 101 is fixedly assembled on a base platform 103, and its shape is a side lying U-shape, including a tested motor mounting base 11 and a loading device mounting base 12, wherein the measured motor mounting base 11 and the loading device mounting base 12 are one The upper and lower are arranged opposite each other and each has a mounting hole. The installation holes located on the tested motor mounting base 11 and the loading device mounting base 12 are coaxial, and the mounting holes of the tested motor mounting base 11 are used for fixed assembly of the tested motor 13 (torque motor), which has a The flange connection hole of the motor 13 fixed connection, in the present embodiment, in order to realize the fixation of the tested motors of different models a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com