Prefabricated stainless steel chimney convenient to install and splice

A stainless steel, prefabricated technology, applied in the field of stainless steel products, can solve the problems of debris falling, low variability, unfavorable regular disassembly, etc., to increase the connection firmness, improve the degree of applicability, and improve the degree of stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

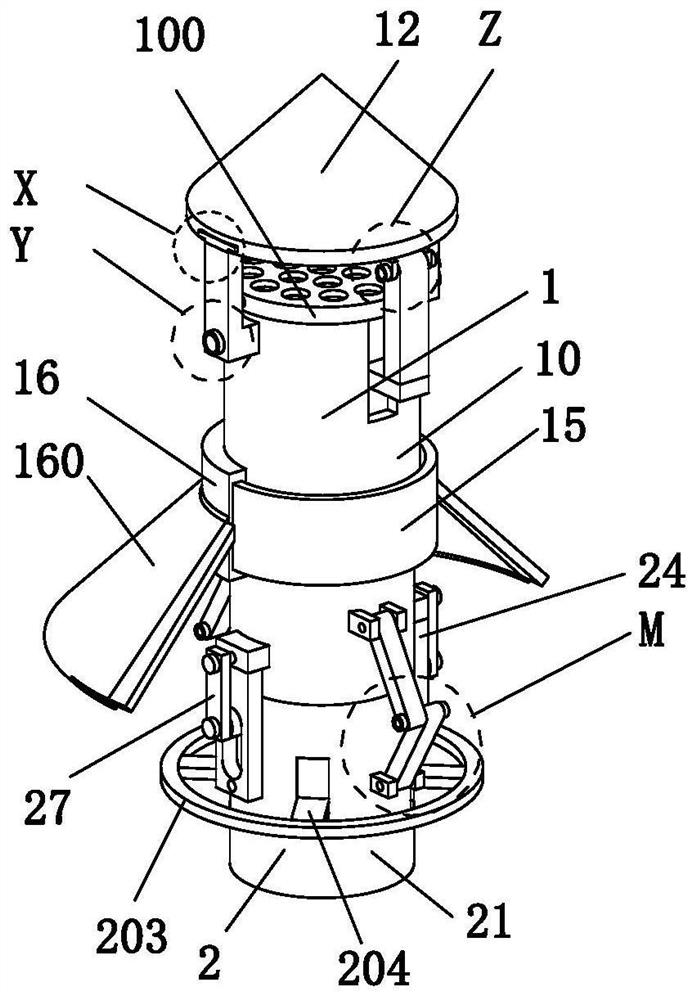

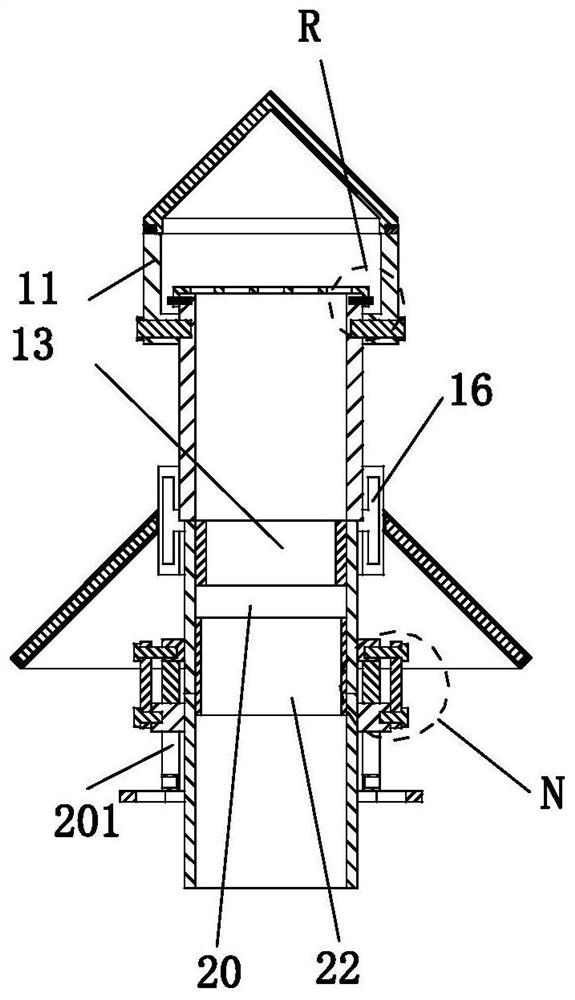

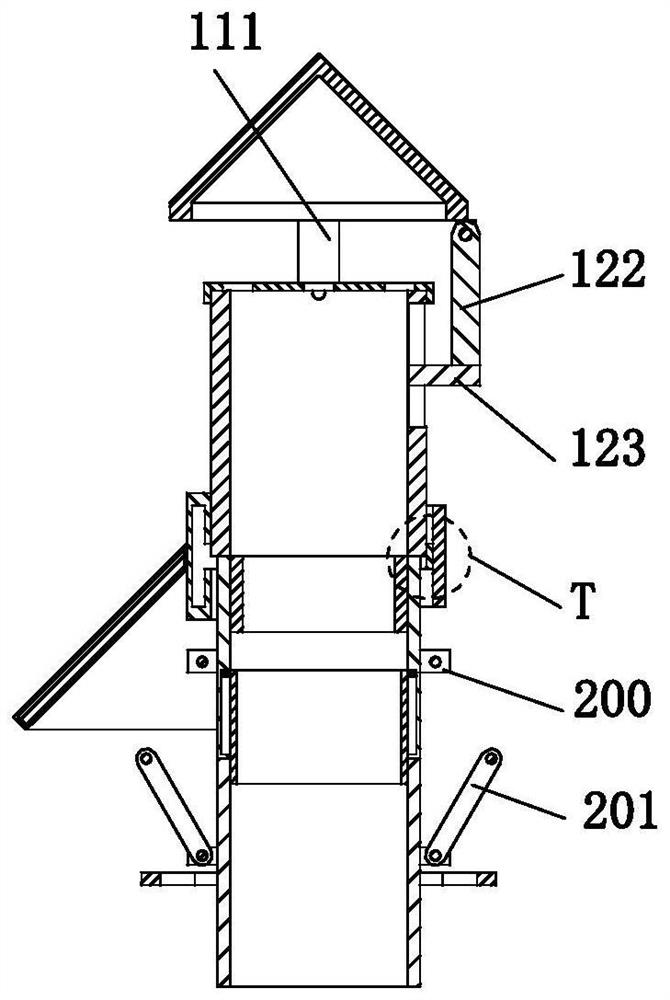

[0033] like Figure 1 to Figure 10 As shown, a prefabricated stainless steel chimney that is convenient for installation and splicing includes a splicing unit 1 and a rotating unit 2 , and the lower end of the splicing unit 1 is provided with a rotating unit 2 .

[0034] The splicing unit 1 includes a main chimney 10, a connector 11, a conical plate 12, an inner ring plate 13, a convex plate 14, an inner panel 15 and a semicircular ring plate 16, and the upper end of the main chimney 10 is symmetrically arranged on the outer wall. The connecting piece 11 is provided with a conical plate 12 between the upper ends of the connecting piece 11, the inside of the conical plate 12 is hollow, the lower end of the main chimney 10 is equipped with an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com