A shock-absorbing and vibration-isolation system for a hand-held electromagnetic riveting gun

An electromagnetic riveting gun and hand-held technology, which is applied in the field of shock absorption and vibration isolation systems, can solve problems such as the unsatisfactory effect of the buffer, and achieve the effect of simple structure, easy work completion, and comfortable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

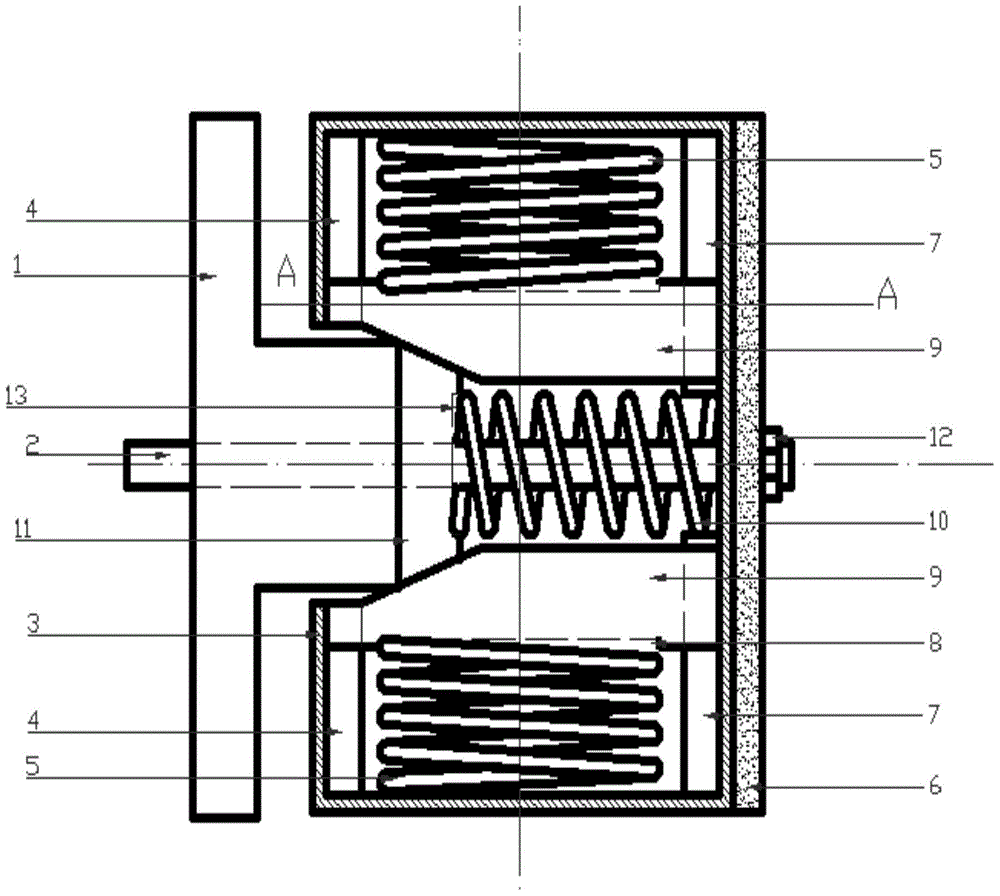

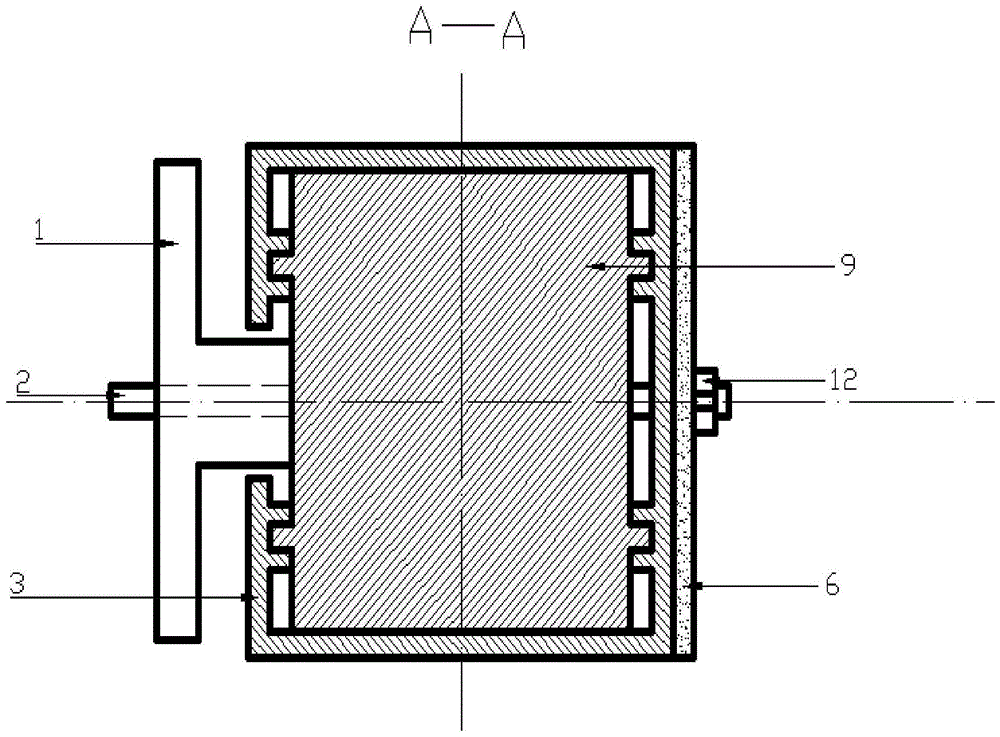

[0019] The invention provides a novel electromagnetic riveting gun buffer device which transforms the axial compression into a certain amount of circumferential compression through the inclined slider structure. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the invention.

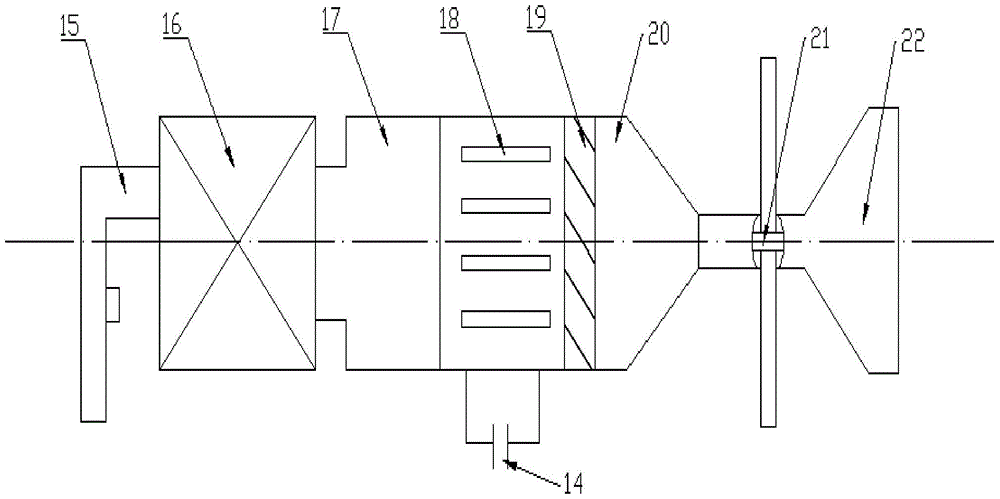

[0020] Such as figure 1 Shown, the structure diagram of traditional hand-held electromagnetic riveting gun, it is made up of capacitor group 14, handle 15, buffer 16, resilient body 17, primary coil 18, secondary coil 19, modulator 20, rivet 21, top iron 22 etc. composition, its working process is as follows:

[0021] 1) The capacitor bank 14 is discharged through the coil, and an eddy current repulsion force is generated between the primary coil 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com