Rubber tube coiler

A technology of coiling machine and rubber hose, which is applied in the field of rubber hose production equipment, can solve the problems of increasing the manufacturing cost of coiling equipment and increasing the difficulty of management of equipment accessories, and achieve the effects of reducing production cost, simple use, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

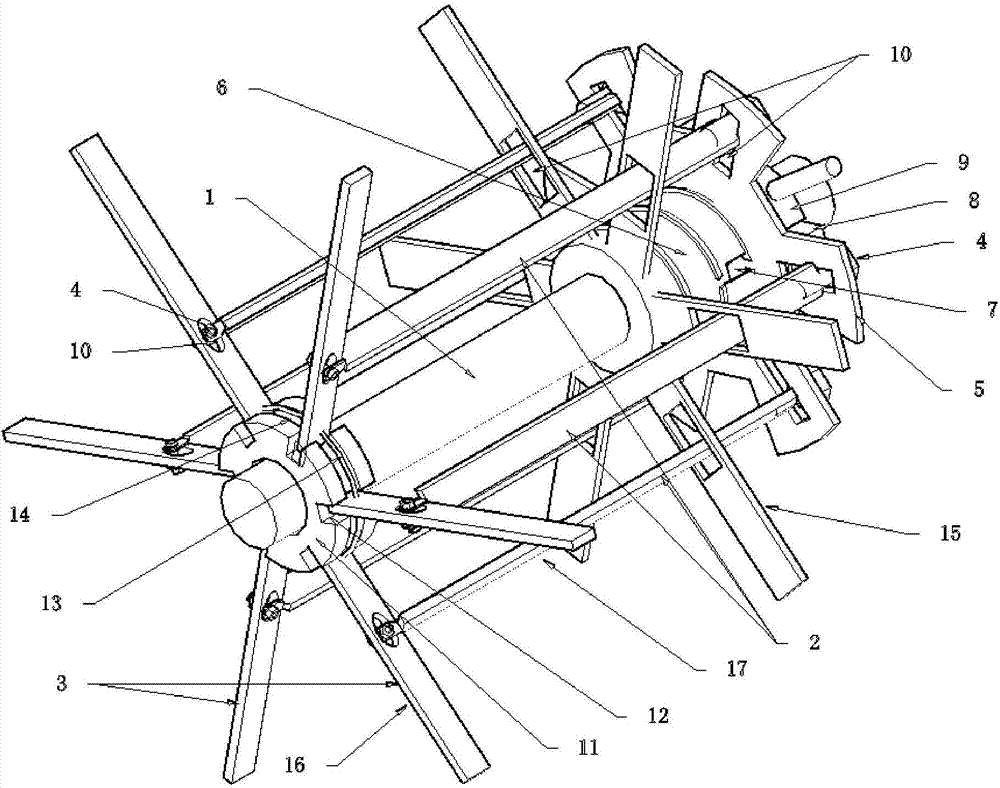

[0010] In order to further understand the technical solution of the present invention, the present invention will be further illustrated by the following embodiments in conjunction with the accompanying drawings. Such as figure 1 As shown, the hose reeling machine of this embodiment includes a rotating shaft and a corresponding winding disk connected to the rotating shaft 1, and the winding disk includes a reel and corresponding two stop disks. The reel is a fence-like reel 17 composed of several supporting bodies 2 evenly distributed around the rotating shaft 1 and along the axial direction of its length. The supporting body 2 in this embodiment is a cross-sectional shape of an arc. One of the two stop plates is a fence type stop plate 16, the other can be a common stop plate 15. The fence type stop plate 16 consists of several stop bodies evenly distributed around the axis of rotation along the radial direction of its length. Composition, the blocking body 3 in this embodime...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap