Floating device for power head of trenchless pipe laying rig

A drilling rig power head and floating device technology, which is applied in the direction of rotary drilling rigs, earthwork drilling, drilling equipment, etc., can solve the problems affecting the use of the power head floating device and the fracture of the connecting shaft, and achieves ingenious structure, water sealing, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

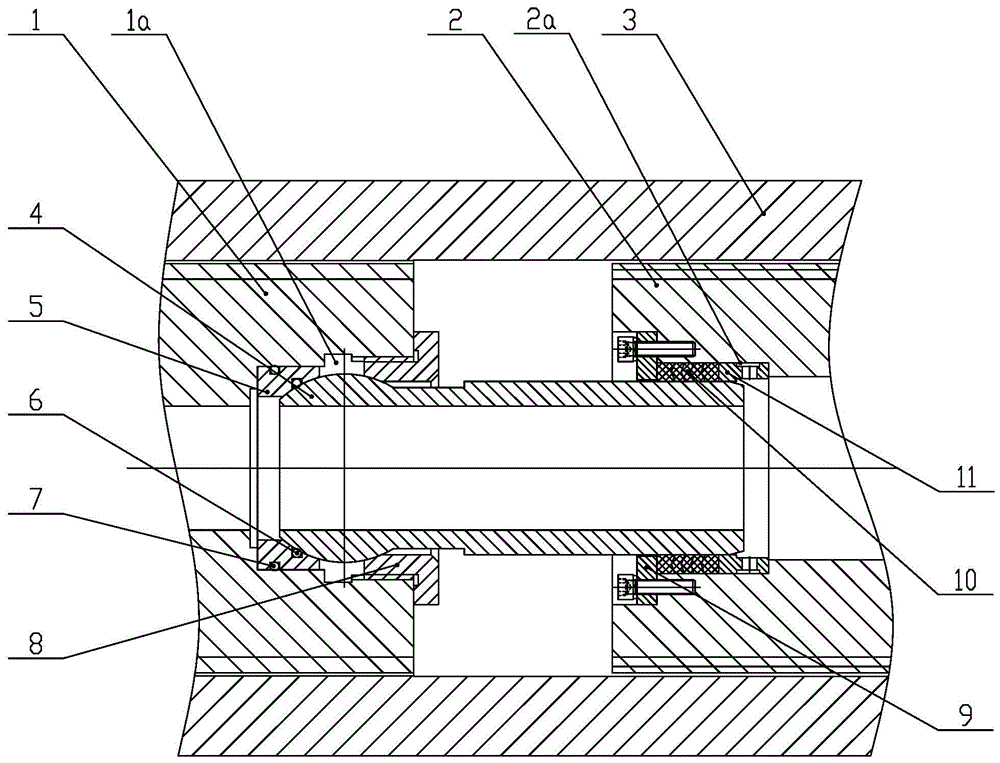

[0011] As shown in the figure: the floating device of the power head of the non-excavation pipelaying drilling rig in the embodiment is mainly composed of the main shaft of the power head 1, the floating nipple 2, the spline sleeve 3, the spherical water shaft 4, the wear ring 5, the first O Type sealing ring 6, the second O-ring 7, gland 8, baffle 9, water seal 10 and liner 11.

[0012] Such as figure 1 As shown, the main shaft 1 of the power head and the floating sub-joint 2 are connected through the spline sleeve 3. Since the floating sub-joint 2 can move axially in the spline sleeve 3 as required, the floating sub-joint 2 and the spline sleeve 3 adopt clearance fit; the inner hole of the main shaft 1 of the power head and the inner hole of the floating nipple 2 are sealed and connected by a hollow spherical water shaft 4; the first end of the spherical wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com