Diagnostic method for rebuilding three-dimensional geometric profile of knocking flame surface

A technology of three-dimensional geometry and diagnostic methods, applied in 3D modeling, image data processing, instruments, etc., can solve problems such as binocular stereo vision system synchronization, and achieve the effect of avoiding the need for synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

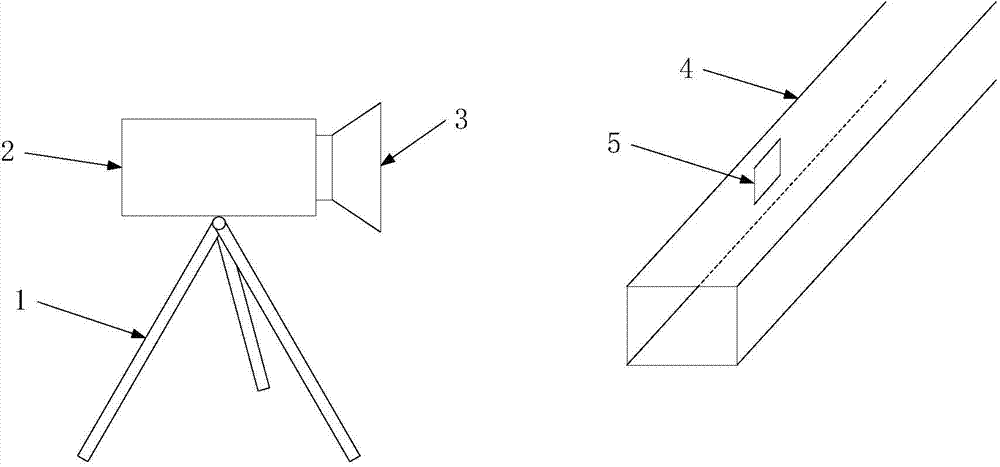

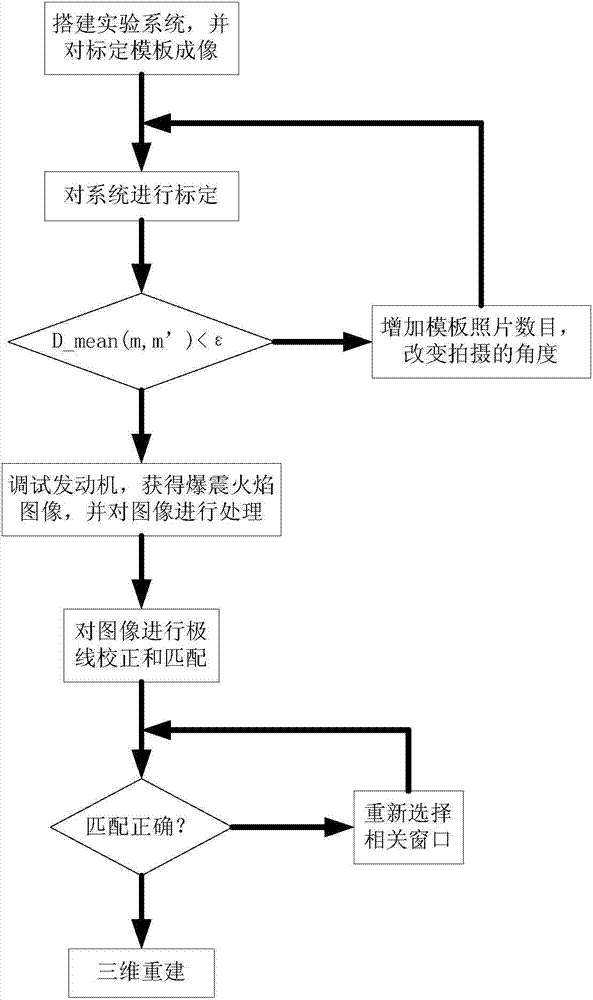

[0025] refer to Figure 1-2 . The specific steps of the diagnostic method for reconstructing the three-dimensional geometric shape of the detonation flame surface in the present invention are as follows:

[0026] Step 1: Build the experimental system. Refer to attached figure 1 In the figure, the high-speed camera 2 is placed on the tripod 1, and a four-mirror binocular mirror splitter 3 is added in front of the high-speed camera 2 to form a high-speed binocular stereoscopic vision system. The system is placed in front of the observation window 5 of the detonation tube 4. location. It is best to place the system so that the observation window can form two clear images in the camera and the image fills the entire view. According to experience, the system is about one meter away from the detonation tube observation window. After adjusting parameters such as aperture, focal length and shutter, keep the whole system still.

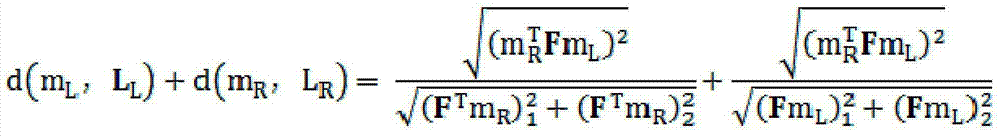

[0027] Step 2: Calibration of the system. The cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com