Electric spindle with cutting process monitoring system

A monitoring system and cutting processing technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve problems such as interference and insecurity, achieve high temperature and friction resistance, good electrical conduction effect, and reduce electric sparks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

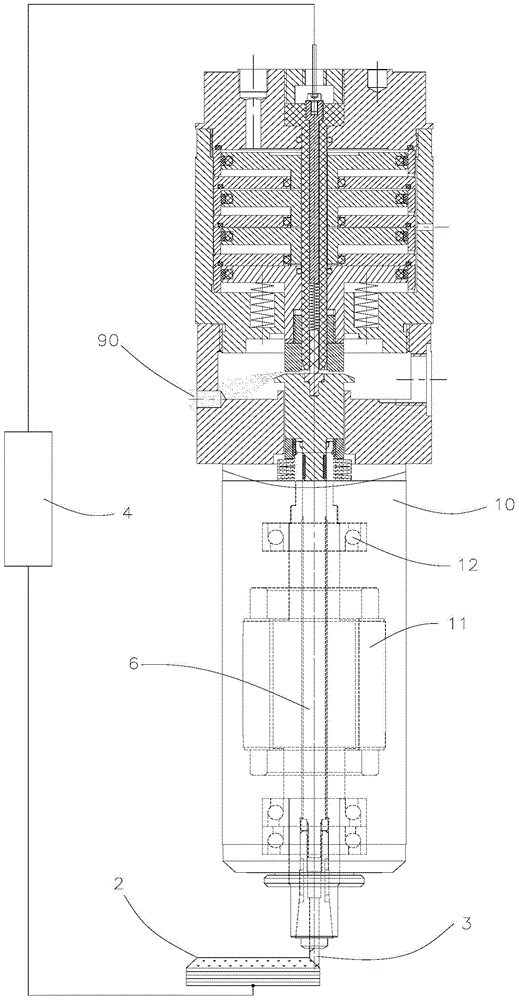

[0028] Electric spindle with cutting processing monitoring system, including: machine body 10, shaft core 6, intelligent monitoring system 4, carbon rod 84, slip ring 71, pull rod 70, tool 3, workpiece 2;

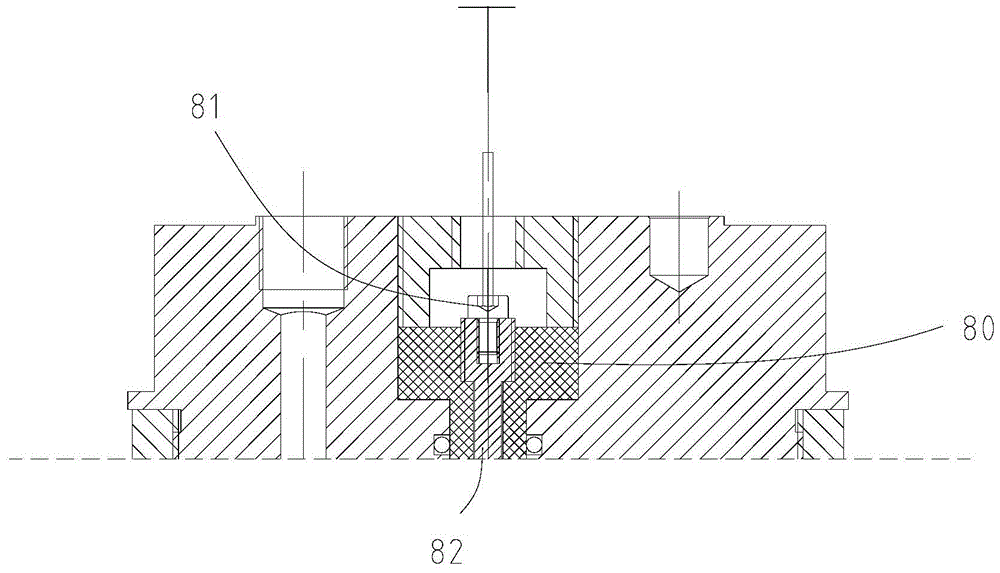

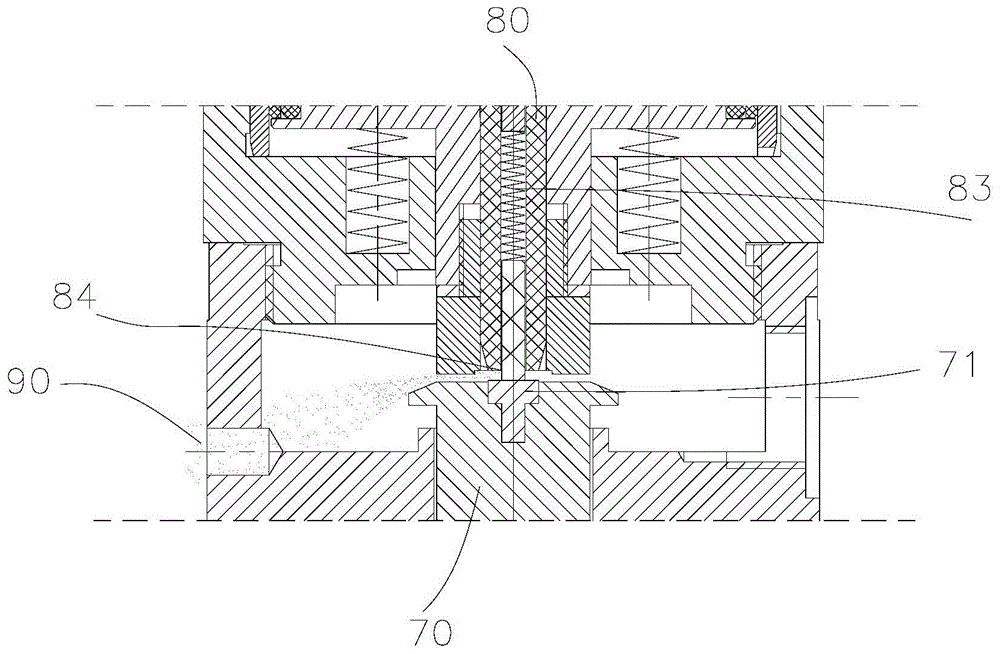

[0029] Such as figure 1 , Figure 4 As shown, the shaft core 6 is passed through the inside of the body 10, and is pivotally matched with the body 10 through the ceramic ball bearing 12; The slip ring 71 is assembled on the top of the pull rod 70 located at the upper end of the shaft core 6, and the slip ring 71 has an end face which is in contact with the lower end of the carbon rod 84 and is electrically conductive; the pull rod 70 is passed through the shaft core 6 and can rotate synchronously with the shaft core 6; the shaft core 6 is driven by a three-phase AC asynchronous motor 11; the tool 3 is fixed on the lower end of the lower shaft core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com