Actuator consisting of two magnetic bearing motors

A bearing motor, magnetic bearing technology, applied in the direction of bearings, shafts and bearings, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

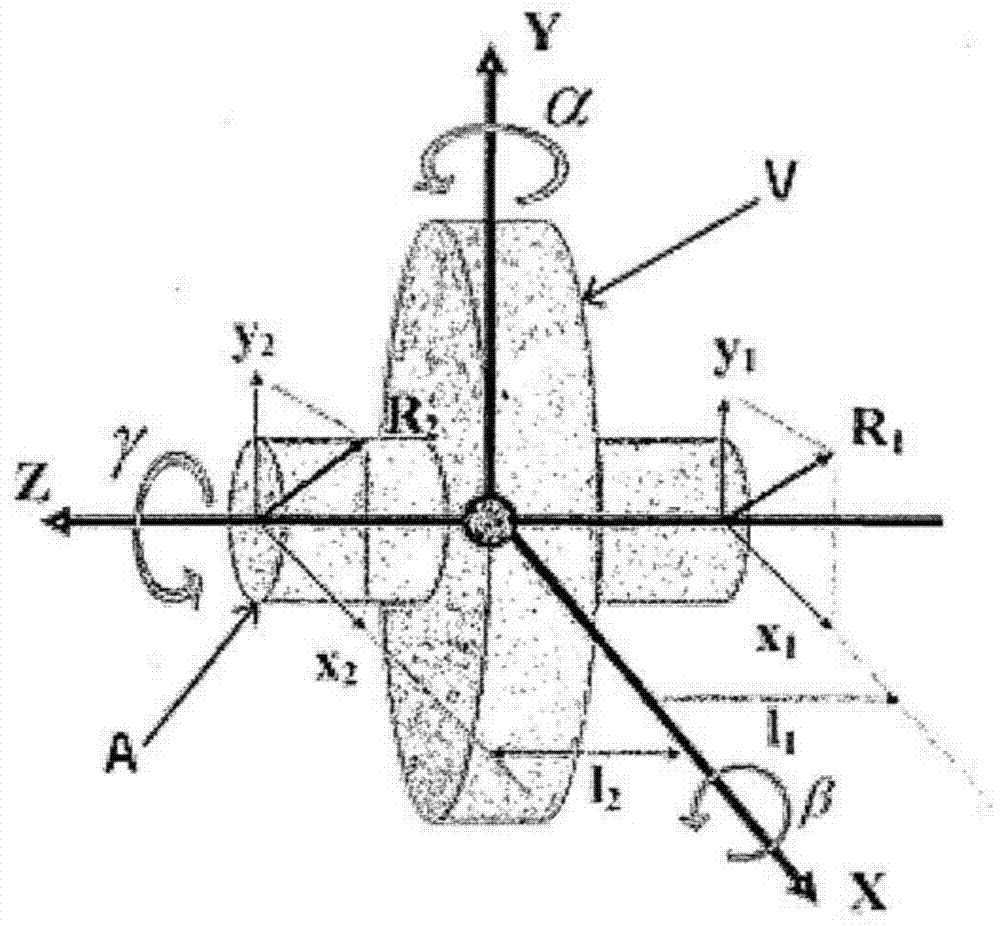

[0043] figure 1 Shown is a rotating element V, which can be a flywheel, and its shaft A. This figure refers to the rotation to show the possible degrees of freedom of the element V.

[0044] Assuming that this rotating element V is completely free, its motion in space can be described by a combination of three translations and three rotations relative to an orthogonal reference frame in terms of The axis Z of the extension of the axis of the rotating shaft member A, the axis Y contained in the plane of said element V and the axis X perpendicular to the first axis Z and the second axis Y are shown.

[0045] The three rotational degrees of freedom are rotation α around axis Y, rotation β around axis X, and rotation γ around axis Z. In the case that the flywheel V is intended to rotate about the axis Z, only the rotation γ is free, the rest are considered as parasitic rotations.

[0046] Still assuming that element V is completely free, there are three translational degrees of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com