Split-ring high precision unbalance vibration control system of magnetic suspension reaction flywheel

A reactive flywheel, vibration control technology, applied in general control systems, control/regulation systems, automatic control, etc., can solve problems such as unbalanced vibration control, and achieve the effect of simple and easy-to-implement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

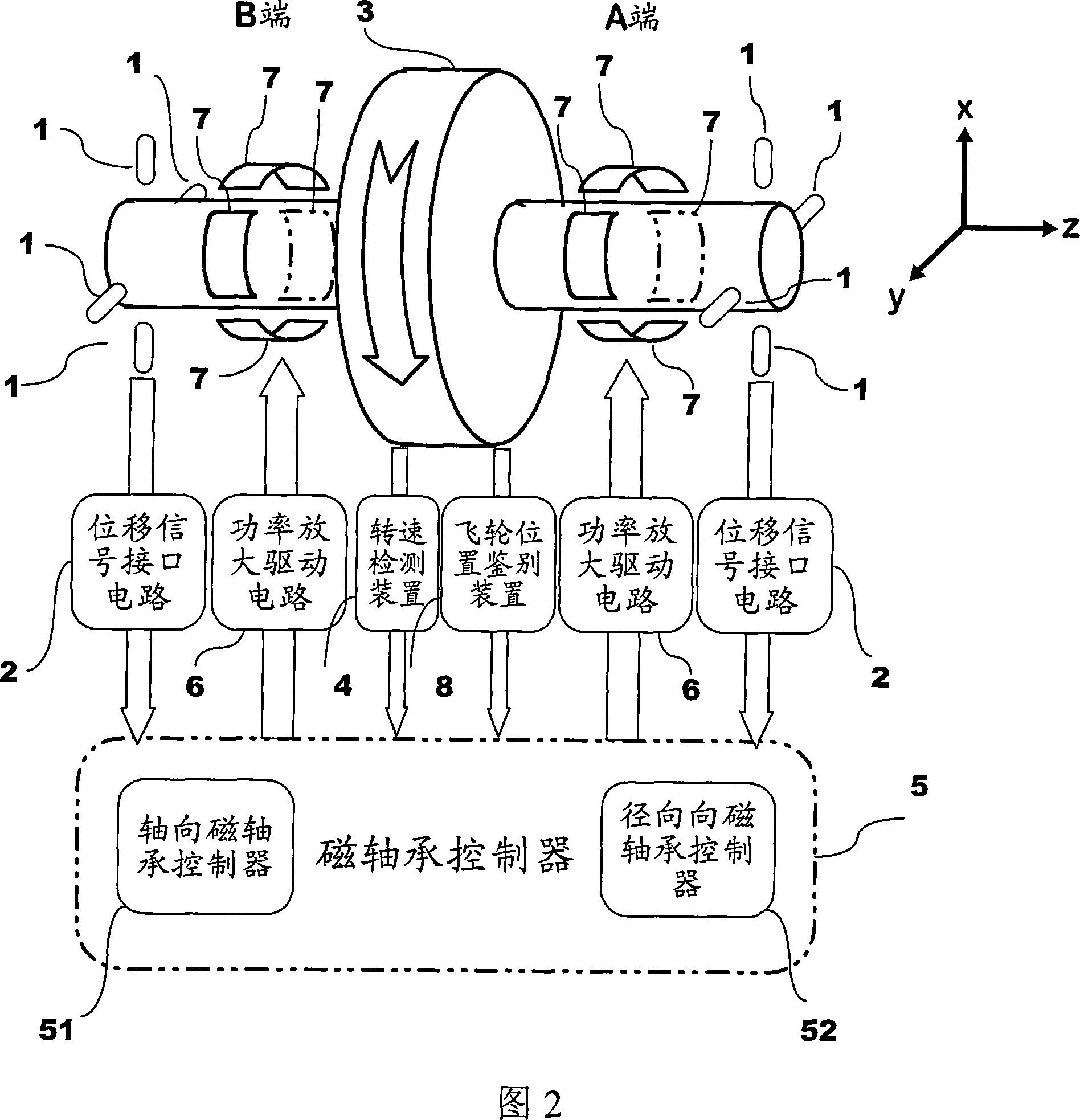

[0021] As shown in Figure 2, the magnetic levitation reaction flywheel open-loop high-precision unbalanced vibration control system wheel used in this embodiment includes a displacement sensor 1, a displacement signal interface circuit 2, a rotational speed detection device 4, a magnetic bearing controller 5, and a magnetic bearing power amplifier Drive circuit 6 and flywheel position discrimination device 8 . The displacement signal interface circuit 2 is used for zeroing the displacement signal detected by the magnetic levitation reaction flywheel rotor displacement sensor 1, and filtering the high-frequency noise; Digital quantity or voltage quantity, according to the magnetic bearing controller 5 input interface types used to decide); The magnetic bearing power amplification drive circuit 6 is used to convert the output control signal of the magnetic bearing controller 5 into the magnetic bearing coil 7 for driving the magnetic levitation reaction flywheel Control the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com