Rim with high-strength spoke weave

A high-strength, spoke technology, applied in spoked wheels, wheels, transportation and packaging, etc., can solve problems such as poor compressive strength, improved rim wind resistance, and rim deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

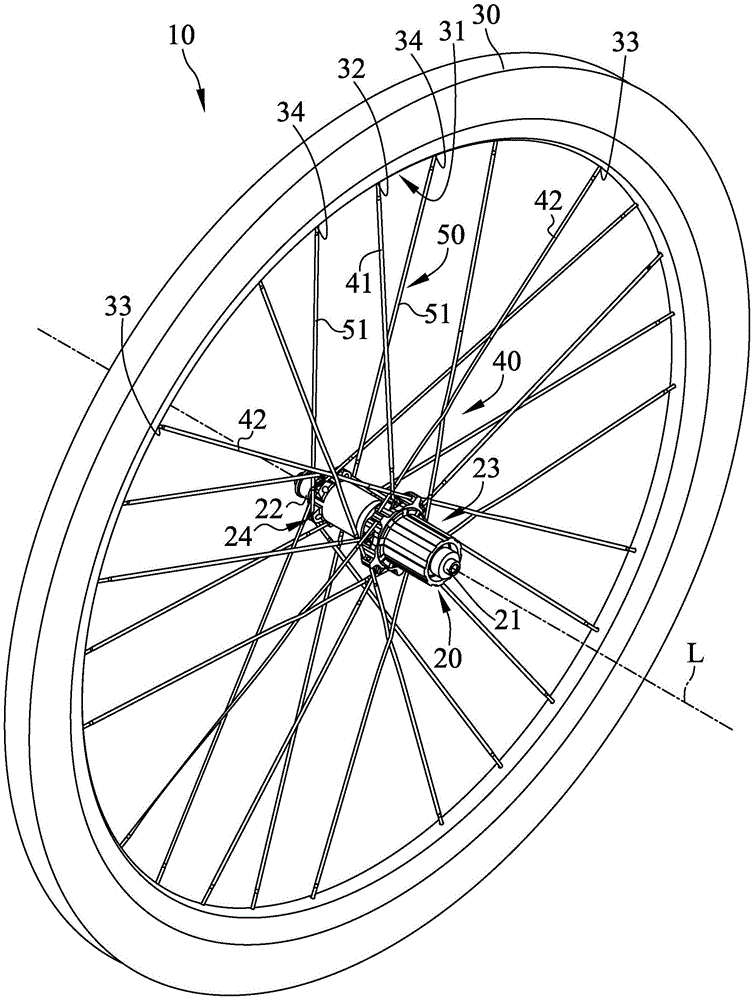

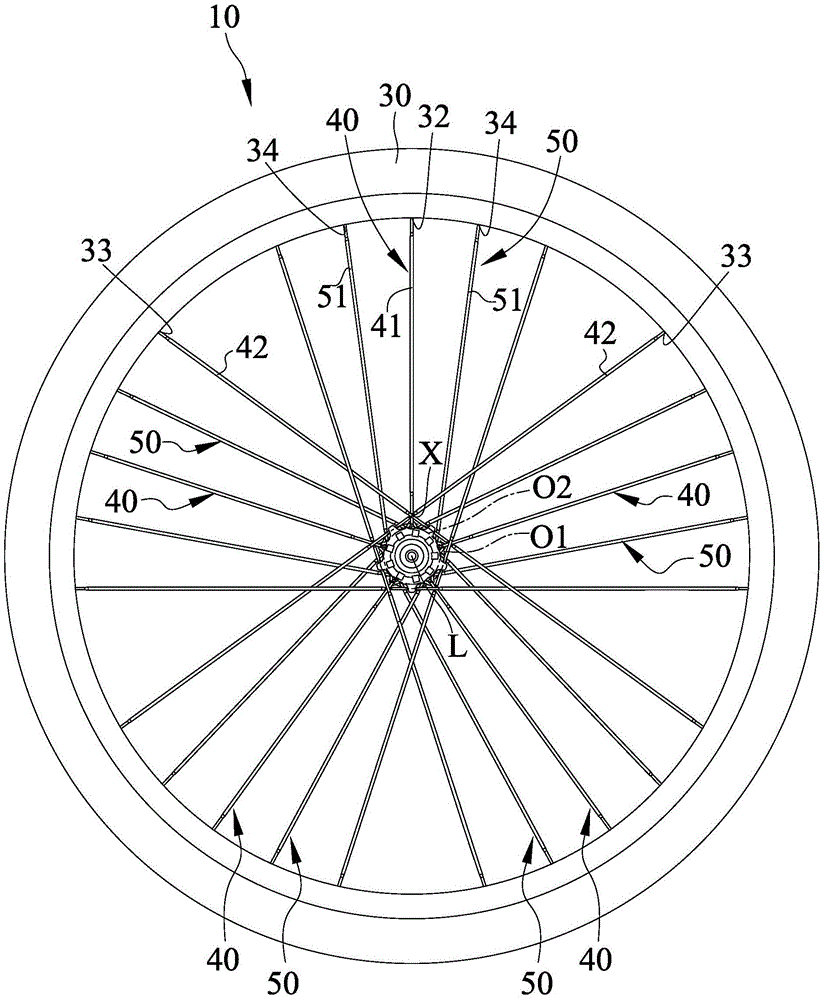

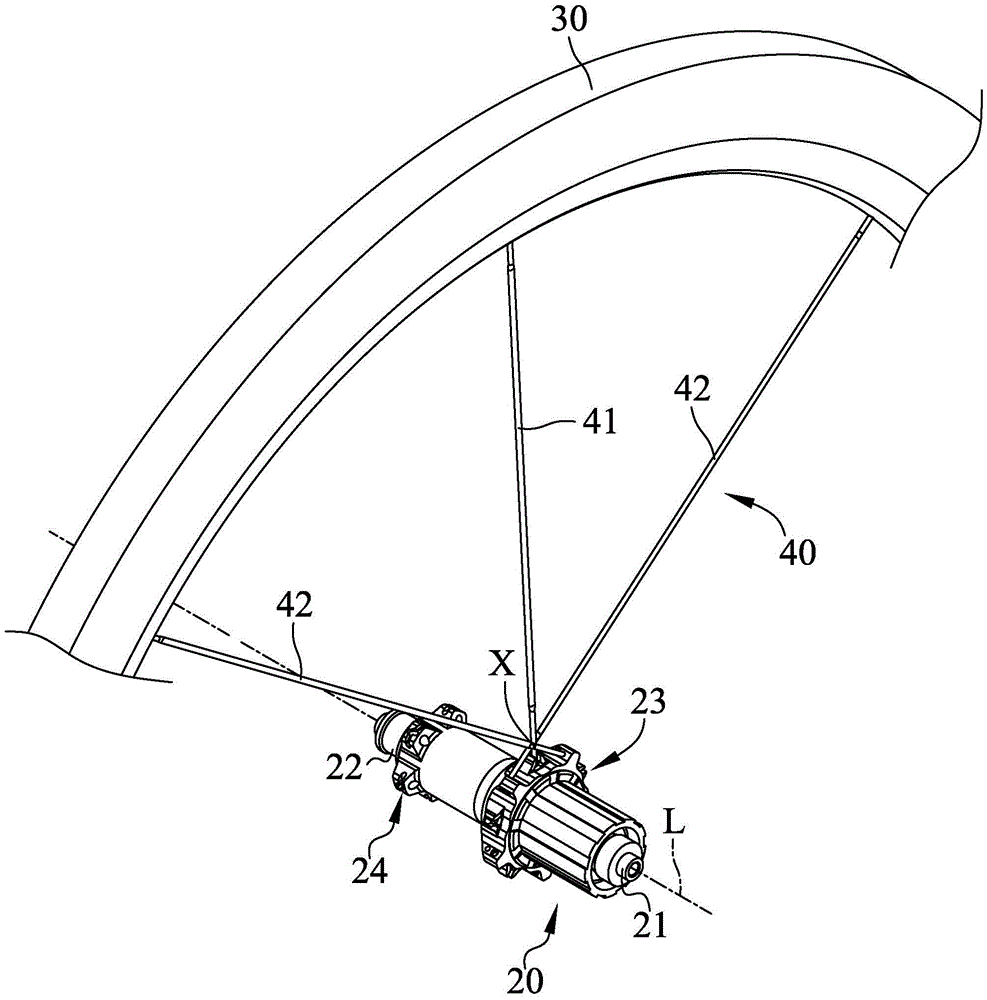

[0017] refer to figure 1 and figure 2 Shown is the three-dimensional appearance view and the front view of the first embodiment of the rim with high-strength spoke weaving method of the present invention. The rim 10 of the present invention includes a hub 20, a wheel frame 30 and at least three first spoke groups 40; wherein:

[0018] The hub 20 includes a first end 21 and a second end 22 . The hub 20 also has a virtual shaft L passing through the first end 21 and the second end 22 of the hub 20 . The hub 20 is formed with a first connecting portion 23 located at the first end 21 , and the hub 20 is formed with a second connecting portion 24 located at the second end 22 . The first connecting portion 23 has a first imaginary circle O1, the second connecting portion 24 has a second imaginary circle O2, and both the first imaginary circle O1 and the second imaginary circle O2 have the virtual axis L as the axis. , and the diameter of the second virtual circle O2 is smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com