Assembling box

A box and seat technology, which is applied in the direction of thin plate connection, connection member, engine frame, etc., can solve the problem that the connection method is not suitable for on-site assembly of large-sized box plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

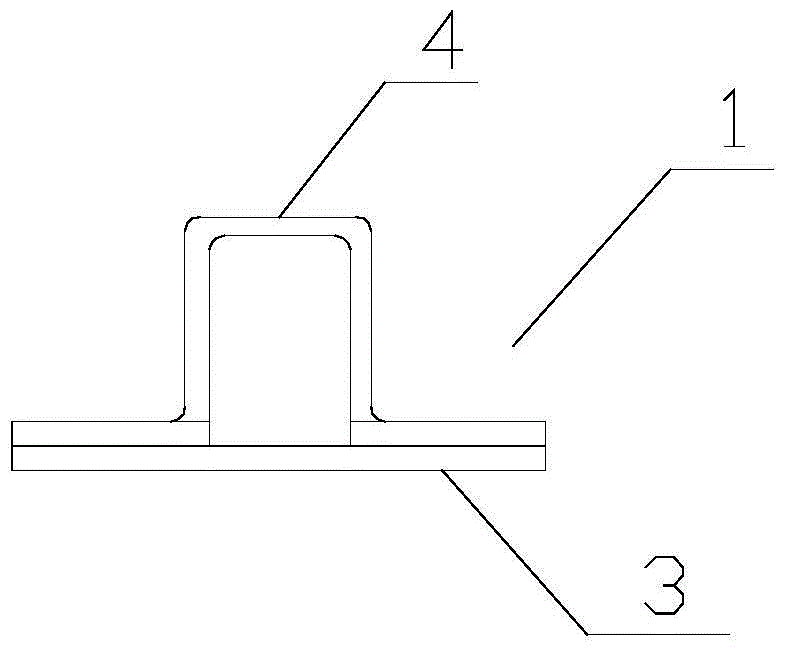

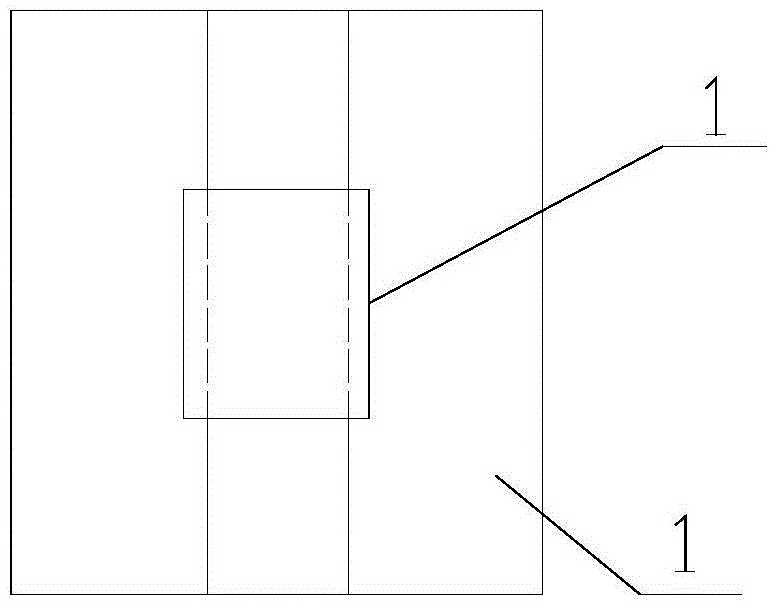

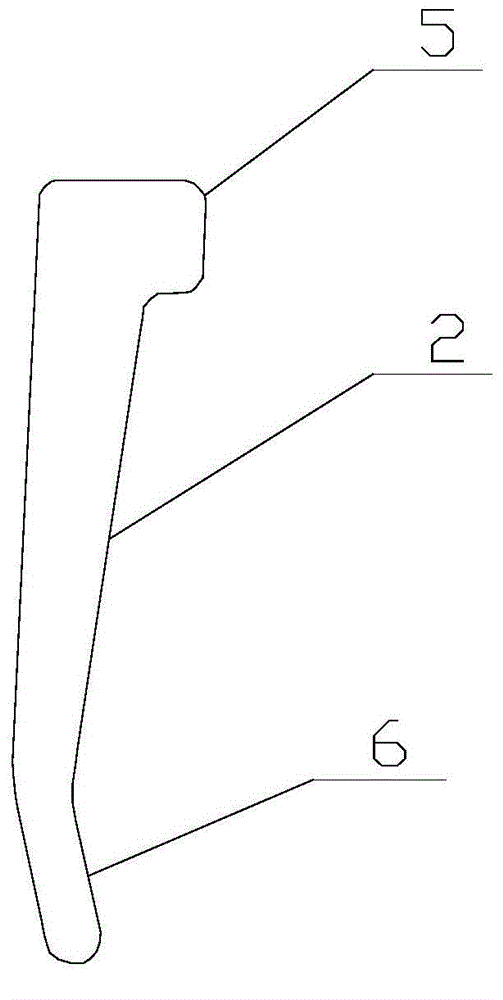

[0013] Such as Figure 1 to Figure 4 The assembled box of the present invention shown includes: a box plate 7, a buckle seat 1 and a pin 2. The box plate 7 is provided with a folded edge, and a preset hole 8 is provided on the folded edge. Two adjacent box body plates 7 The preset holes 8 are aligned; the buckle seat 1 is provided with a seat body 3 and a buckle ring 4. The buckle ring 4 is located in the middle of the seat body 3 and protrudes from the seat body 3. The size of the buckle ring 4 matches the preset hole 8. The seat 1 is inserted into the preset hole 8 of the box body through the buckle 4 and a part of it protrudes.

[0014] The plug 2 has a wedge shape, which is inserted into the protruding part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com