A pcba inspection system based on machine vision

A detection system and machine vision technology, applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of high error rate, low efficiency, and high labor cost, and achieve the effect of reducing labor cost, reducing error rate, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

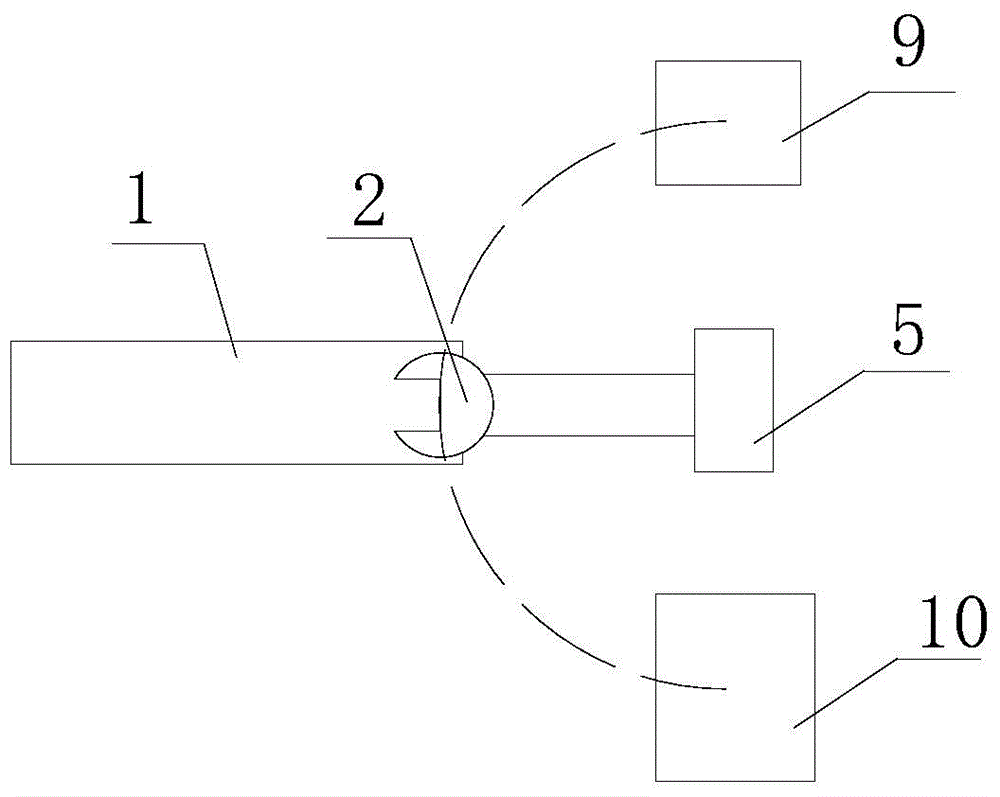

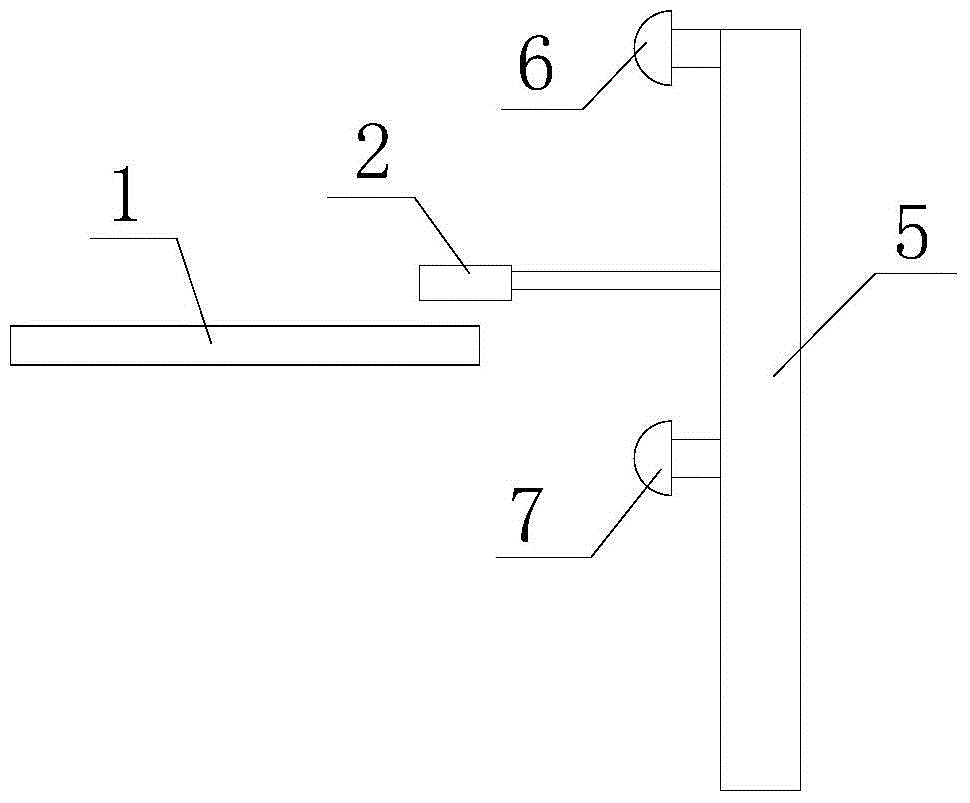

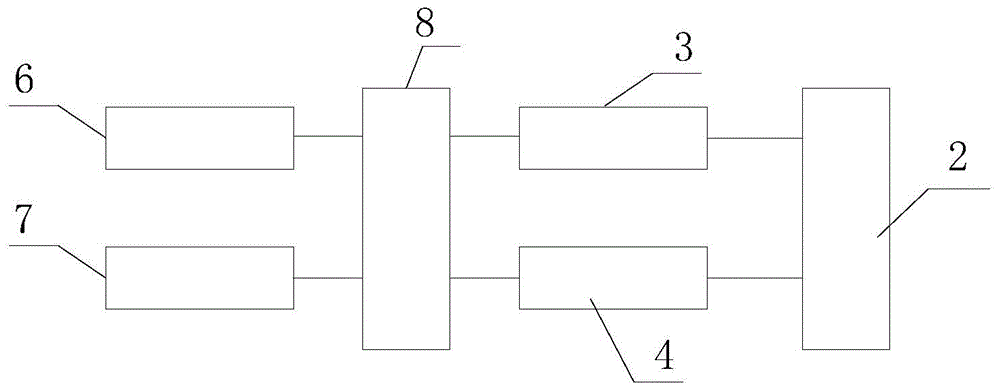

[0024] refer to figure 1 , figure 2 , image 3 , a PCBA inspection system based on machine vision proposed by the present invention includes: a feeding channel 1, a clamping mechanism 2, a first driving mechanism 3, a second driving mechanism 4, a support frame 5, a first camera device 6, a second Camera device 7 , control module 8 , first unloading mechanism 9 and second unloading mechanism 10 .

[0025] The feeding channel 1 is used to transport the PCBA to be detected.

[0026] The clamping mechanism 2 is rotatably installed on the support frame 5, the first unloading mechanism 9 and the second unloading mechanism 10 are all located on the rotation path of the clamping mechanism 2, the first unloading mechanism 9 is used for unloading qualified products, The second unloading mechanism 10 is used for unconforming product unloading.

[0027] The clamping mechanism 2 has three position states. In the first position state, the clamping mechanism 2 is connected to the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com