Cable connector

A technology of cable connectors and cables, which is applied in the direction of connection, insulation cables, cables, etc., can solve the problems of loose connection between cables and inner core terminals, poor reliability of cable connectors, poor sealing of bellows and connector connections, etc. Achieve the effects of avoiding poor contact, improving reliability and sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

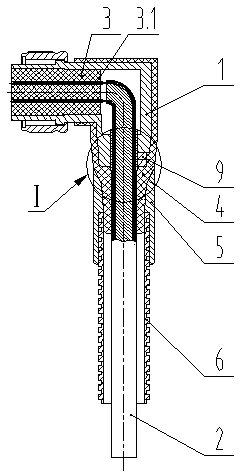

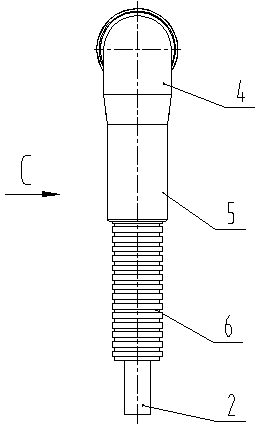

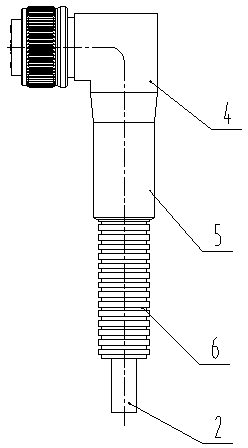

[0022] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

[0023] The cable connector shown in the accompanying drawings is set at one end of the cable 2 and includes a housing 1, an inner core 3, a bellows 6, an outer jacket 5, a sheath 4, and a cable tightening structure 9; the inner core 3 is set on the housing 1 In the hole; the cable 2 extends from one end of the shell 1 into the hole of the shell 1, and connects with the terminal 3.1 in the inner core 3.

[0024] Carry out the first rubber coating on the outer wall of the shell 1 part where the cable 2 extends into the shell 1, and the outer wall of the cable 2 part outside the shell 1, forming an integral structure, wrapping and sealingly connecting the cable 2 into the shell 1 Part of the outer wall of the housing 1 at the place, the sheath 4 on the outer wall of the part of the cable 2 outside the housing 1 (in other embodiments, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com