A kind of production technology of film coating agent

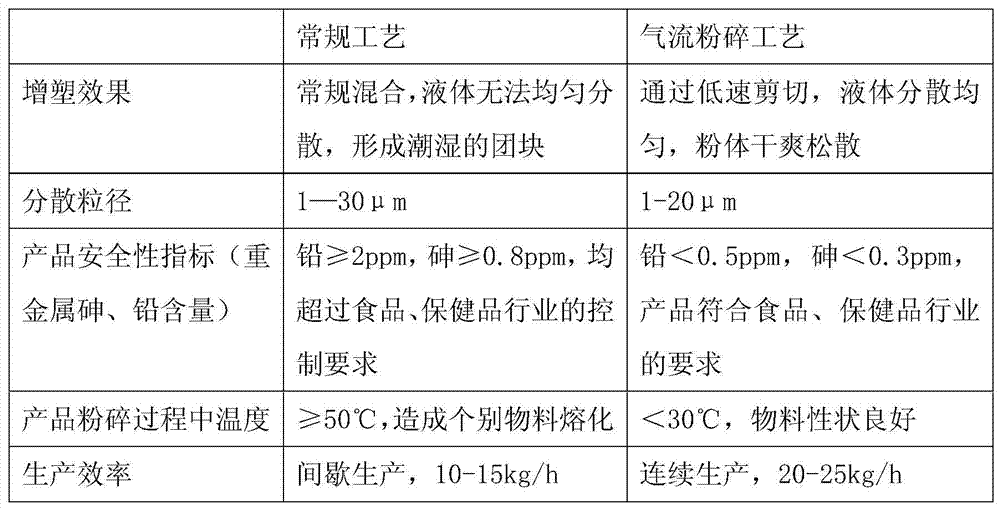

A technology of film coating agent and production process, which is applied in the field of preparation of drug coating materials, can solve the problems of high heavy metal content and uneven particle size, and achieve the effect of uniform particle size, small particle size and good plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

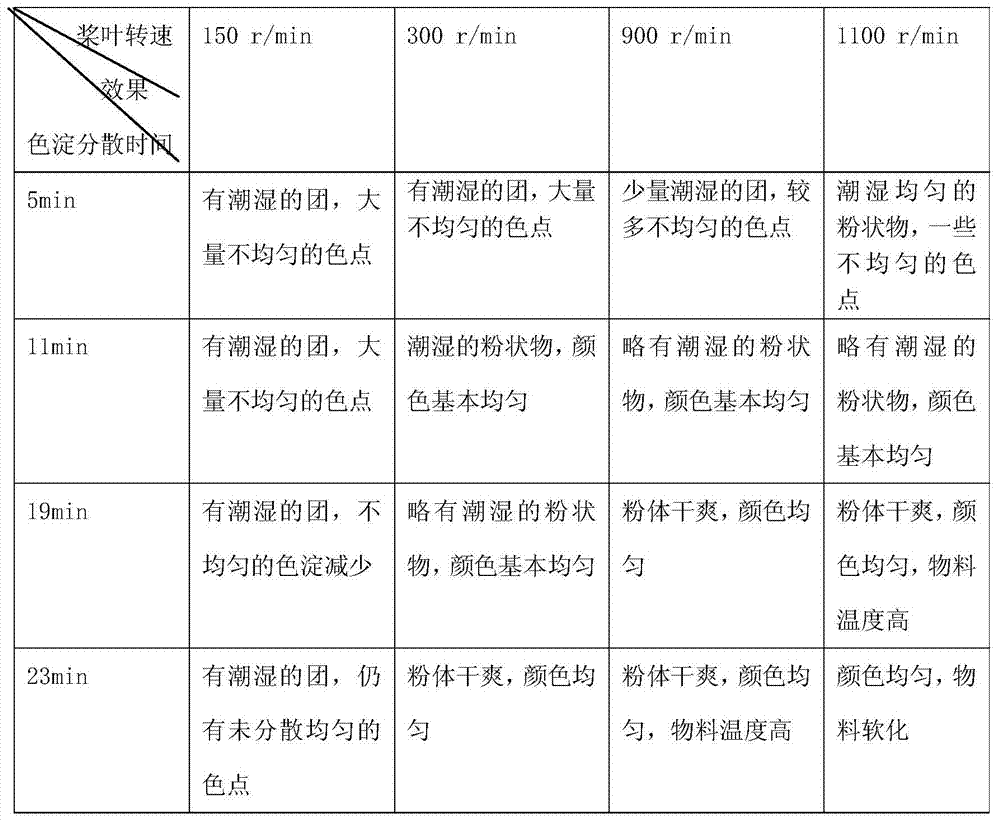

Method used

Image

Examples

Embodiment 1

[0058] 1. Add 850g of hydroxypropyl methylcellulose into the mixer, control the blade speed of the mixing equipment to 200 rpm, slowly add 60g of glycerin, and run the equipment for 6 minutes to achieve plasticization of the material.

[0059] 2. Put 90g of titanium dioxide into the mixer, control the blade rotation speed of the mixing equipment to 200 rpm, and mix the coated colorant for 10 minutes to form a mixture.

[0060] 3. The mixed material is put into the airflow mill, the compressed air pressure is 0.7MPa, the material is crushed by the airflow in the crushing chamber, and then discharged to obtain the finished coating agent with uniform color and particle size meeting the requirements.

Embodiment 2

[0062] 1. Add 610g of methylcellulose into the mixer, control the blade speed of the mixing equipment to 600 rpm, slowly add 160g castor oil, and run the equipment for 10.5 minutes to achieve plasticization of the material.

[0063] 2. Put 190g of titanium dioxide and 40g of sunset yellow lake into the mixer, control the blade rotation speed of the mixing equipment to 600 rpm, and mix the coated colorant for 15 minutes to form a mixture.

[0064] 3. The mixed material is put into the airflow mill, the compressed air pressure is 0.85MPa, the material is crushed by the airflow in the crushing chamber, and then discharged to obtain the finished coating agent with uniform color and particle size meeting the requirements.

Embodiment 3

[0066] 1. Add 300g of hydroxypropyl cellulose into the mixer, control the blade speed of the mixing equipment to 1000 rpm, slowly add 200g of triethyl citrate, and run the equipment for 15 minutes to achieve plasticization of the material.

[0067] 2. Put 150g of titanium dioxide and 350g of medicinal iron oxide into the mixer, control the rotation speed of the blades of the mixing equipment to 1000 rpm, and mix the coated colorant for 20 minutes to form a mixture.

[0068] 3. The mixed material is put into the airflow mill, the compressed air pressure is 1.0MPa, the material is crushed by the airflow in the crushing chamber, and then discharged to obtain the finished coating agent with uniform color and particle size meeting the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com