A corner core pulling method and device for mold casting

A core-pulling device and die-casting technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of mold space and rack space equipment and its cost waste, and achieve the effect of saving mold space and rack space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

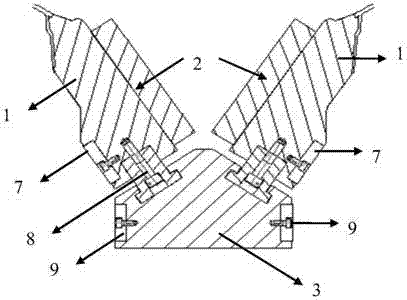

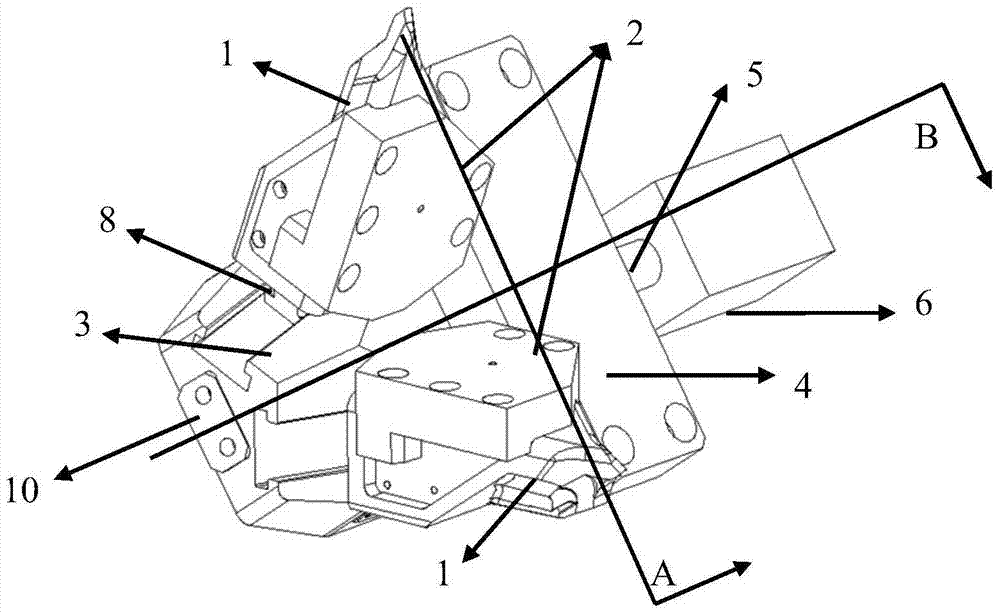

[0094] First, the corner core-pulling device for die casting of the present invention is obtained, and the corner core-pulling device for die casting comprises:

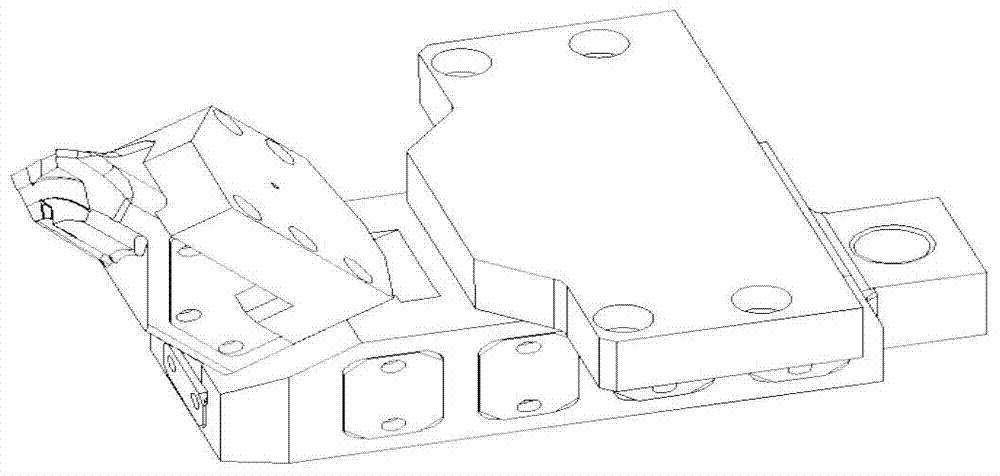

[0095] The core-pulling member 1 whose top is in contact with the molded part and performs core-pulling, the driving slider 3 that drives the core-pulling member to move, and the oil cylinder 6 provided at one end of the driving slider to provide power, and the driving slider is arranged on the core-pulling below the component,

[0096] The upper part of the driving slider 3 is formed with an inclined surface inclined downward on both sides in the running direction of the driving slider,

[0097] The inclined surface on both sides of the running direction of the driving slider is provided with a chute, and the bottom of the core pulling member is formed with a slider 8 that can be embedded with the chute and slide in the chute. The two inclined surfaces of the slide block form a variable height along the traveling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com