Supplementary volume equal volume displacement clamping device

A clamping device and volumetric technology, applied in presses, manufacturing tools, etc., can solve problems such as limited structural size ratio, long structural size, uneven force, etc., to avoid hidden dangers of fracture, short boosting time, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

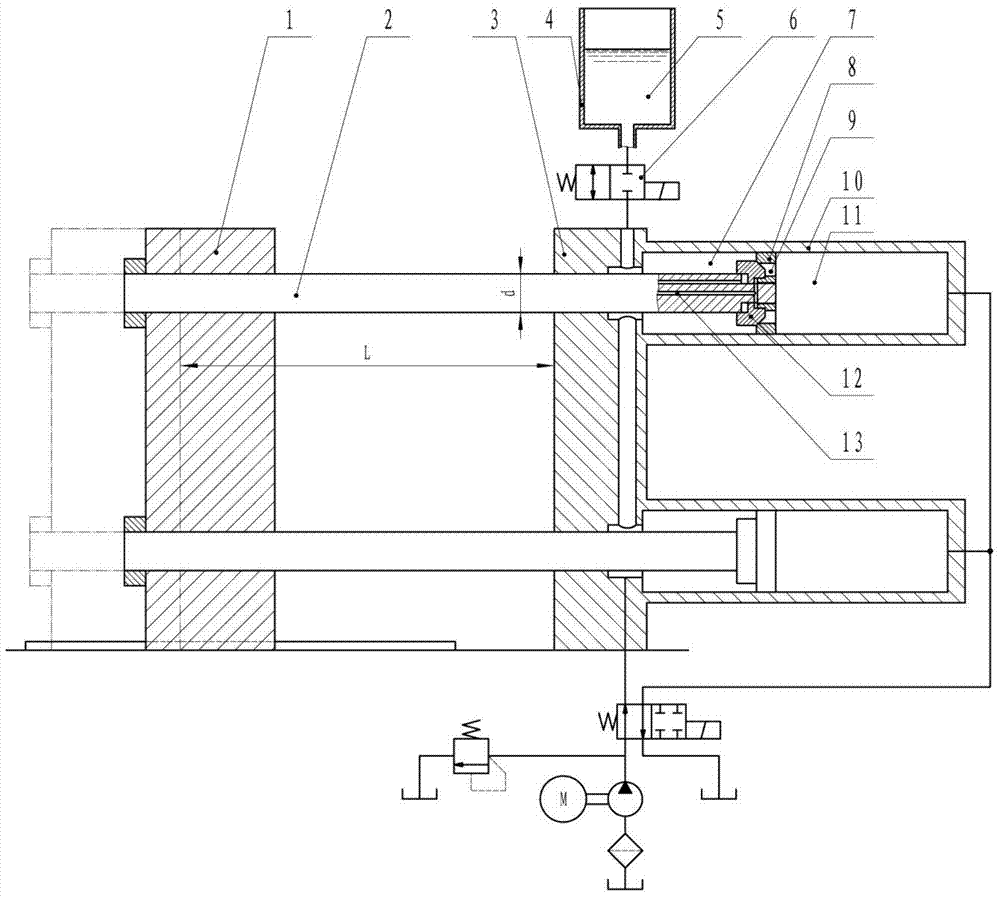

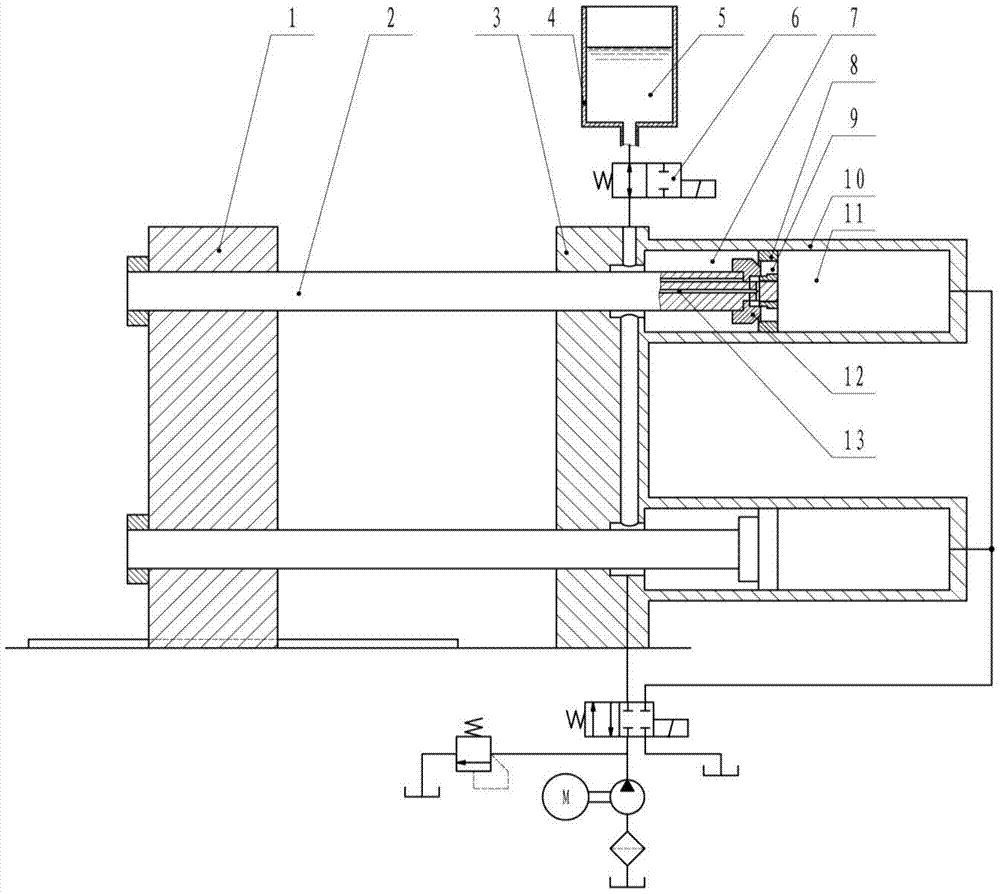

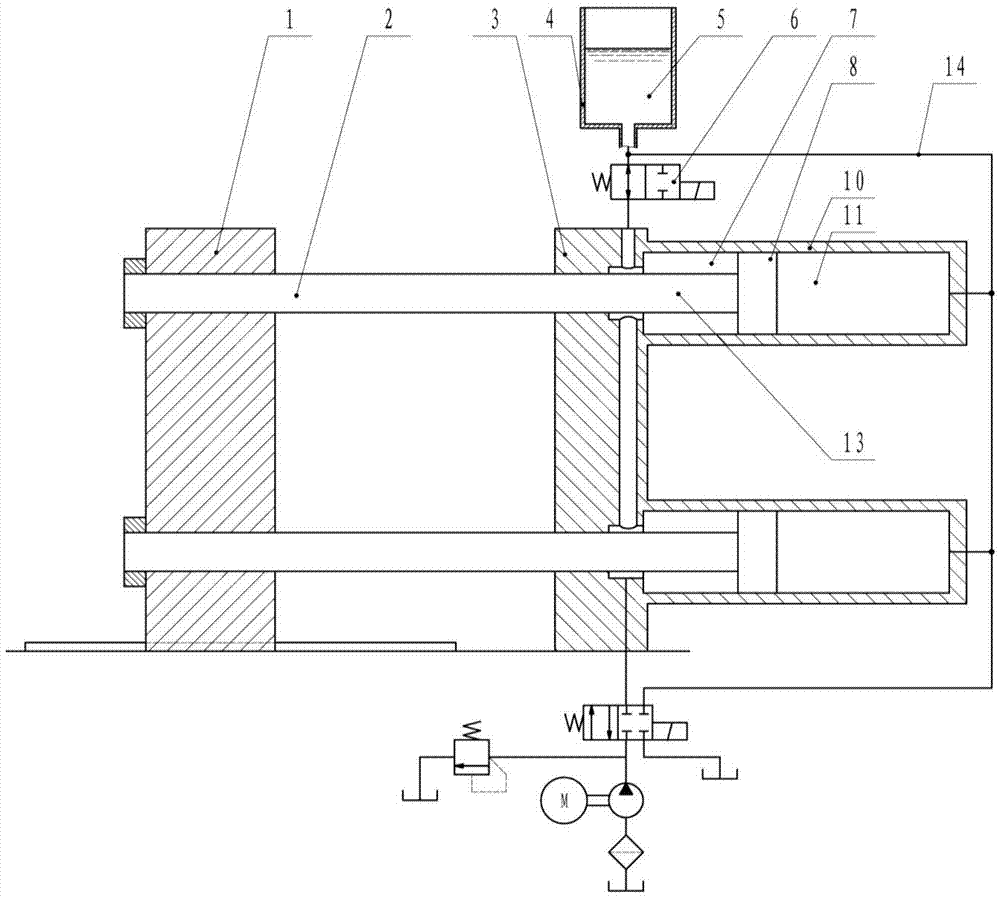

[0027] Such as Figure 1 ~ Figure 3As shown, the supplementary volume type equal-volume displacement mold clamping device of the present invention is composed of a movable platen 1, a fixed platen 3, a clamping cylinder, a supplementary cylinder 4 and a communication stop valve 6, and the clamping cylinder includes a cylinder body 10, a piston 8 and The piston rod 2 and the clamping cylinder are set on the fixed platen 3; the piston 8 is set in the cylinder body 10, and the cylinder body 10 is divided into a rod chamber 7 and a rodless chamber 11; one end of the piston rod 2 is connected with the piston 8, and the piston rod 2. The other end is connected with the movable template 1, and the piston rod 2 passes through the rod chamber 7 and the fixed template 3; the supplementary oil cylinder 4 is arranged on the upper part of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com