Windscreen wiper

A technology of wiper and wiper arm, which is applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc. It can solve the problems of difficult installation and the difficulty of aligning the hook part with the accessory seat, etc., and achieves the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

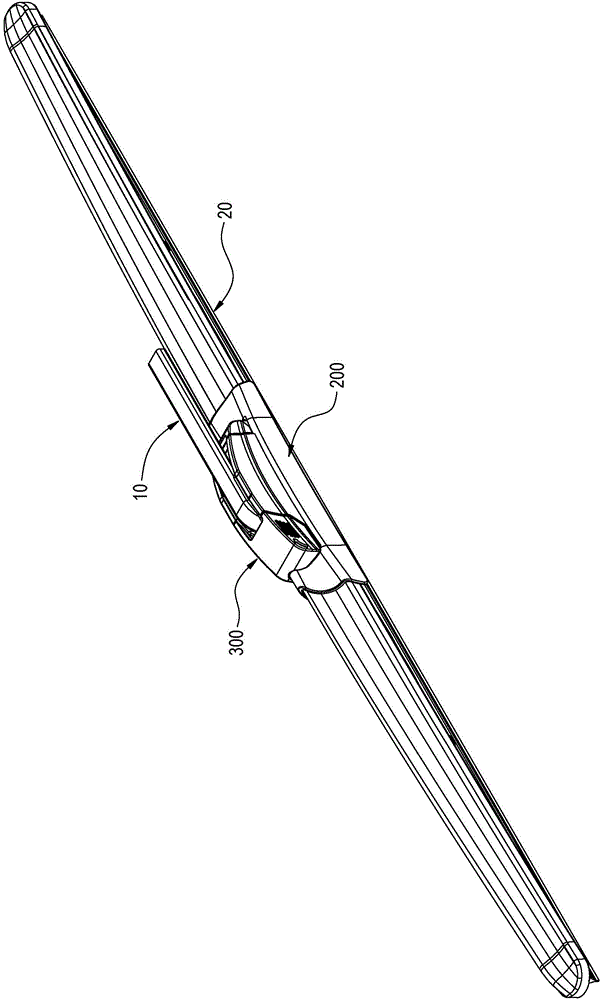

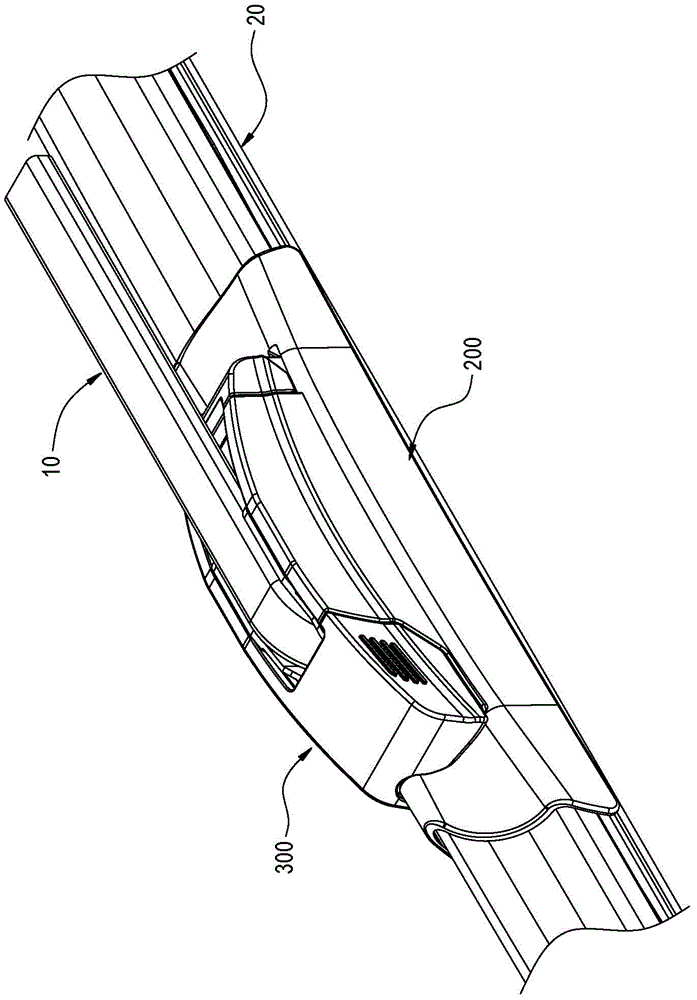

[0049] refer to figure 1 A preferred embodiment of the present invention provides a wiper device, which is used to pivotally connect one end of a wiper arm 10 to a wiper strip 20 so that the wiper strip 20 can pivot relative to the wiper arm 10 . Wherein the wiper arm 10 is a metal rod, and one end of the wiper arm 10 has a hook portion 11, the hook portion 11 is bent into a U shape; . In this embodiment, the wiper device of the present invention includes an accessory seat 100 , an outer casing 200 and a buckle cover 300 .

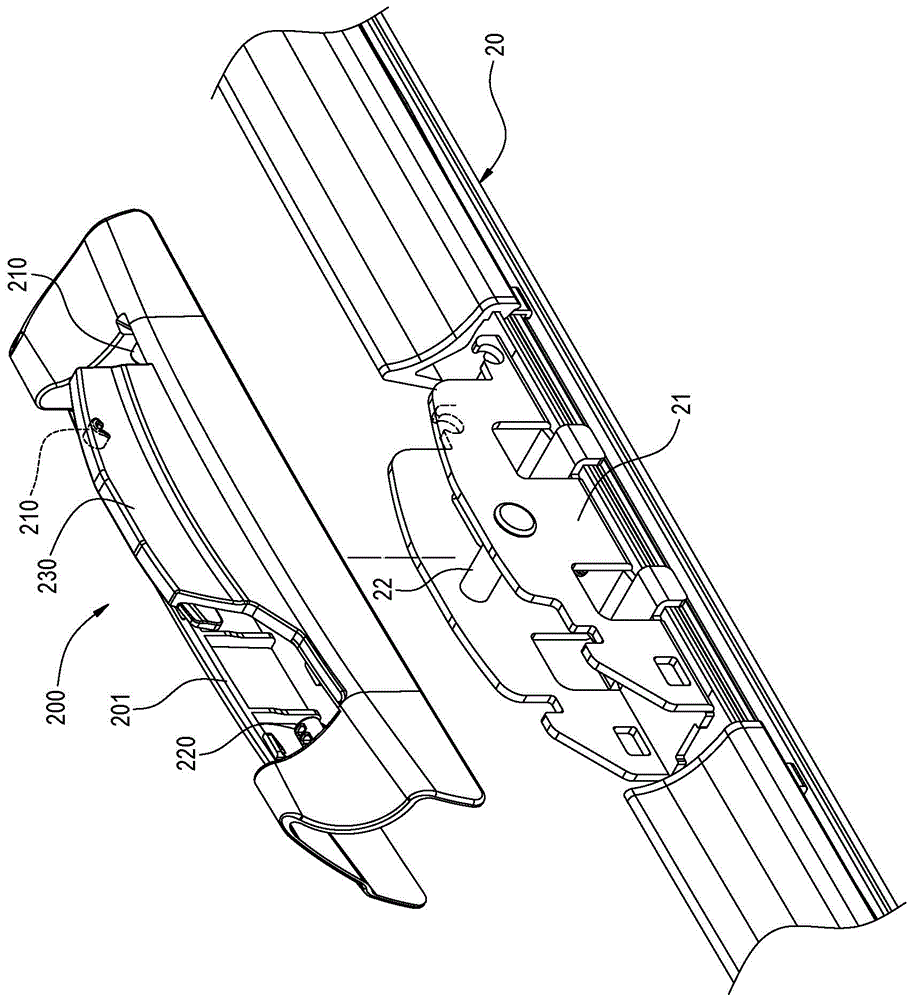

[0050] refer to Figure 2 to Figure 4 , in this example, the accessory seat 100 is generally in the shape of a long column. The accessory seat 100 has a main body 110, side plates 111, and side plates 112. Between the board 111 and the side board 112 . A pivot slot 120 is defined on one side of the body 110 . The pivot slot 120 is preferably connected between the side panel 111 and the side panel 112 and passes through the side panel 111 and the side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com