Vibratory conveying apparatus

A conveying device and vibrating technology, which is applied in the field of vibrating conveying devices, can solve problems such as insufficient performance, insufficient amplitude, and difficulty in adjusting the number of vibrations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

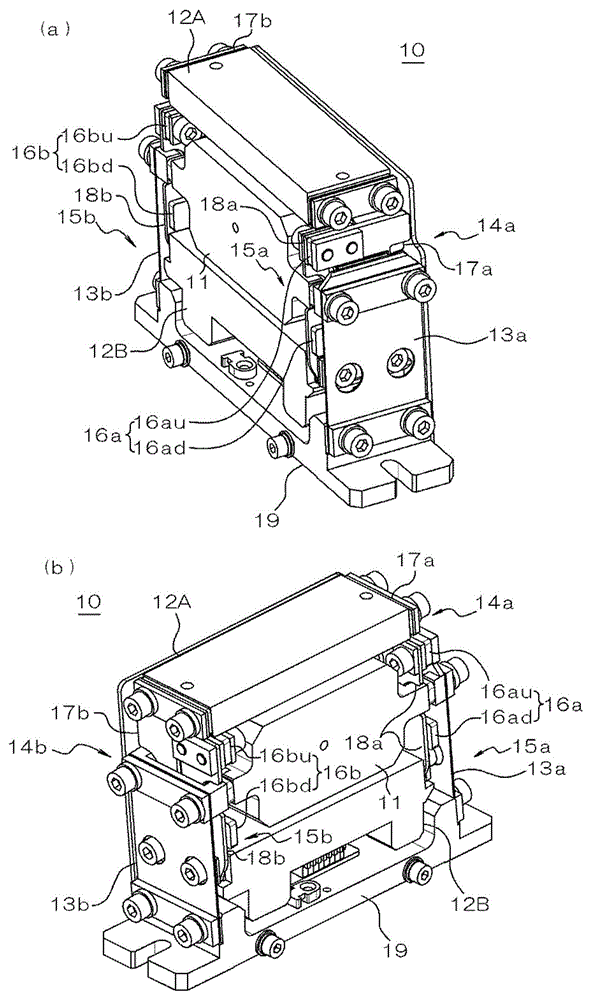

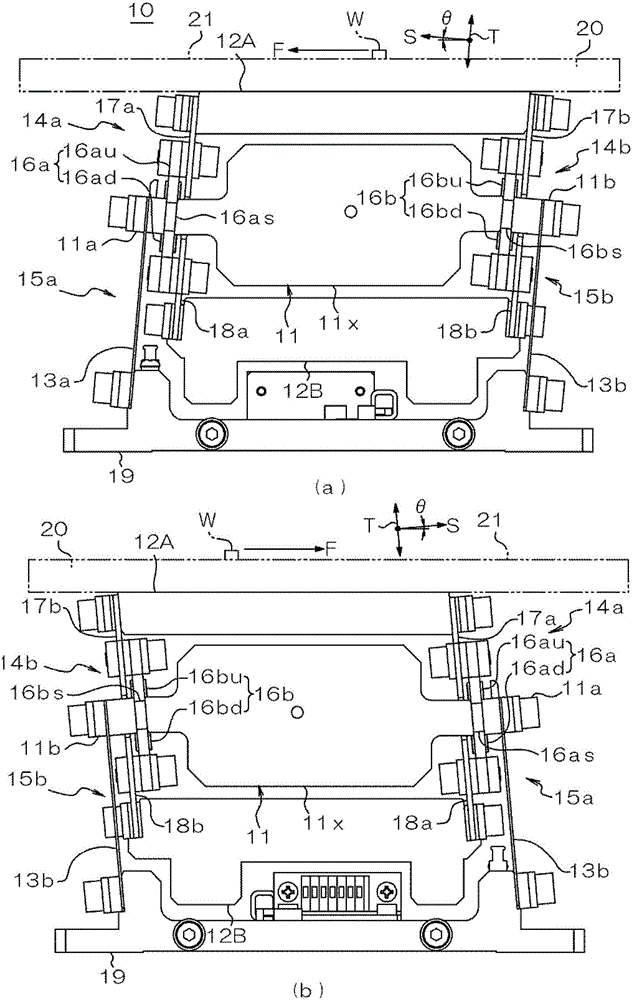

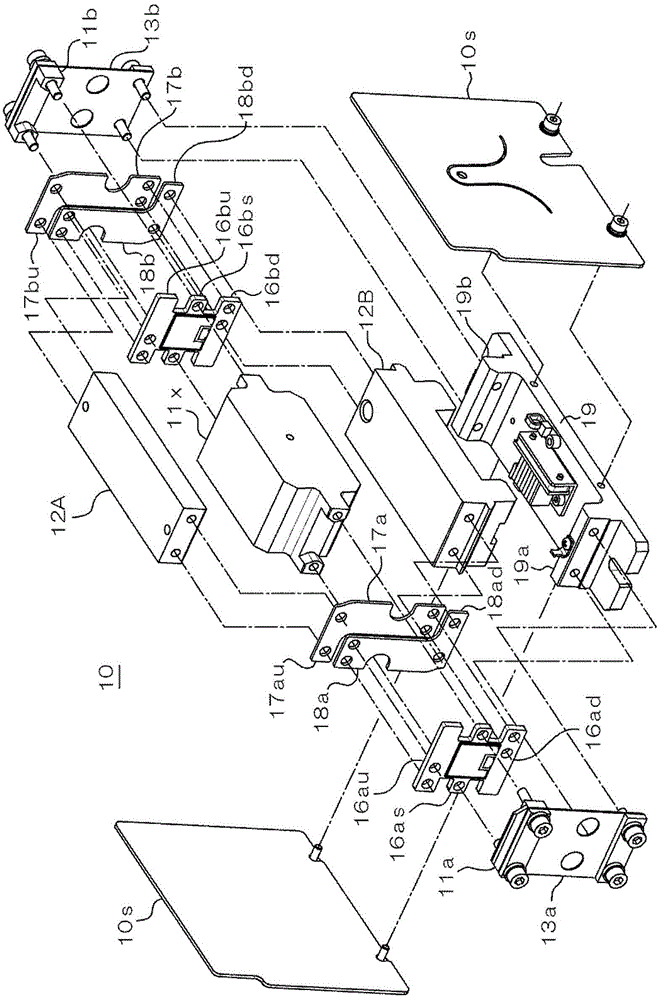

[0052] Next, embodiments of the present invention will be described in detail with reference to the drawings. Figure 1 ~ Figure 3 These are a perspective view, a side view, and an exploded perspective view showing the overall structure of the present embodiment, respectively. in addition, Figure 4 is the front view of the piezoelectric actuator, Figure 5 It is a front view showing the up and down amplifying springs connected to the upper mass body and the lower mass body.

[0053] The vibration conveying device 10 of the present embodiment includes a reference mass body 11 , an upper mass body 12A disposed above the reference mass body 11 , and a lower mass body 12B disposed below the reference mass body 11 . The reference mass body 11 is moving along the conveying direction F (refer to figure 2 ) in the conveying direction are respectively supported from below by plate-shaped anti-vibration springs 13a and 13b, wherein the plate-shaped anti-vibration springs 13a and 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com