Stamping and feeding device of high-grade steel

A feeding equipment and material clamping technology, applied in the field of workpiece processing, can solve the problems that the material cannot be accurately punched in the preset position, the material is prone to deflection, and the material is damaged, so as to improve the stability, reduce the path, and improve the success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

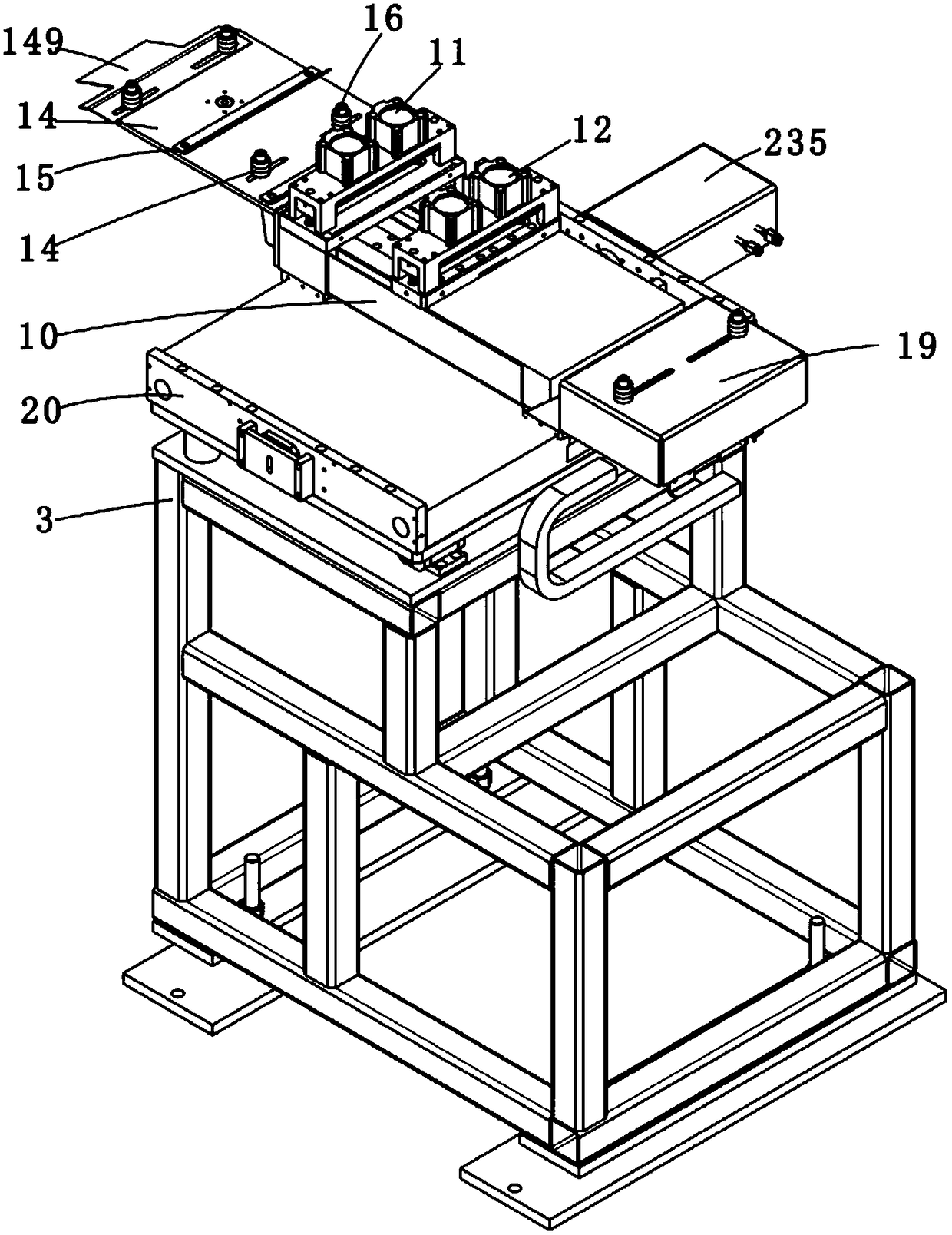

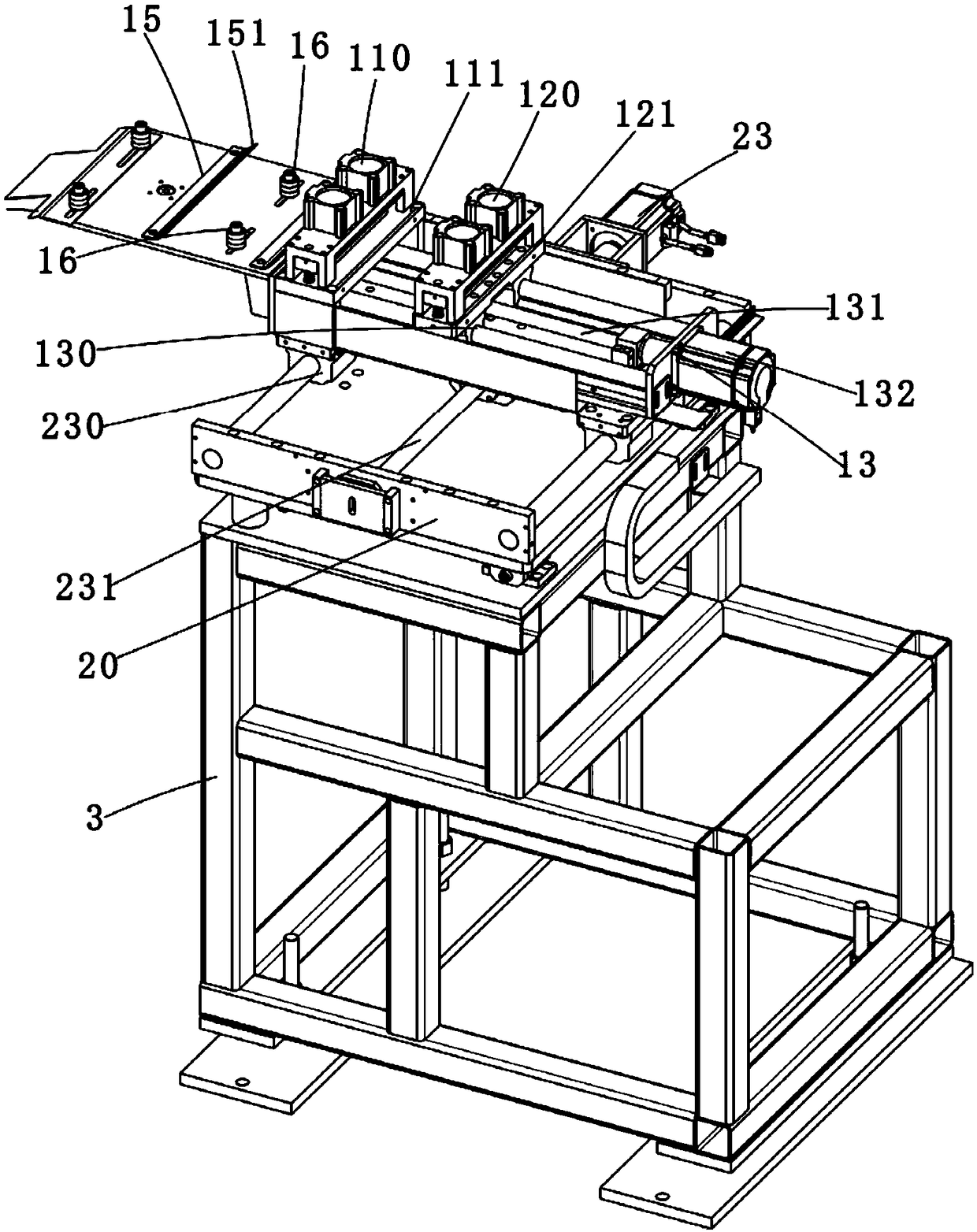

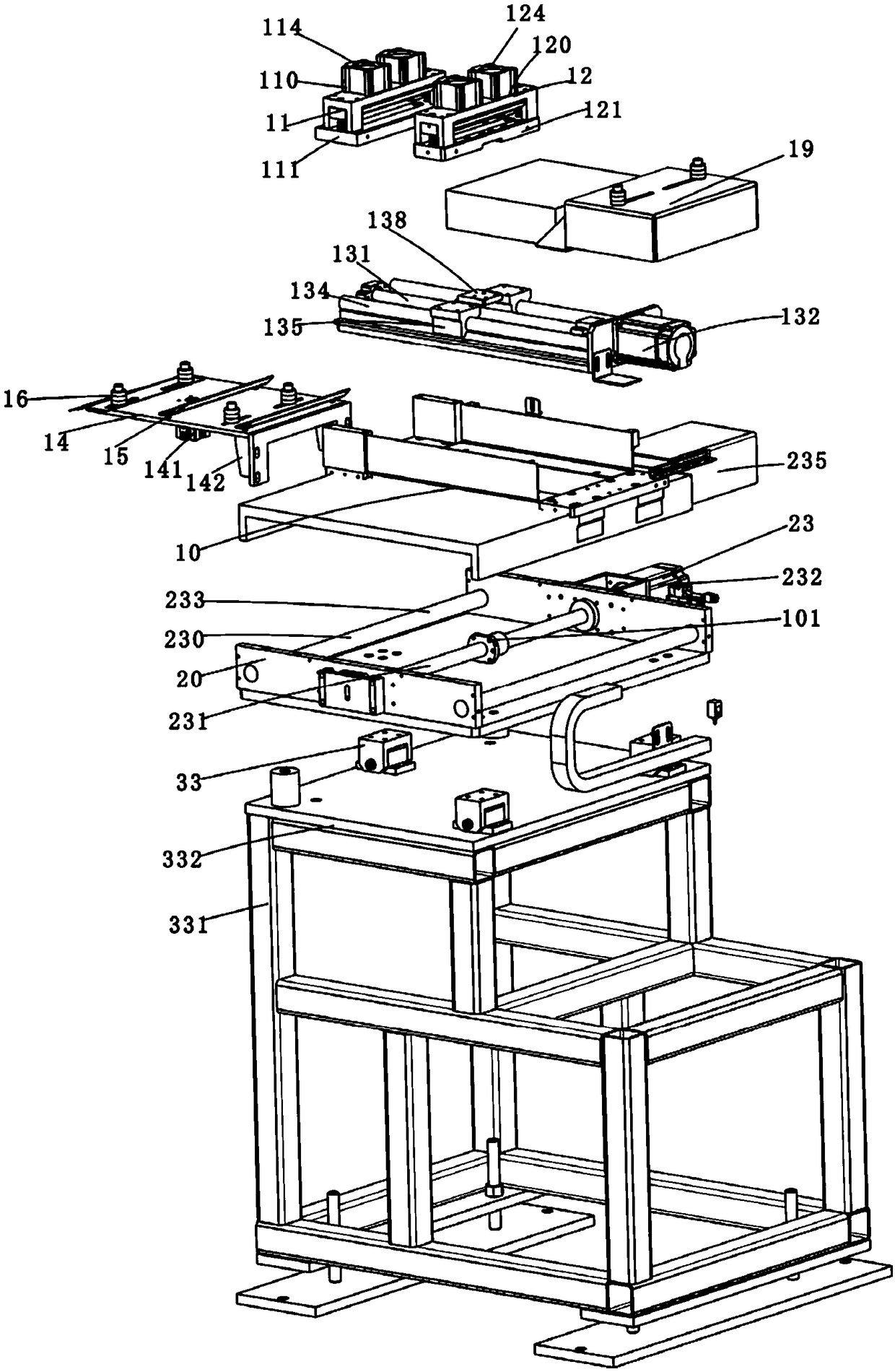

[0035] Such as Figure 1-14 As shown, a high-quality steel stamping feeding equipment includes a first frame body 10, a first clamping device 11, a second clamping device 12 and a first driving device 13, wherein the first clamping device 11 and the second The material clamping devices 12 are all arranged on the first frame body 10, and the first material clamping device 11 and the second material clamping device 12 cooperate with each other to feed materials when feeding. The specific cooperation is: the initial material is manually or otherwise When the equipment is fed into the entire side feeder, the second clamping device 12 first clamps the material, and then pushes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com