Detachable pulsator plate of variable capacity washing machine

A washing machine and disassembled technology, which is applied to washing machines with containers, washing devices, textiles and paper making, etc., can solve the problems of cumbersome, unsatisfactory washing effect, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better explain the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but they do not limit the present invention.

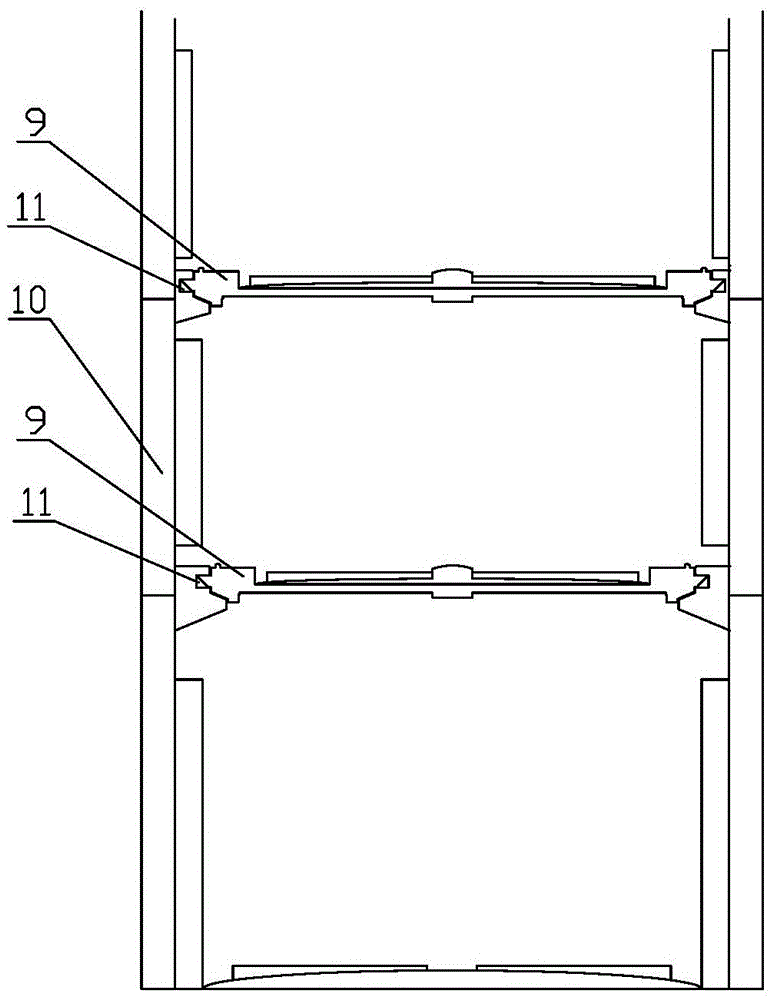

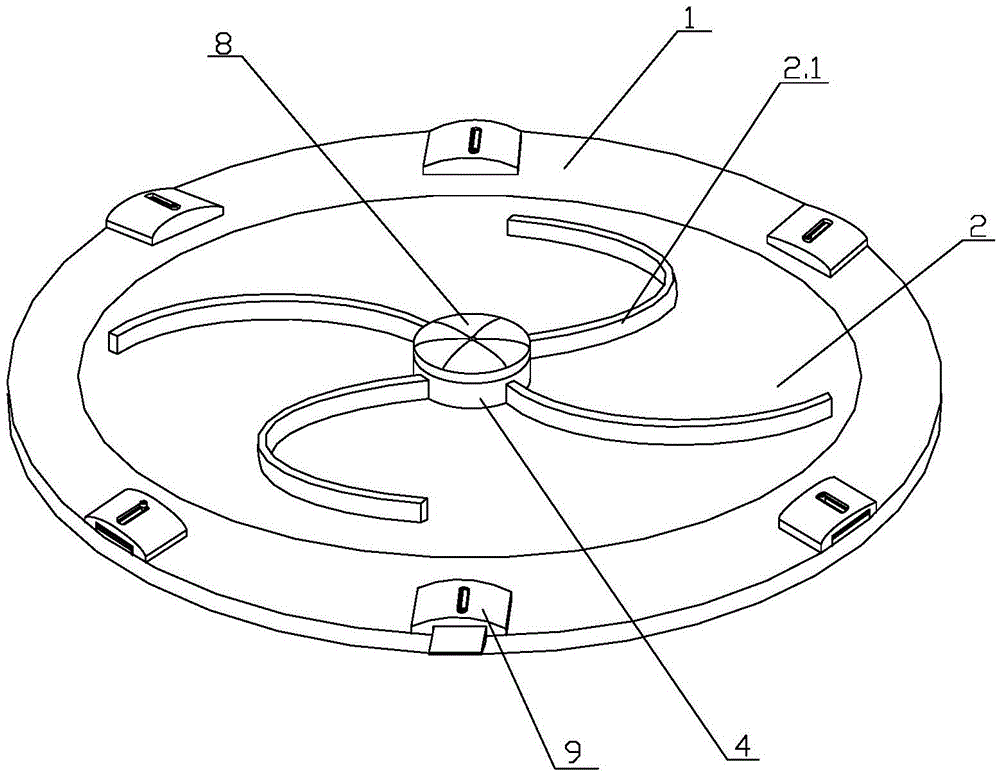

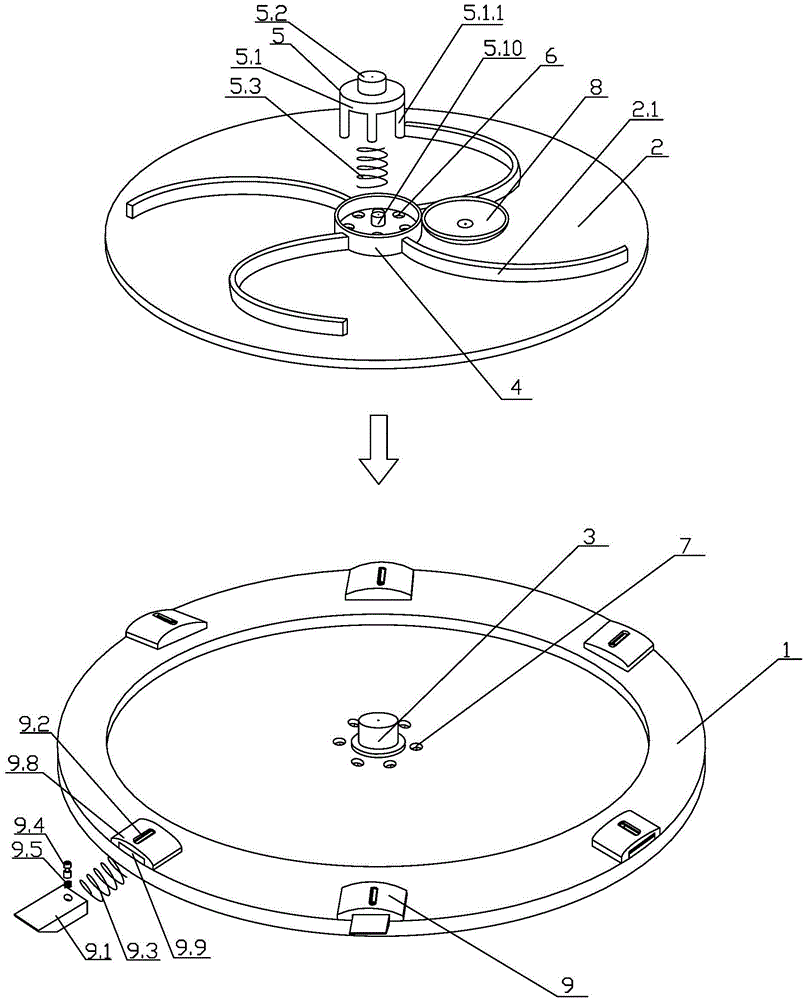

[0019] Figure 1~2 The detachable pulsator plate of the variable capacity washing machine shown includes a chassis seat 1 and a pulsator 2, as well as a self-locking latch 5 for locking the pulsator 2 on the chassis seat 1 and a plurality of self-locking pins for locking the chassis Seat 1 and washing tub 10 are installed as one snap lock device 9 . The center of the pulsator 2 is provided with a bearing seat 4, and the surface of the pulsator 2 is provided with a plurality of corrugated strips 2.1. The chassis base 1 and the pulsator 2 are coaxially stacked and connected by a bearing arranged at the center of the circle. The dehydration hole of the washing machine is arranged on the side wall of the washing tub 10 instead of the pulsator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com