Dismountable baffle plate sterilizing groove for preparing simvastatin

A technology of simvastatin and disinfection tank, which is applied in the field of detachable partition disinfection tank, can solve the problems of not being able to adapt to large-scale production, increase production costs, and high scrap rate, so as to improve space utilization, save labor, and reduce operating procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

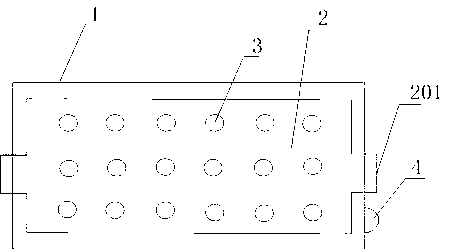

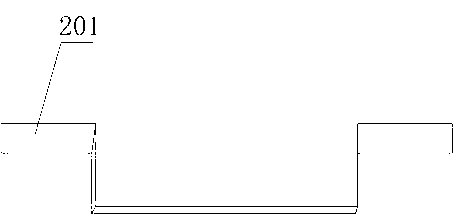

[0020] see figure 1 and figure 2 , a detachable partition disinfection tank for preparing simvastatin, comprising a rectangular tank body 1 and a partition board 2, the two sides of the above-mentioned partition board 2 are provided with barb handles 201, and the barb handles 201 pass through the rectangular tank body 1 is opened on both sides, and a plurality of holes 3 are also provided on the above-mentioned partition plate 2 .

[0021] When sterilizing, place the sterilizing utensils scattered on the partition 2 and the bottom of the rectangular tank body 1 to ensure that all the sterilizing utensils are submerged under the disinfectant solution, and tighten the faucet 4. Release the rectangular tank body 1, turn on water to clean it, and after cleaning, take the barb handle 201 out from the opening of the rectangular tank body 1, disassemble the partition plate 2, and take out the sterilizer for drying.

Embodiment 2

[0023] see figure 1 and figure 2 , similar to Example 1, the difference is:

[0024] The openings on both sides of the above-mentioned rectangular tank body 1 are located at 1 / 3 of the rectangular tank body 1. If the opening is too high, the amount of disinfectant solution required will be large, and if the opening is too low, the disinfectant solution may overflow from the contact between the opening and the barb handle 201, so moderate most.

[0025] The above-mentioned separator 2 is made of plastic or stainless steel.

[0026] The hole 3 is a circular hole or a regular polygonal hole, and the setting of the hole 3 is mainly to eliminate the blind area of disinfection, so as to avoid the occurrence of excessive contact of the disinfectant.

[0027] The outside of the above-mentioned rectangular tank body 1 is also provided with a faucet 4, and there are 2 or more faucets 4, and the number of the faucets 4 can be flexibly set according to the actual size of the disinfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com