A locking structure of a cable pin shaft

A pin and lock technology, which is applied to linear motion shafts, components with teeth, belts/chains/gears, etc., can solve the problems of complex assembly process and narrow space for shifting cables, and achieves simple assembly process, The effect of reduced space volume and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

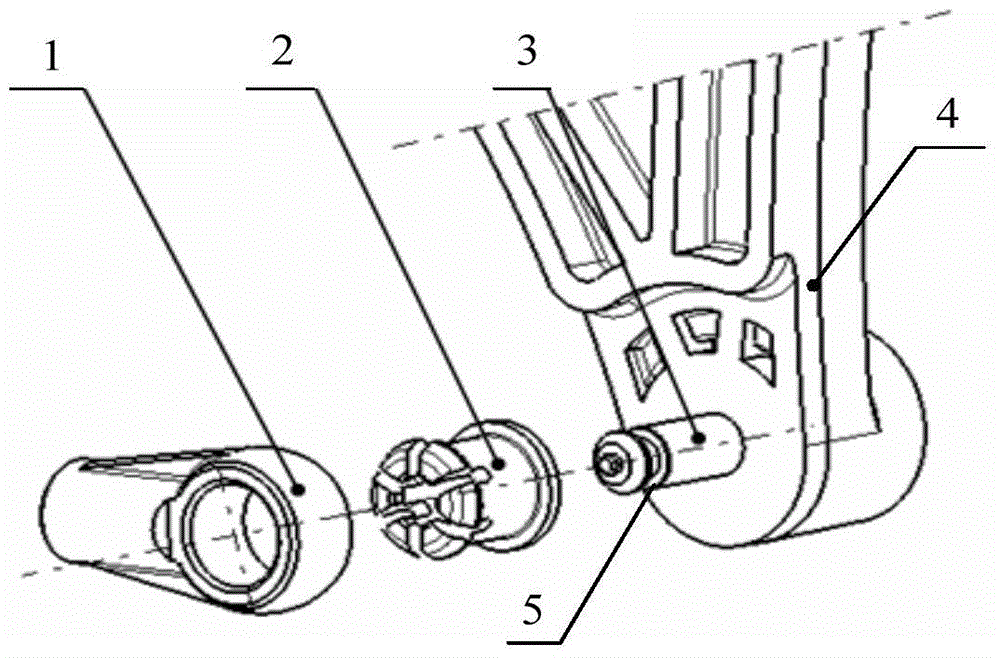

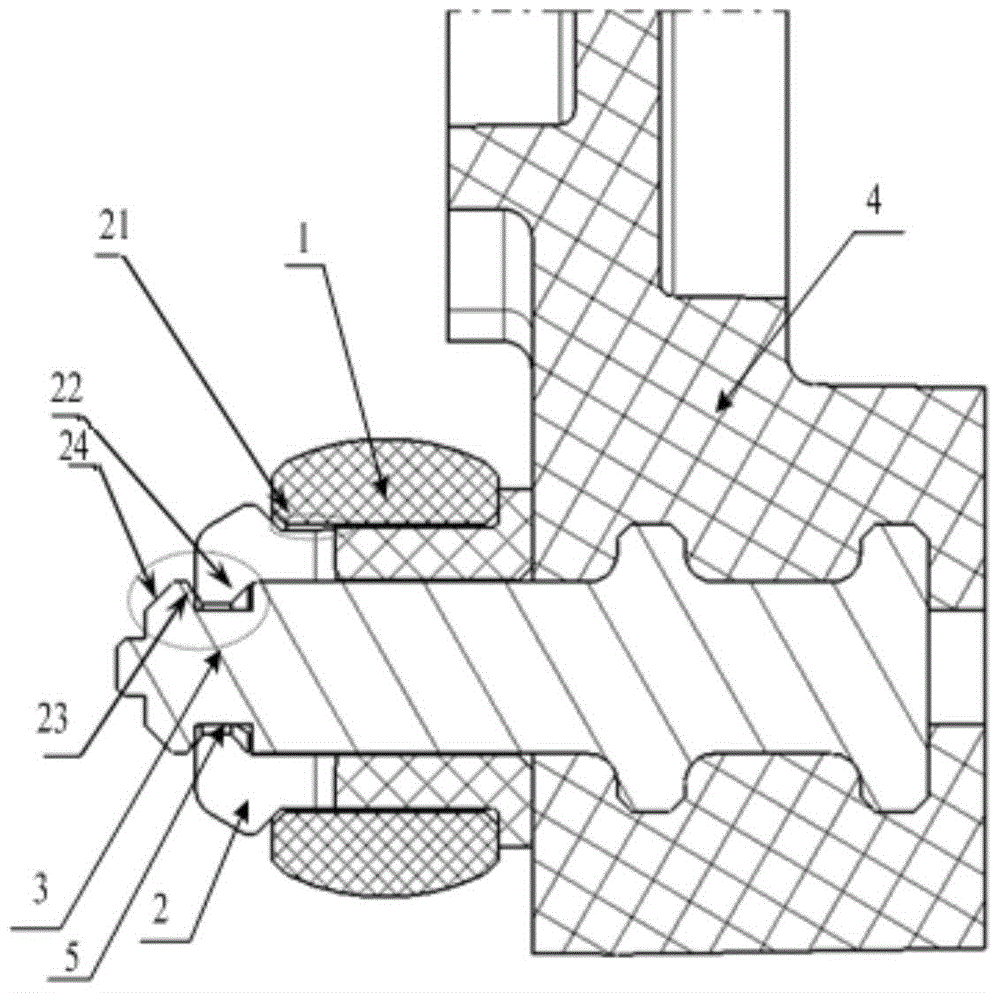

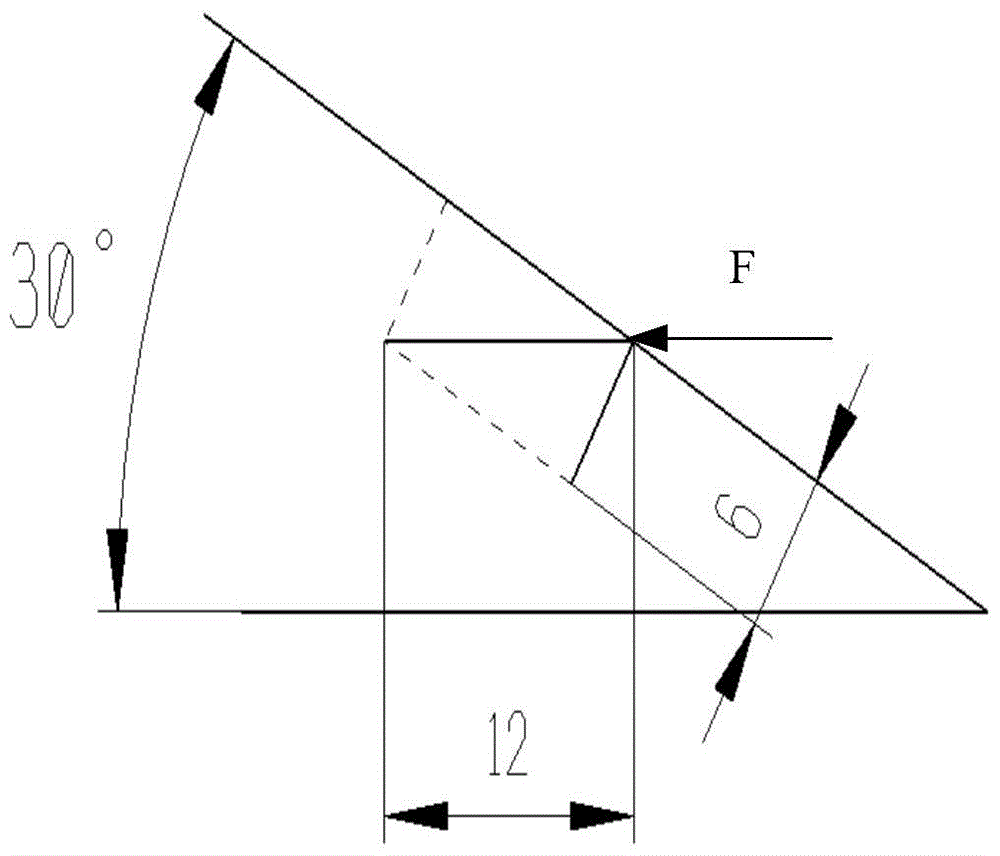

[0029] Such as figure 1 , figure 2 As shown, it is a cable pin locking structure, which is used for the quick cooperation between the shift cable and the shifter 4, including the cable joint 1 and the snap-in bushing 2 arranged on the shift cable and the shifter pin 3 located on the shifter 4; wherein, the clamping bushing 2 is hollow tubular, with a flange formed at one end and a flower-shaped opening at the other end; the cable joint 1 is sleeved on the outer surface between the flange of the clamping bush 2 and the flower-shaped opening; the shifter pin 3 is formed with an annular groove 5 at the end, and the shifter pin 3 Pass through and expand the flower-shaped opening from the inside of the clamping bush 2 , so that the end of the flower-shaped opening i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com