Fluid Connector Assembly

A connector assembly, fluid technology, applied in the direction of connection with fluid cut-off device, adjustable connection, pipe/pipe joint/pipe fitting, etc., can solve the problem that the connector plug cannot float radially.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

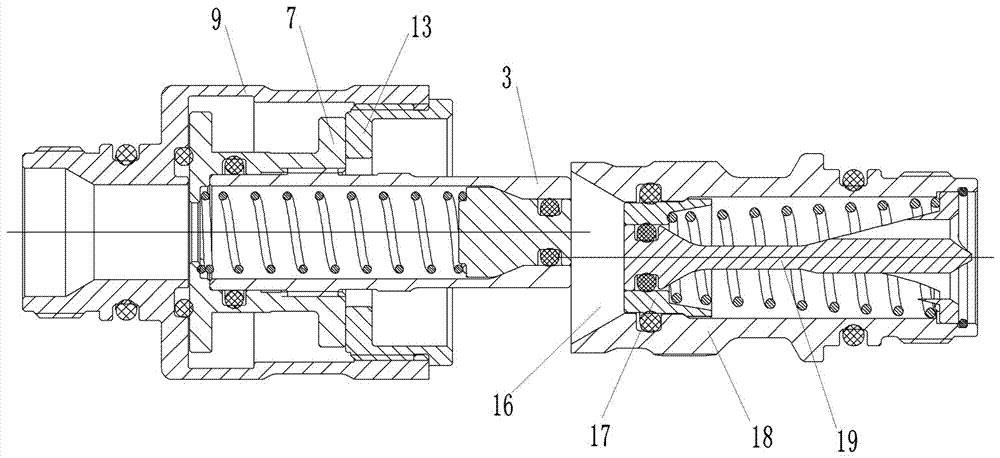

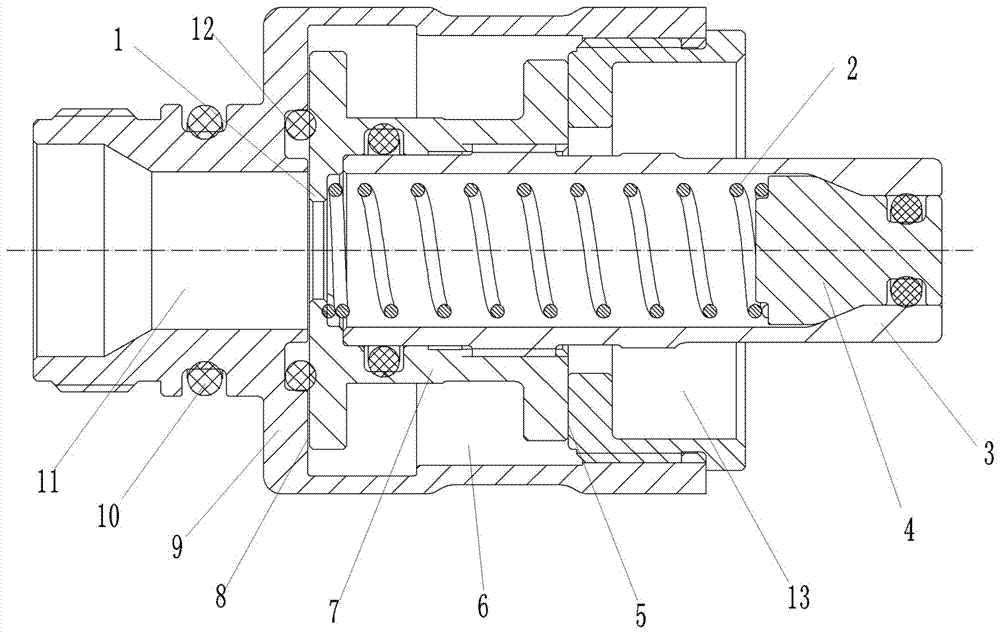

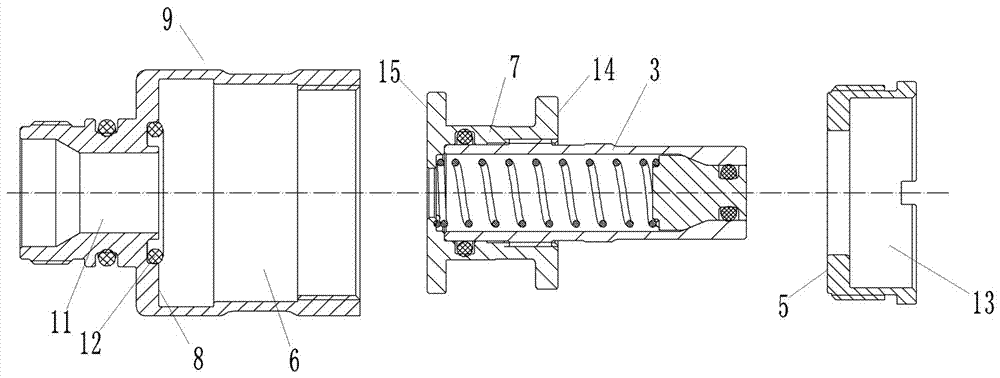

[0017] Examples of fluid connector assemblies are Figure 1~3 Shown: including plug and socket, including socket shell 18, socket fluid channel and socket spool 19 are arranged in the socket shell, the periphery of socket spool is elastically equipped with movable sealing sleeve 17, these all belong to prior art, in This will not be described in detail, the structural change on the socket housing is that a tapered guide surface 16 is provided at the front end of the socket housing. The plug includes a plug housing whose front end is a plug-in end. The plug housing includes a radial floating housing 7 and a cylindrical body 3 whose rear end is screwed on the radial floating housing 7. The connection between the cylindrical body 3 and the radial floating housing is A shell sealing ring is arranged between them, and the axis of the cylindrical body 3 extends along the front-to-back direction, and the inner guide movement of the cylindrical body is equipped with a plug spool 4 who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com