Liquid baffle structure and evaporator of air conditioning equipment

A technology for air-conditioning equipment and liquid baffles, which is applied to evaporators/condensers, lighting and heating equipment, refrigeration and liquefaction, etc., can solve problems such as low liquid removal efficiency, achieve low liquid removal efficiency, and improve liquid removal. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

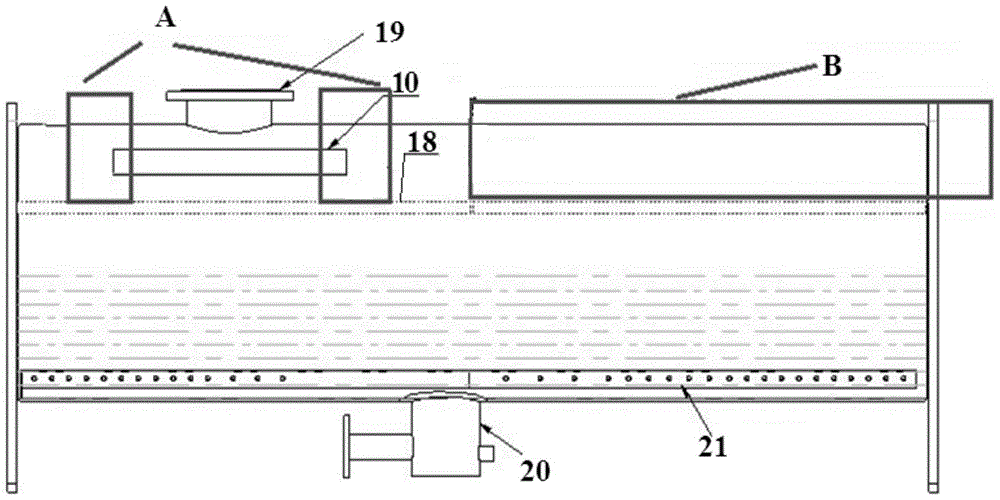

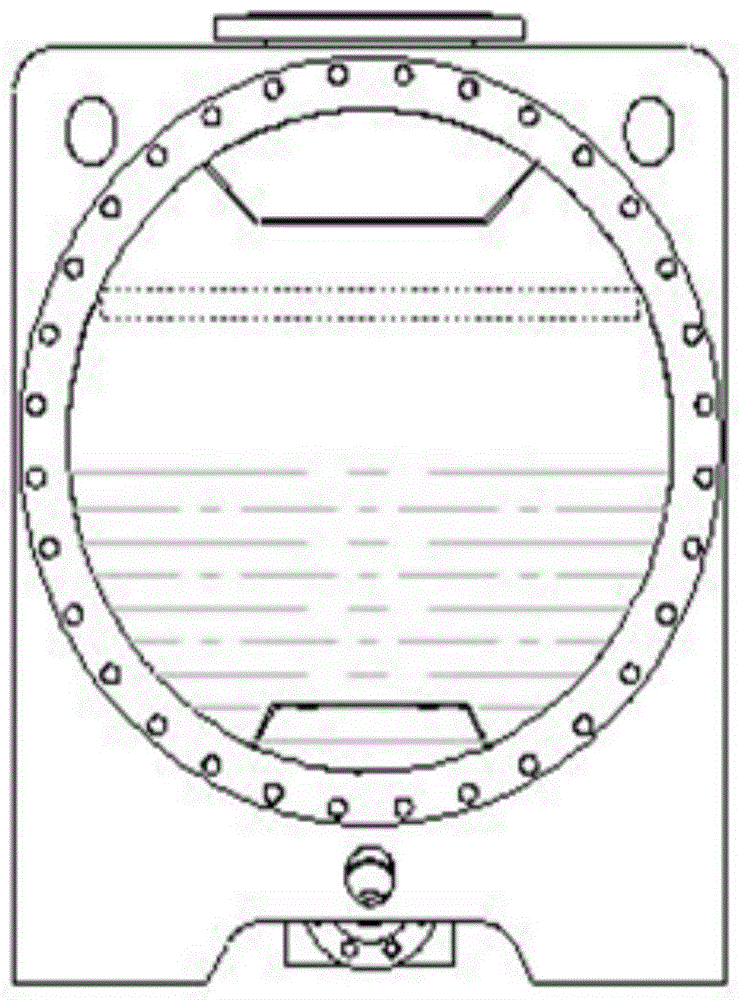

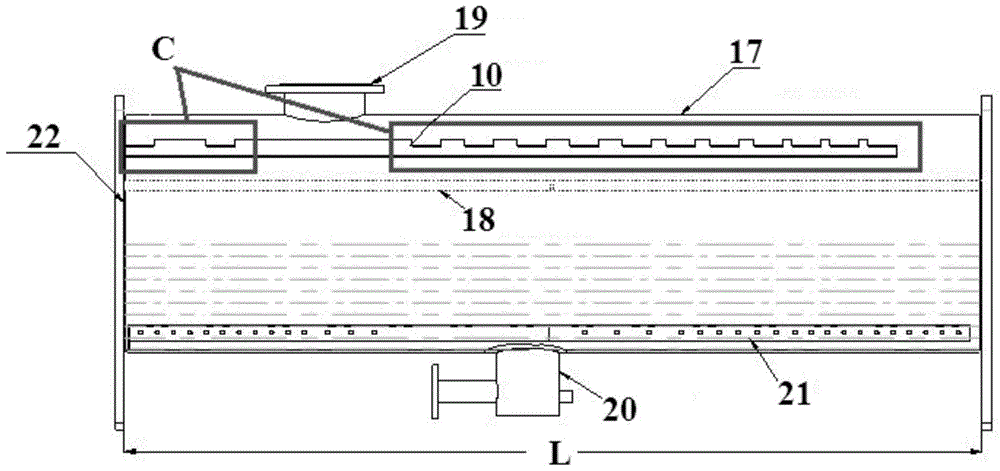

Embodiment 1

[0062] Such as Figure 9 ~ Figure 23 As shown, the liquid baffle structure provided by the embodiment of the present invention is used to block the liquid droplets in the refrigerant gas of the air conditioner. The liquid baffle structure includes a droplet blocking area and a droplet falling part (or called: drop point) 11 of the liquid baffle body portion 1, the drop blocking area is configured to enable the droplets condensed thereon to collect into the drop drop portion 11, the drop drop portion 11 is lower than the area around the drop drop portion 11 .

[0063] Since the droplet falling part 11 of the liquid baffle body provided by the embodiment of the present invention is lower than the area around the droplet falling part 11, compared with the trapezoidal structure in the prior art, there is a trapezoidal structure below the trapezoidal structure. On the droplet falling surface, the droplet falling part 11 on the droplet falling surface is at the same height as the s...

Embodiment 2

[0088] Such as Figure 24 and Figure 25 As shown, the difference between this embodiment and Embodiment 1 is that the cross-section of the body part 1 of the liquid baffle in the embodiment of the present invention includes a broken-line part. At this time, the outer contour of the section perpendicular to the longitudinal direction of the liquid baffle body 1 is in the shape of a broken line.

[0089] Such as Figure 24 The shown liquid baffle structure has a droplet falling part 11, such as Figure 25 There are two droplet falls 11 in the shown liquid baffle structure. Of course, more droplet falling parts 11 can also be provided as required.

Embodiment 3

[0091] Such as Figure 26 As shown, the difference between this embodiment and Embodiment 1 is that there are two droplet falling parts 11 in the liquid baffle structure in the embodiment of the present invention. Of course, more droplet falling parts 11 can also be provided as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com