Patents

Literature

36results about How to "Guaranteed centrifugal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

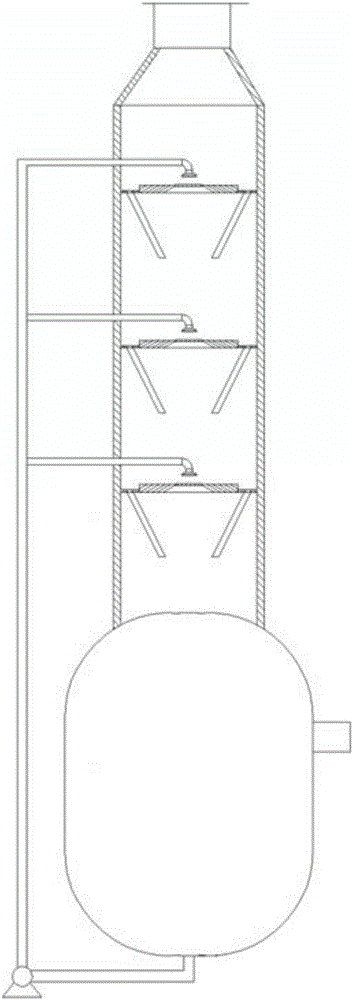

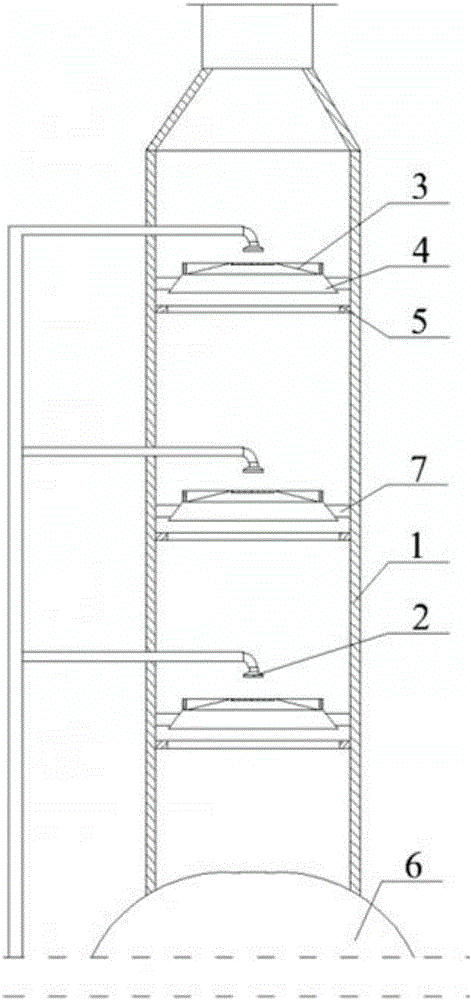

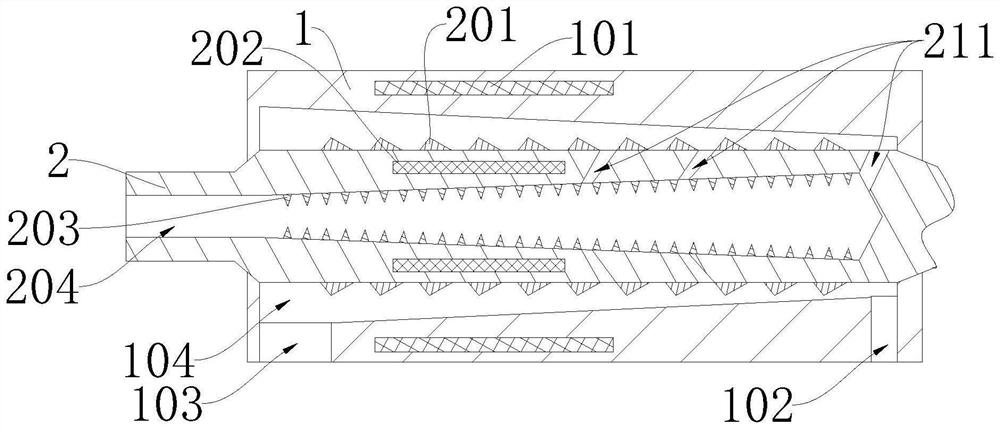

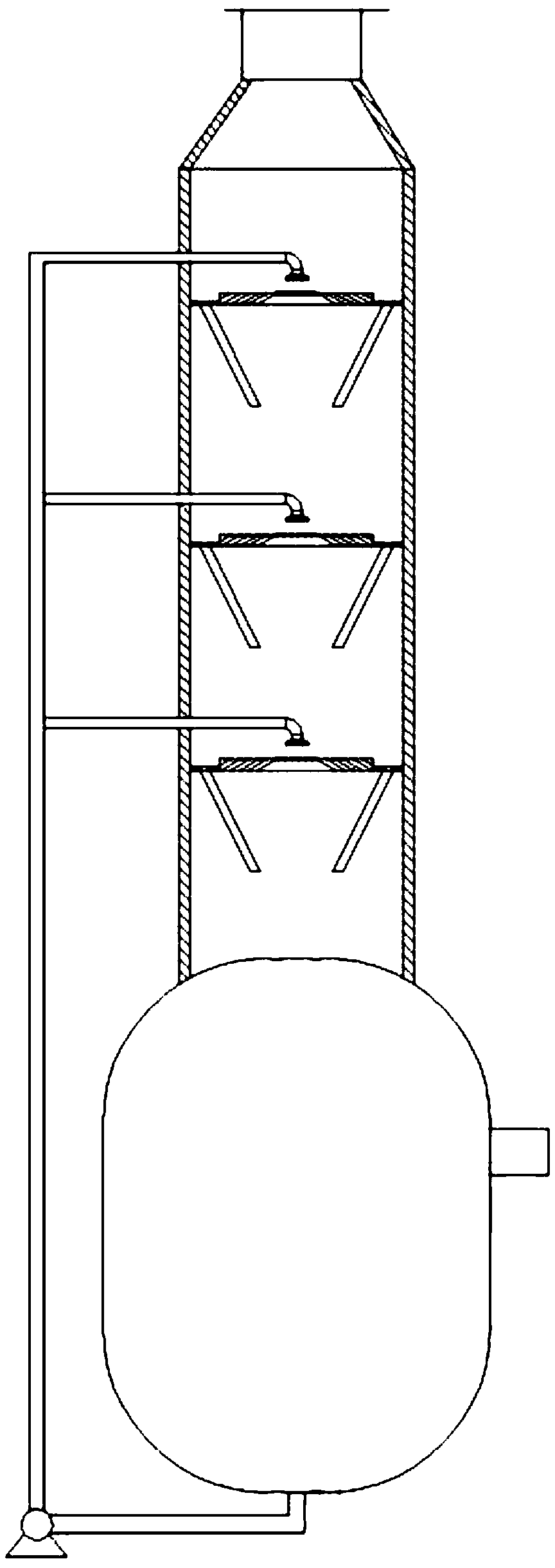

Multi-stage agglomeration and rotational flow combined method for removing liquid from gas

InactiveCN104941323AImprove liquid removal rateImprove liquid removal efficiencyAuxillary pretreatmentCycloneFlue gas

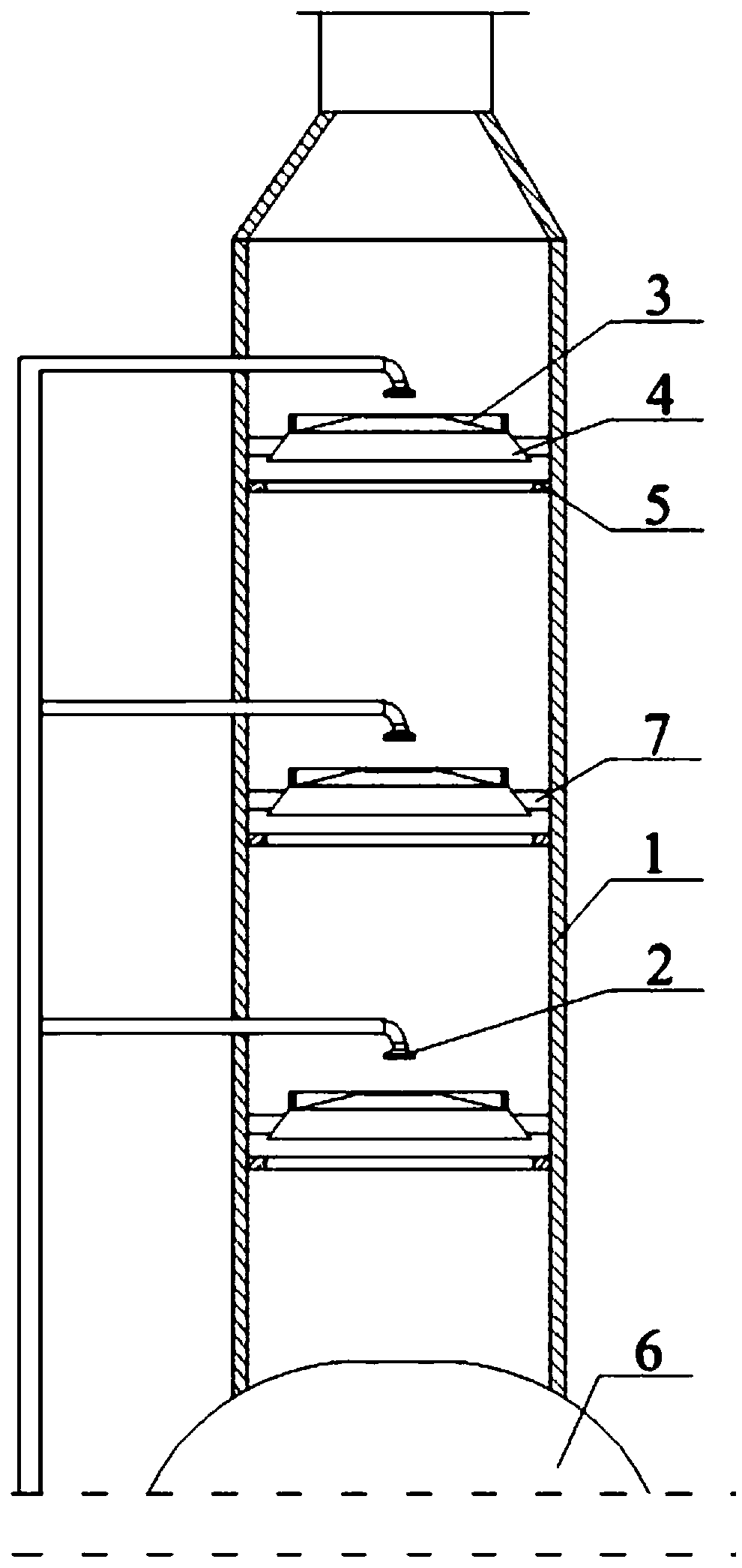

The invention provides a multi-stage agglomeration and rotational flow combined method for removing liquid from gas and belongs to the technical field of gas-liquid separation. The method is particularly used for dehydrating for removing liquid from gas discharged from a wet-process flue gas desulphurization device. According to the method, adopted devices comprise a tower body, an agglomeration zone, a multi-stage rotational flow liquid-removal zone and an exhaust barrel, wherein the agglomeration zone is composed of multi-stage staggered agglomeration plates; the multi-stage rotational flow liquid removal zone comprises a multi-stage cyclone and a connecting barrel; gas from a lower position is discharged from the exhaust barrel after being subjected to liquid removal through the agglomeration zone and the multi-stage rotational flow liquid removal zone and separated liquid is drained through a liquid drainage pipe and then flows into other lower zones.

Owner:QINGDAO JINGRUN PETROCHEM ENG

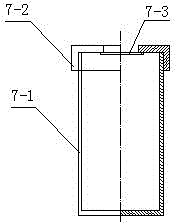

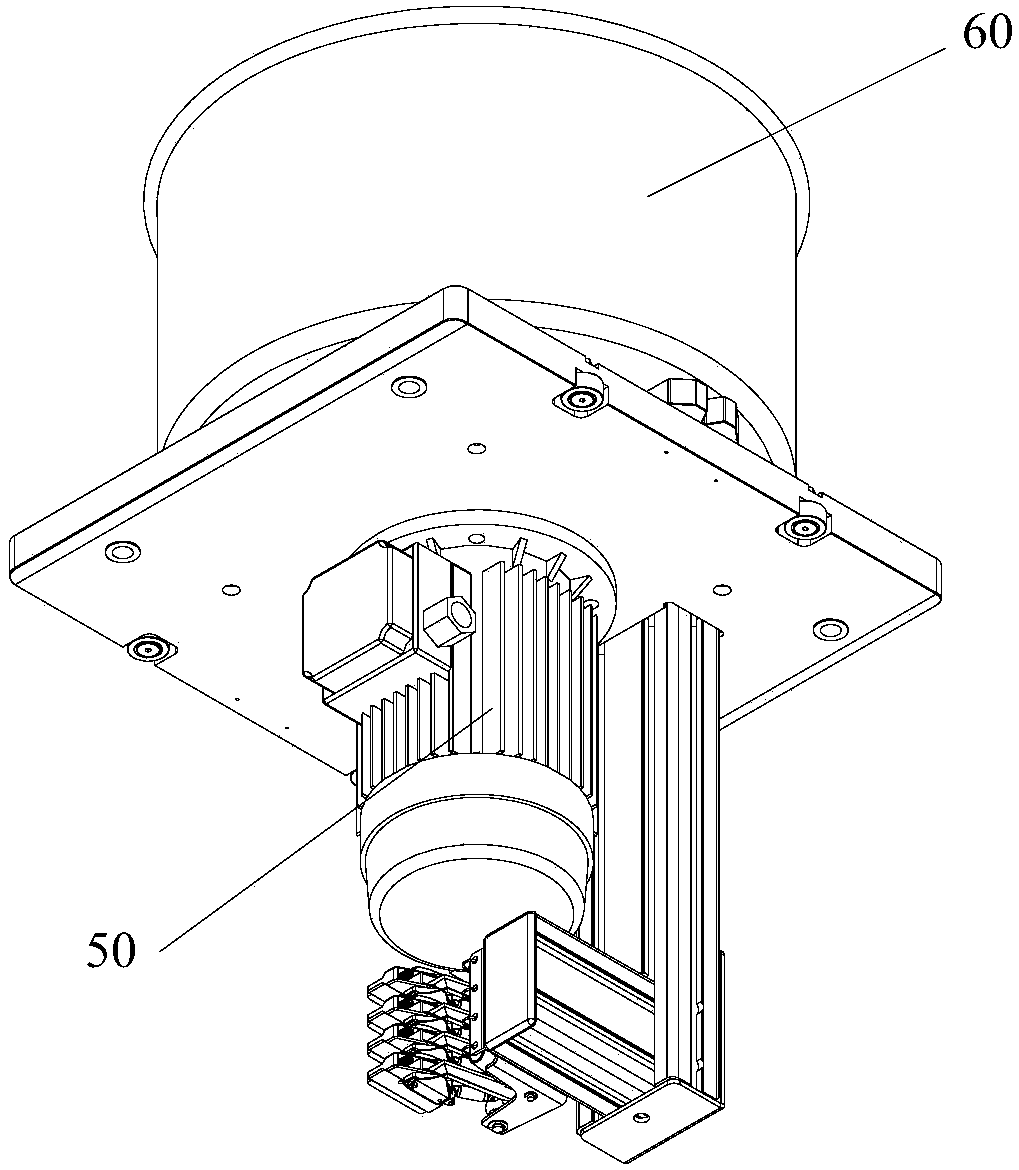

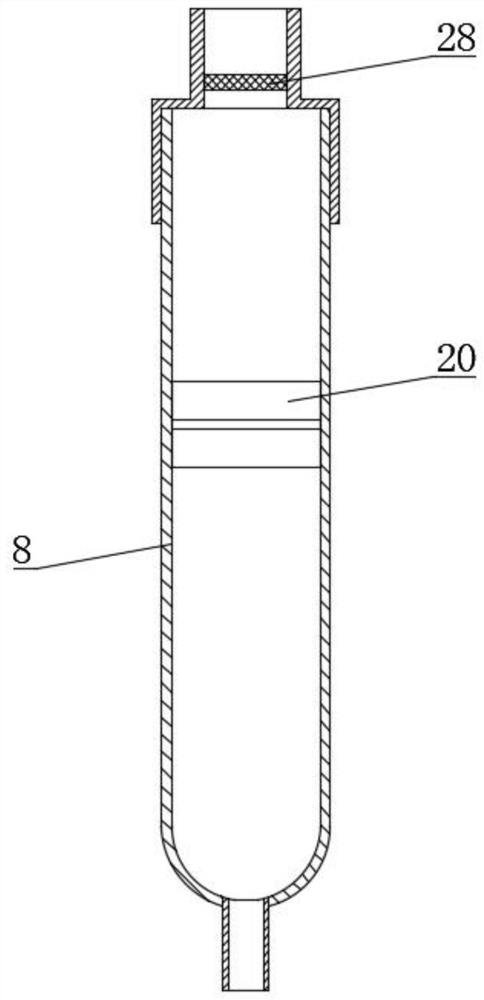

Micro centrifuge

The invention relates to the field of laboratory equipment, in particular to a micro centrifuge. The micro centrifuge includes a rotating shaft and a motor for driving the rotating shaft to rotate, wherein a turntable is fixedly connected with the rotating shaft; the turntable is fixedly connected with the middle of the rotating shaft; a rotating test tube is arranged on the turntable; the upper side and the lower side of the turntable are correspondingly provided with a first magnet and a second magnet that are connected with the rotating shaft in a thread mode; the first magnet and the second magnet move in opposite directions; reset members are connected with the first magnet and the second magnet; a first magnetic strip and a second magnetic strip are correspondingly arranged on the upper end and the lower end of the test tube; the first magnet and the first magnetic strip are attracted to each other; and the second magnet and the second magnetic strip repel each other. According to the micro centrifuge, it is convenient for medical staff to read the scale on the test tube, so that reading errors are reduced.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

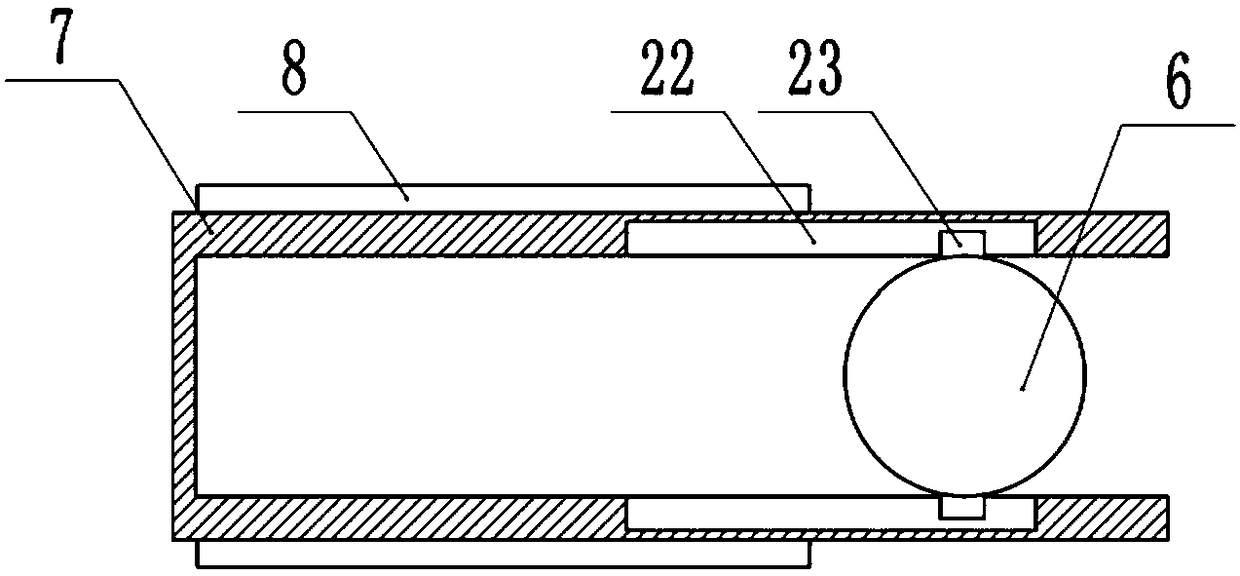

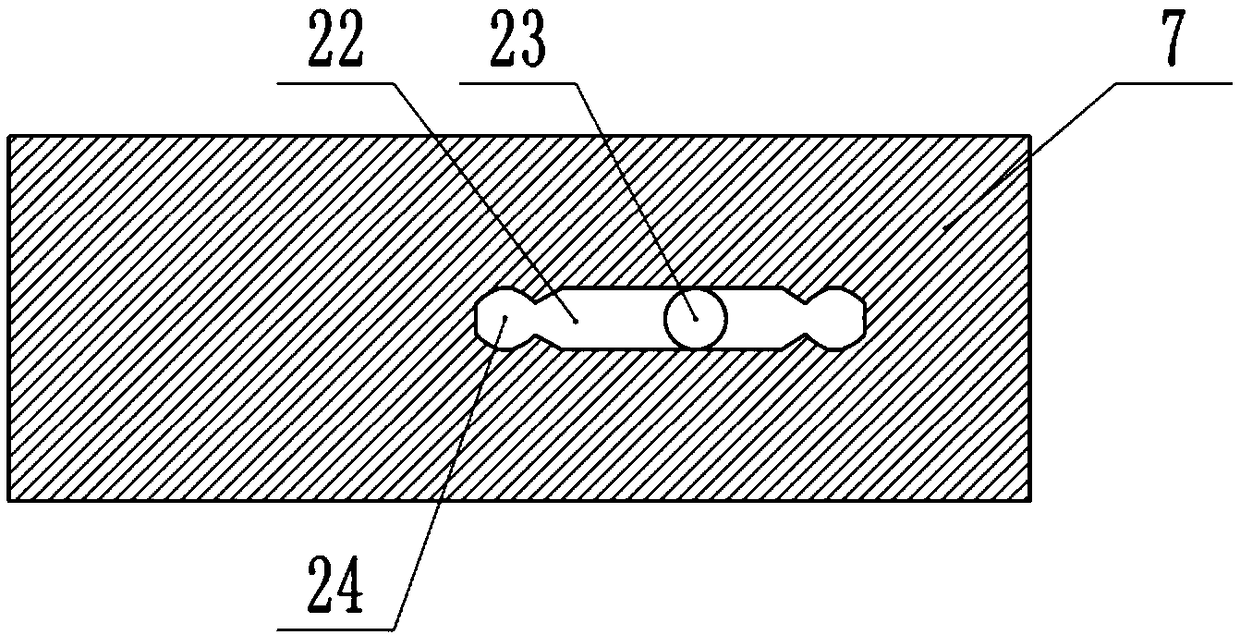

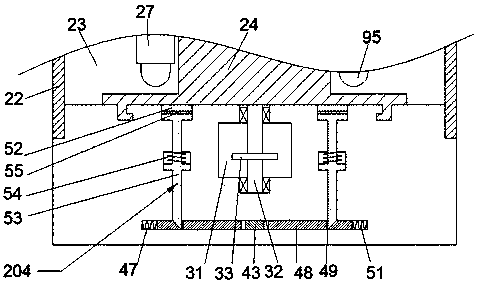

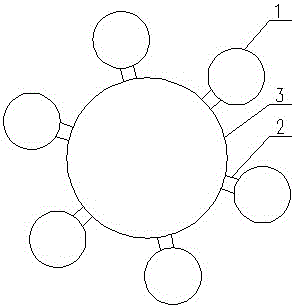

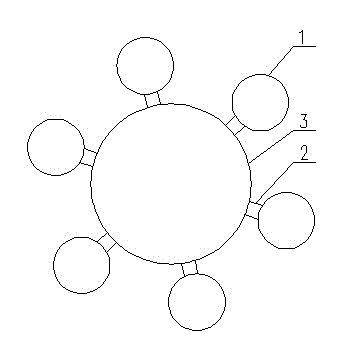

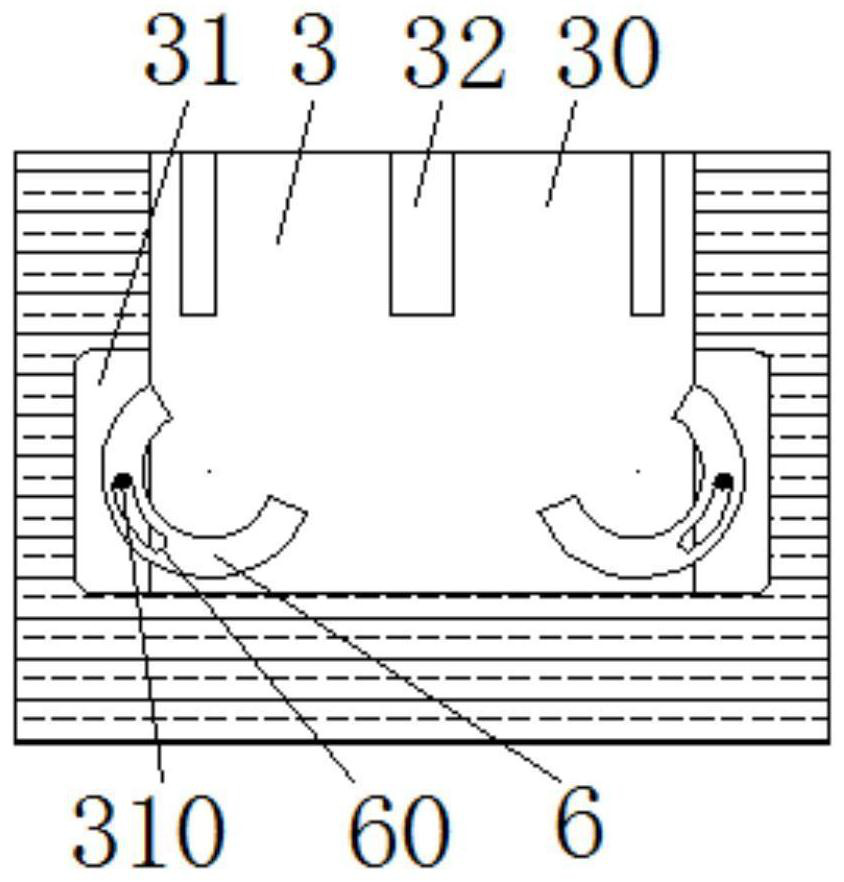

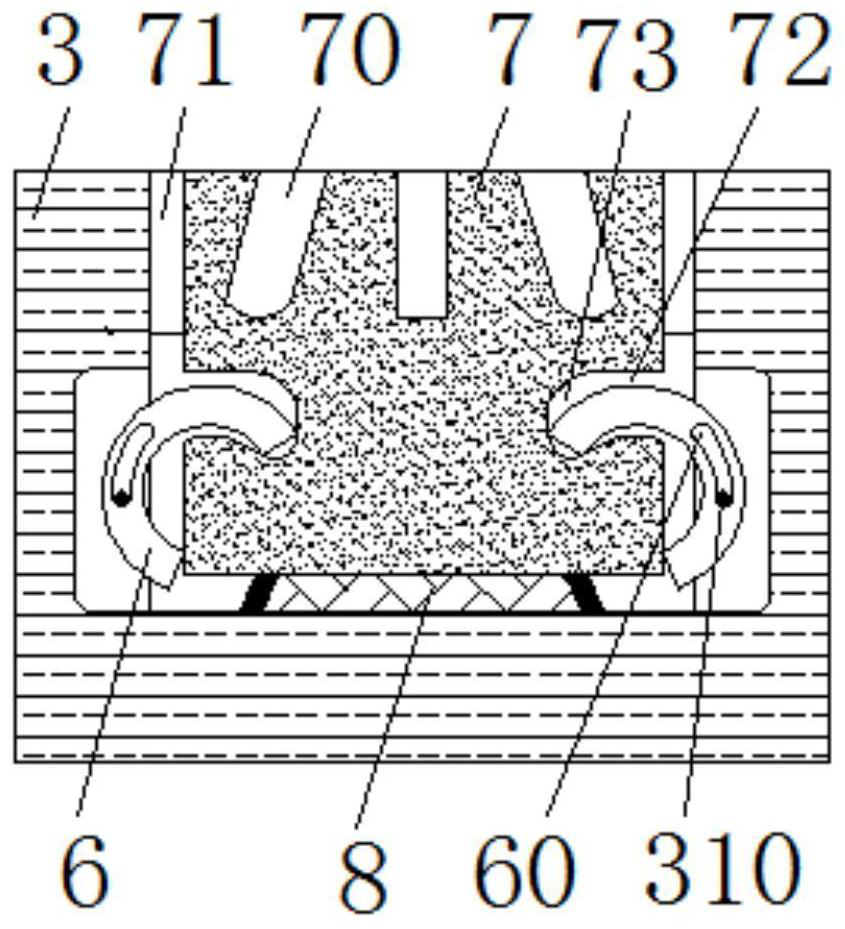

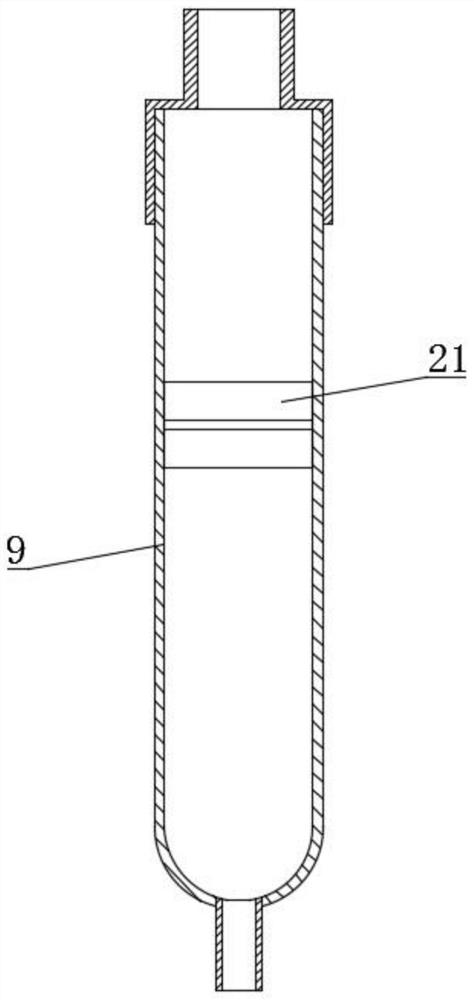

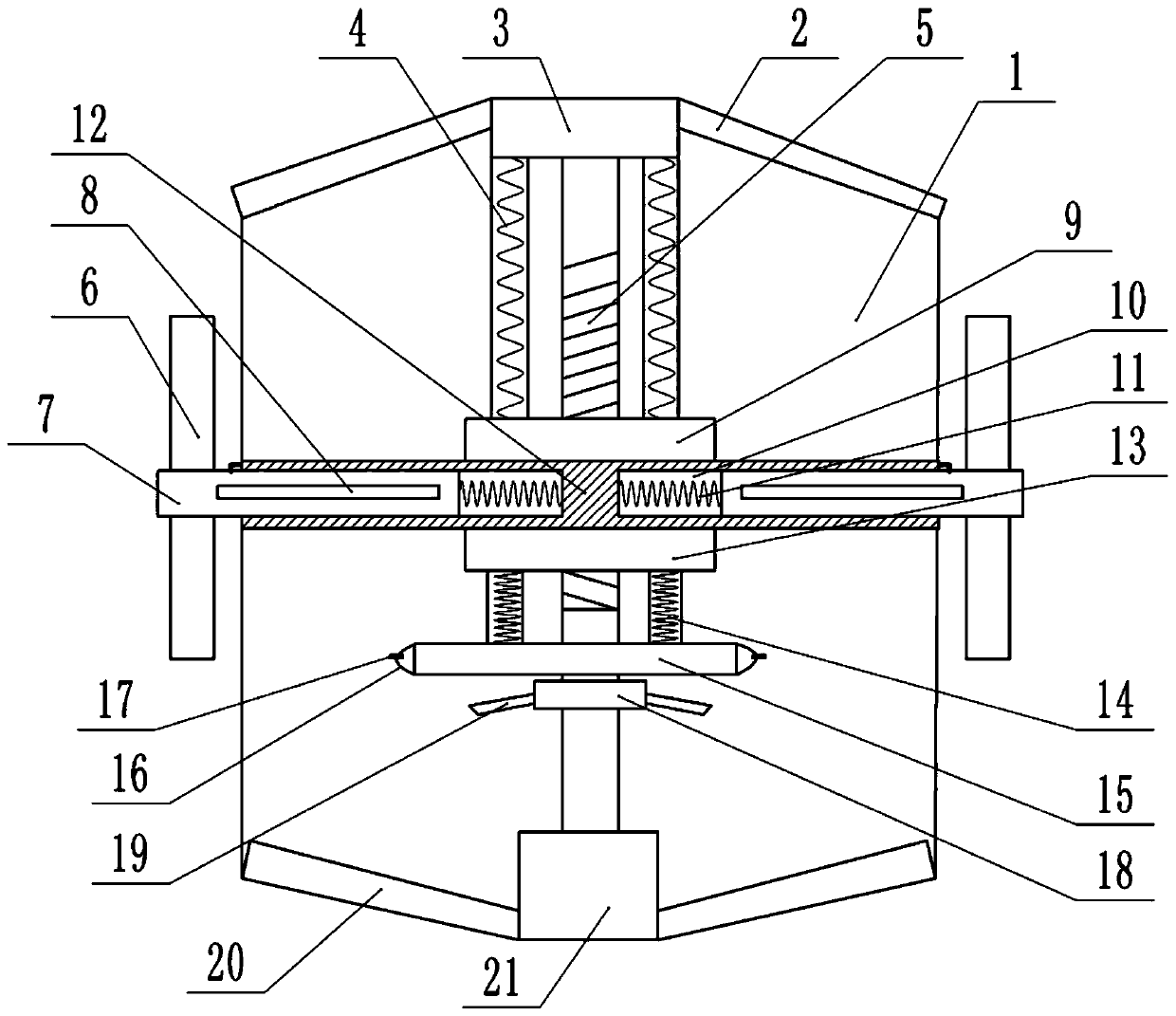

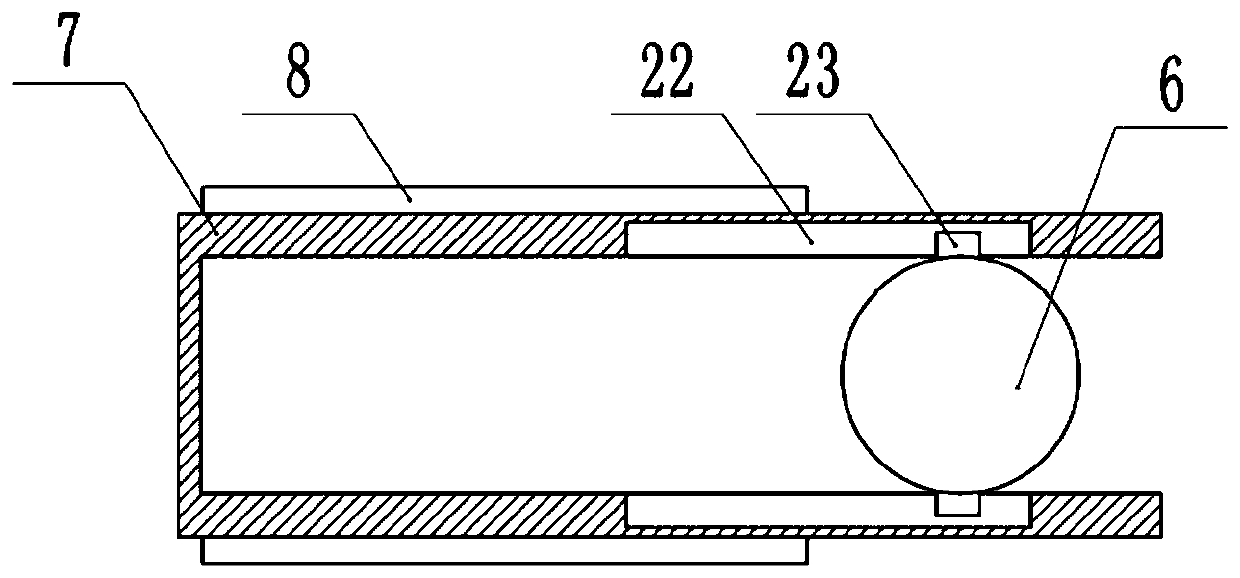

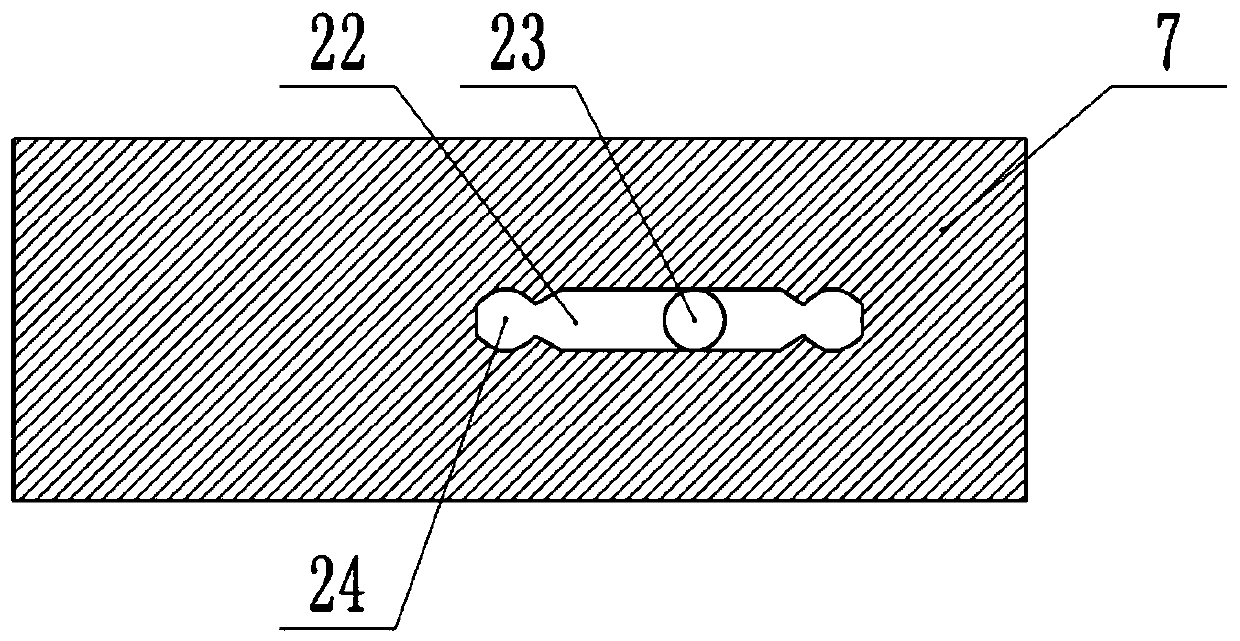

Portable type blood centrifugal machine

The invention discloses a portable type blood centrifugal machine. The portable type blood centrifugal machine comprises a base, wherein the upper side of the base is equipped with a top cover; a centrifugal cavity is arranged between the inner part of the top cover and the upper end surface of the base; a rotary block is rotatably arranged in the centrifugal cavity; six test tube placing devicesare uniformly distributed at the periphery of the rotary block; the test tube placing devices are used for placing test tubes; and a power device is arranged in the upper end surface of the base. Theportable type blood centrifugal machine disclosed by the invention adopts a portable type design, is small in size, is convenient in carrying, and adopts a metal counterweight block to share weight, so that centrifugal rotation is more uniform, occurrence of vibrations is effectively reduced, and shutdown regulating probability is reduced; meanwhile, during centrifuging, the test tubes are in thehorizontal state, so that blood layering can be promoted better; and while centrifuging is ended, flowing among layers is reduced, so that the centrifugal effect is guaranteed.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

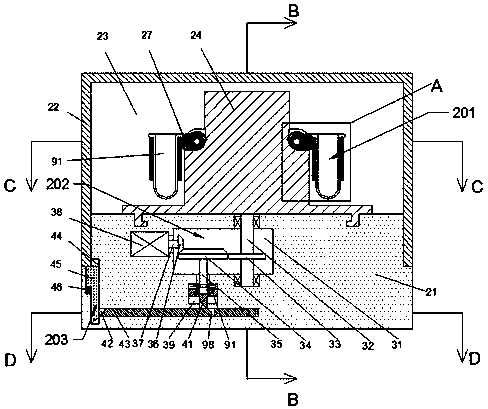

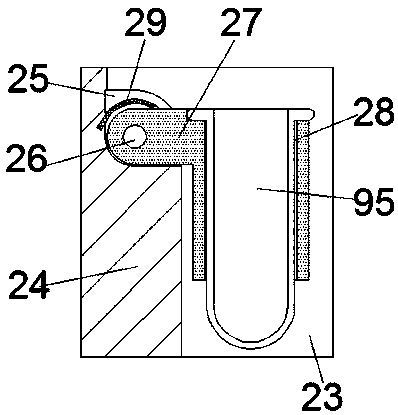

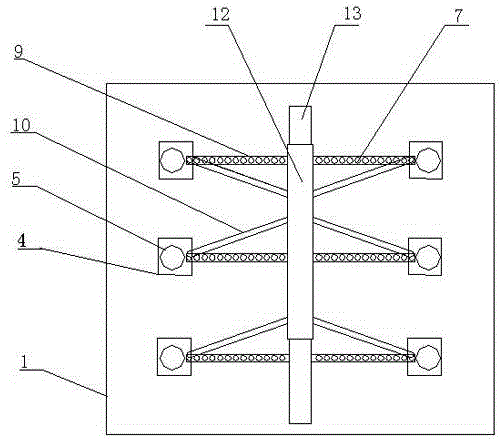

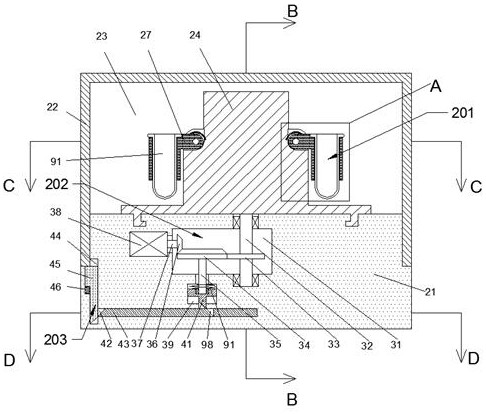

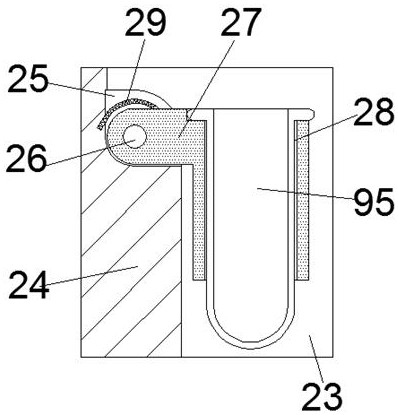

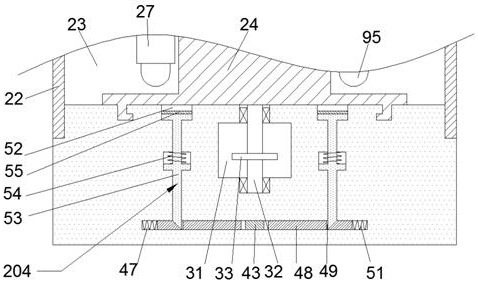

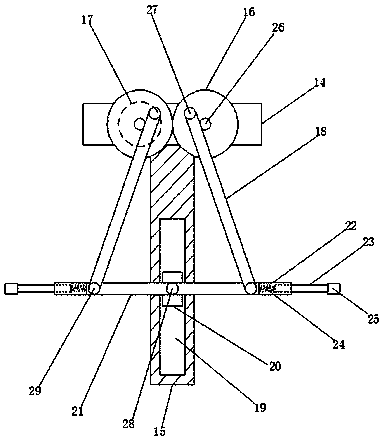

Intelligent blood centrifugation balancing instrument and balancing method

InactiveCN104061988ARealize automatic trimTrim is simpleMaterial check-weighingSolenoid valveCentrifugation

The invention provides an intelligent blood centrifugation balancing instrument and a balancing method. The intelligent blood centrifugation balancing instrument is characterized in that the adopted balancing object comprises plastic cement balancing rods and liquid filler, wherein each of the plastic cement balancing rods is a hollow rod with one end open, and a plug or an elastic closing cover is arranged at the open end. On the basis of the intelligent balancing instrument, a balancing filler chamber is arranged in a case, six feeding tubes independent to each other are connected to a discharging port in the balancing filler chamber, and solenoid valves are arranged on the feeding tubes. A magnetic core push rod of a push electromagnet drives feeding ports of the feeding tubes to move to be in butt joint with the corresponding plastic cement balancing rods in centrifugation lining buckets on trays of electronic balances, the feeding tubes return to the original places after feeding, and the push electromagnet, the solenoid valves and weighing sensors are connected with a board of a single-chip microcomputer. The intelligent blood centrifugation balancing instrument is capable of performing balancing simply, conveniently and accurately and high in automation degree. The balancing object is reasonable in structure and capable of being filled conveniently, formation of centrifugal dead space is prevented effectively, and risk of centrifugal breakage is reduced.

Owner:QINGDAO BLOOD CENT

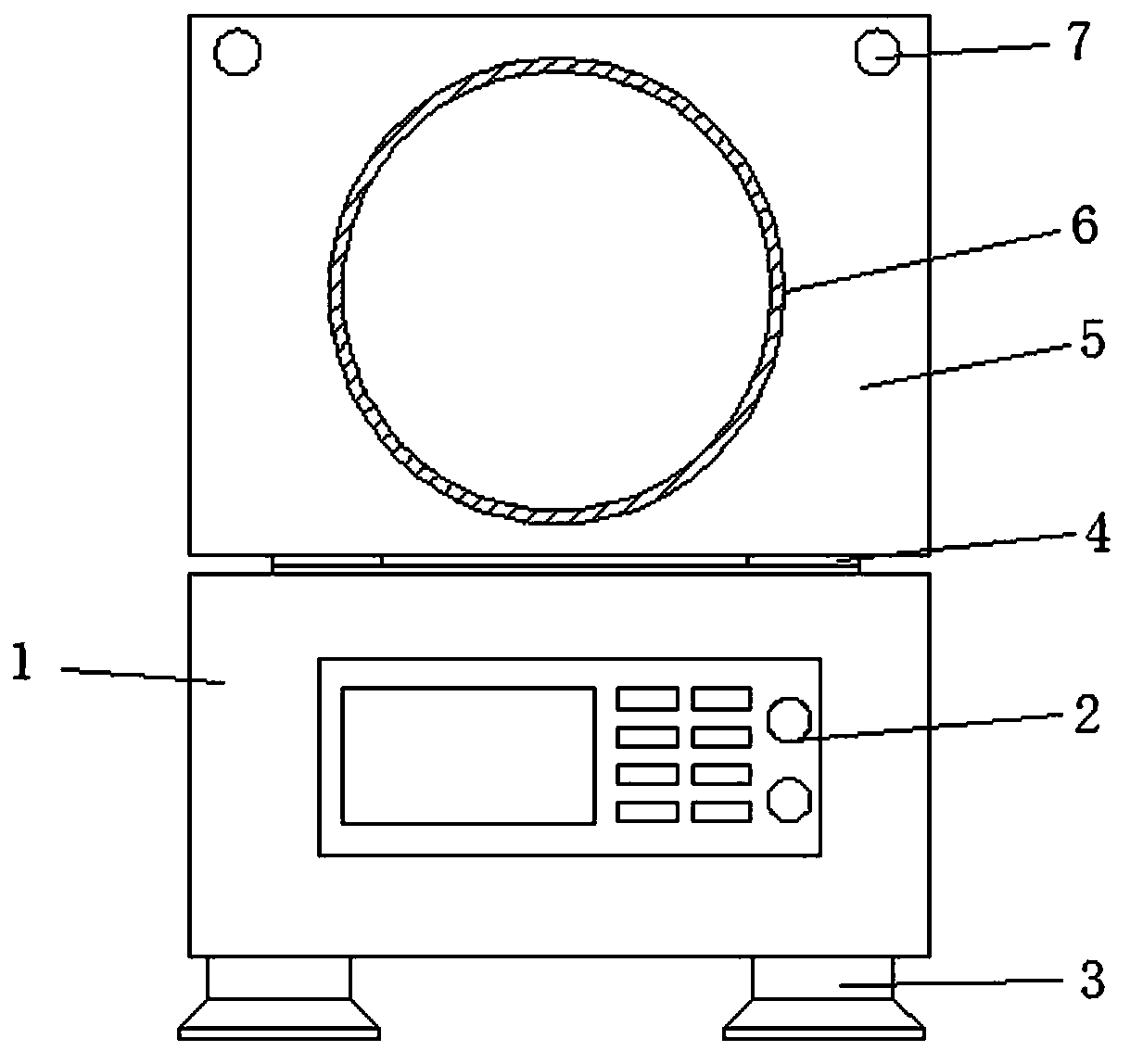

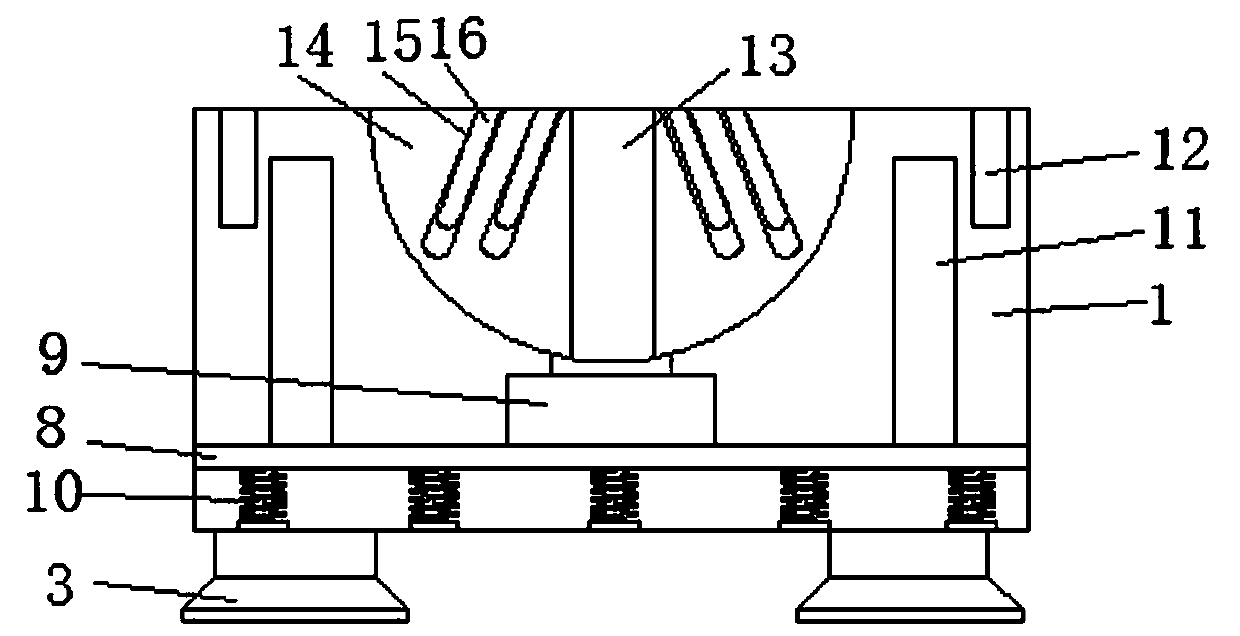

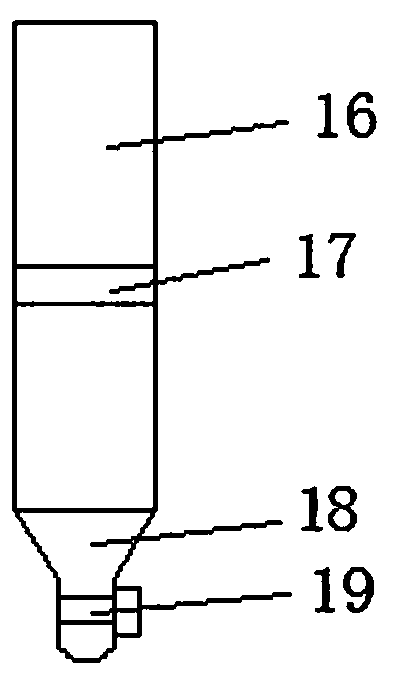

Centrifugal machine for pharmaceutical manufacturing

InactiveCN109530101AImprove sealingFirmly connectedEngine sealsNon-rotating vibration suppressionVolumetric Mass DensitySolid particle

The invention discloses a centrifugal machine for pharmaceutical manufacturing. The centrifugal machine comprises a machine case, a case cover, a centrifugal bin and a centrifugal tube, wherein a baseis arranged at the bottom of the machine case, the base is fixedly connected with the machine case through bolts, a controller is arranged on the surface of the machine case, the controller is fixedly connected with the machine case through bolts, a hinge is arranged at the upper part of the machine case, the case cover is arranged on the upper part of the hinge, the case cover is rotationally connected with the machine case through the hinge, a supporting plate is arranged in the machine case, a motor is arranged on the upper portion of the supporting plate, and the motor is fixedly connected with the supporting plate through bolts. According to the centrifugal machine for pharmaceutical manufacturing, the motor is started through the controller to drive a connecting shaft to rotate so as to enable the centrifugal bin to rotate, liquid with different densities in the centrifugal tube is separated by centrifugal force, a separation screen arranged inside the centrifugal tube can separate solid particles in the liquid, the liquid separation is facilitated, a liquid outlet is opened by rotating a control valve, the internal separated liquid is discharged and solid-liquid separationis realized.

Owner:江苏特克菲勒生物科技有限公司

Centrifugal machine

ActiveCN112170023ACentrifugal realizationIssues affecting the accuracy of subsequent testsCentrifugesRadiationEngineeringApparatus instruments

The invention relates to the technical field of medical instruments, and particularly discloses a centrifugal machine. The centrifugal machine comprises a placing frame and a rotary disc. Test tube holes used for placing test tubes are formed in the placing frame. The placing frame is connected to the rotary disc. Clamping sets are arranged in the placing frame, and each clamping set comprises clamping blocks symmetrically arranged along the test tube holes. The clamping blocks are slidably connected to the placing frame. The centrifugal machine further comprises a cover opening mechanism anda negative pressure mechanism. The cover opening mechanism comprises lifters and cover opening discs. The lifters drive the cover opening discs to ascend and descend. Guide rods are fixedly connectedto the cover opening discs. Cover openers are further connected to the cover opening discs. The guide rods can push the clamping blocks to move so as to clamp the test tubes, and the cover openers areused for opening test tube covers. The negative pressure mechanism generates negative pressure after the test tubes are uncovered so as to pump away the aerosol. According to the scheme of the centrifugal machine, the problems that in the prior art, after a specimen in a test tube is uncovered, the aerosol brings harm to medical staff, and after the specimen in the test tube is centrifuged, the specimen is moved and then uncovered, the operation is troublesome are solved.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

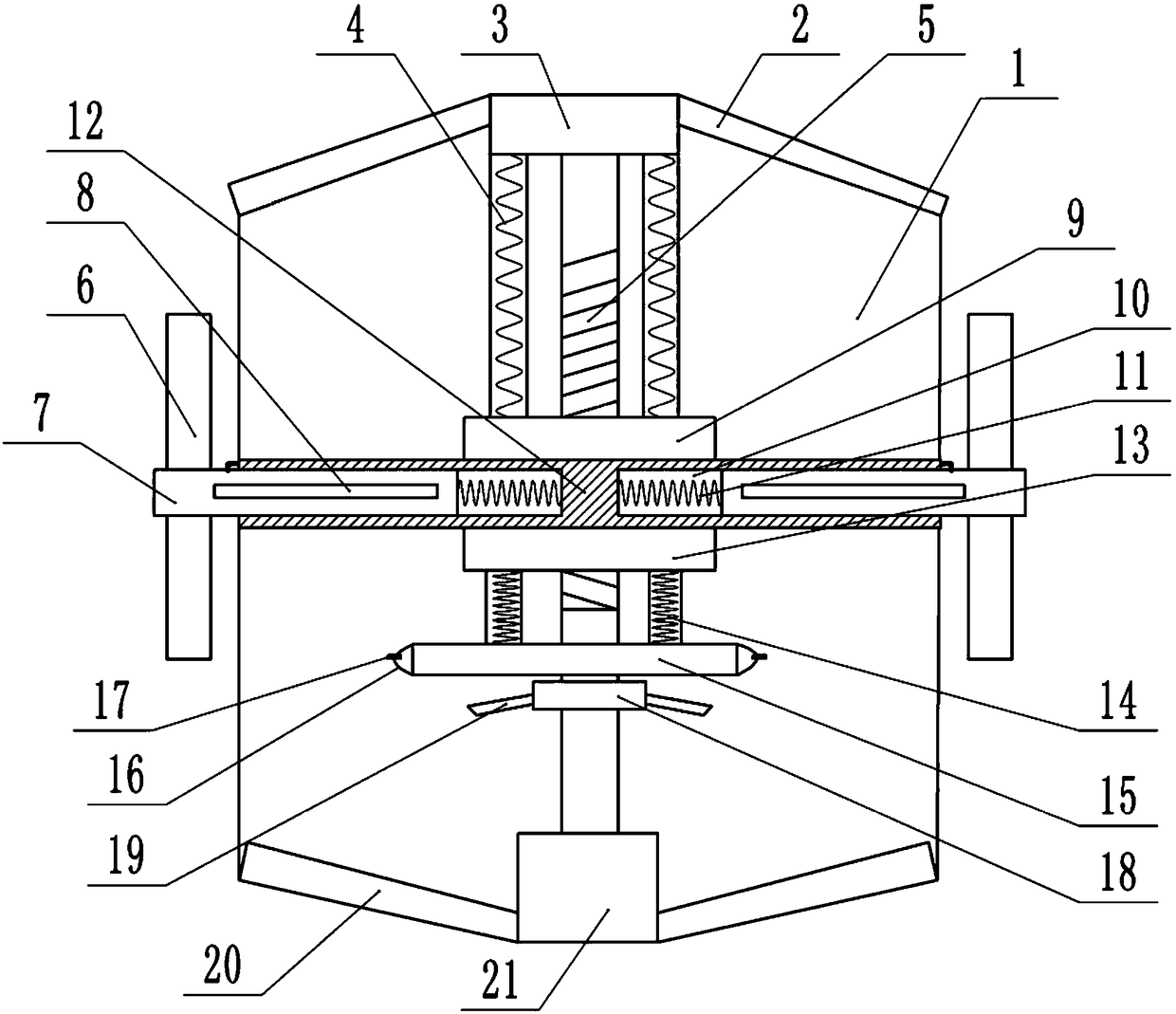

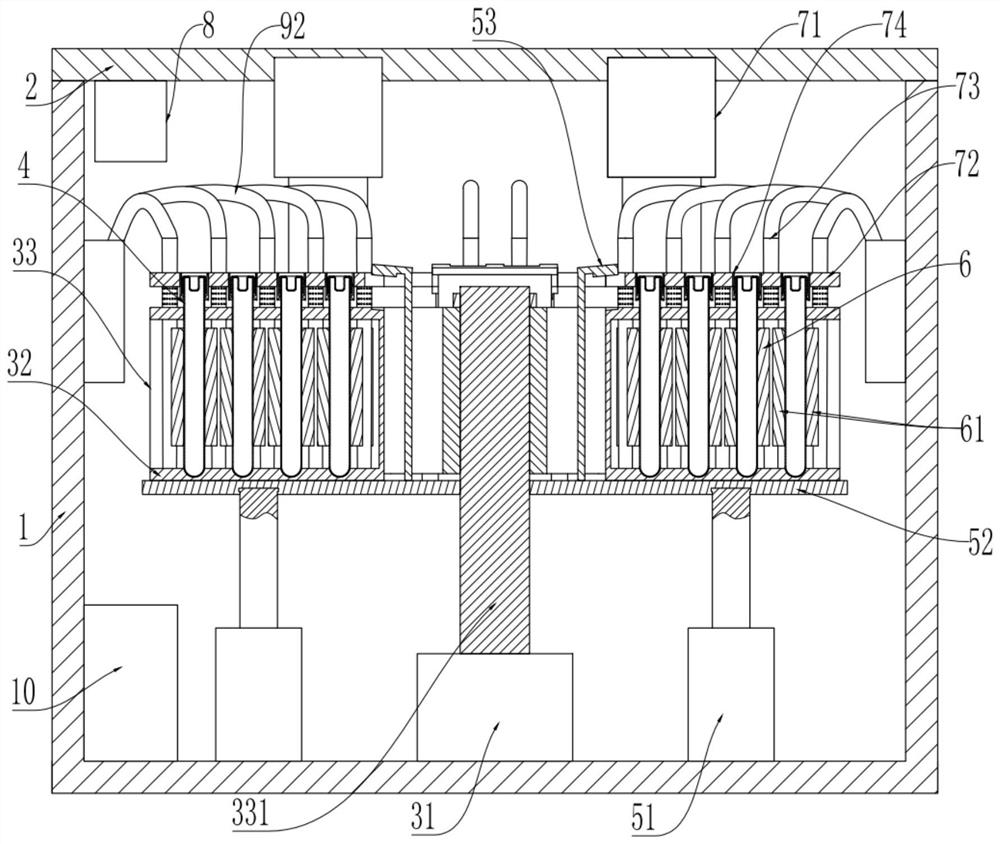

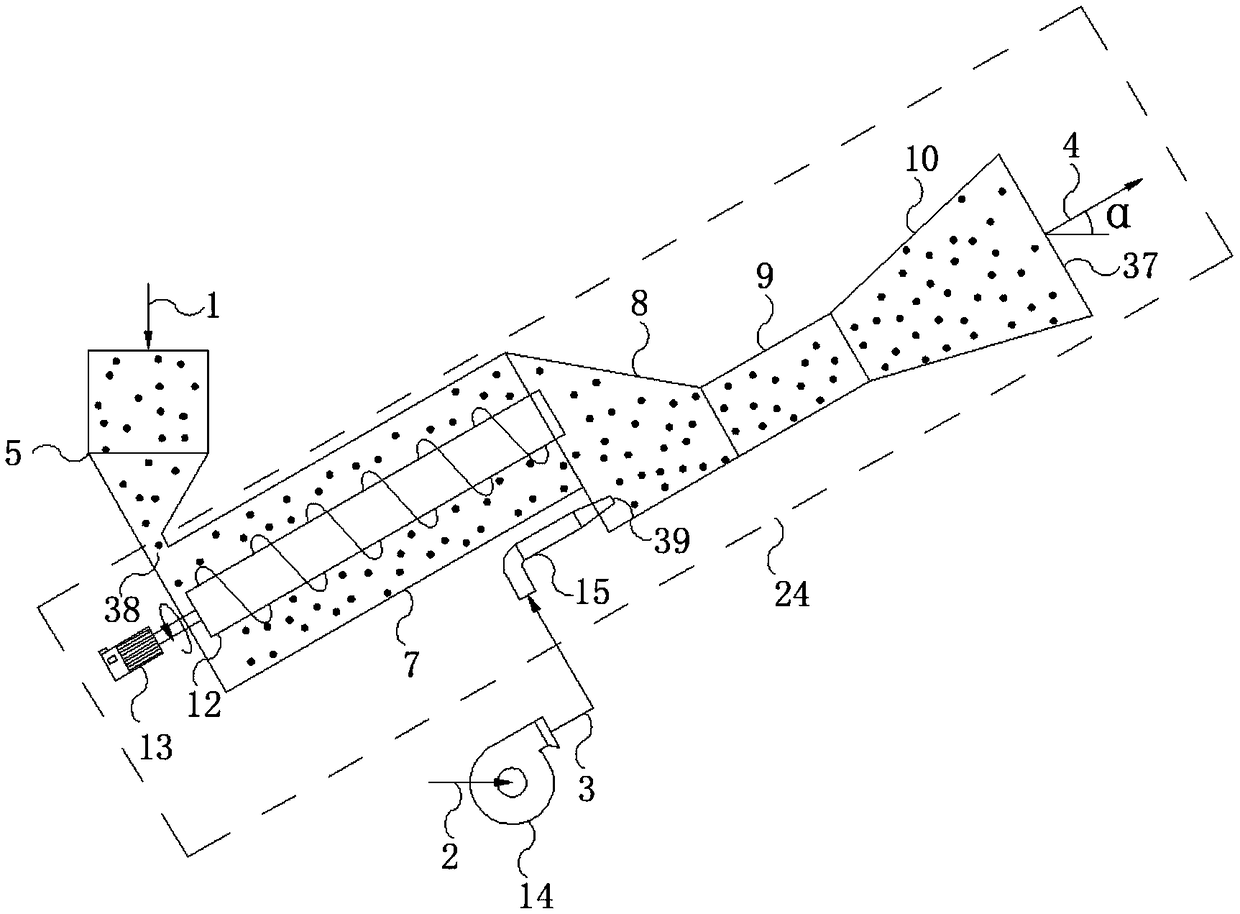

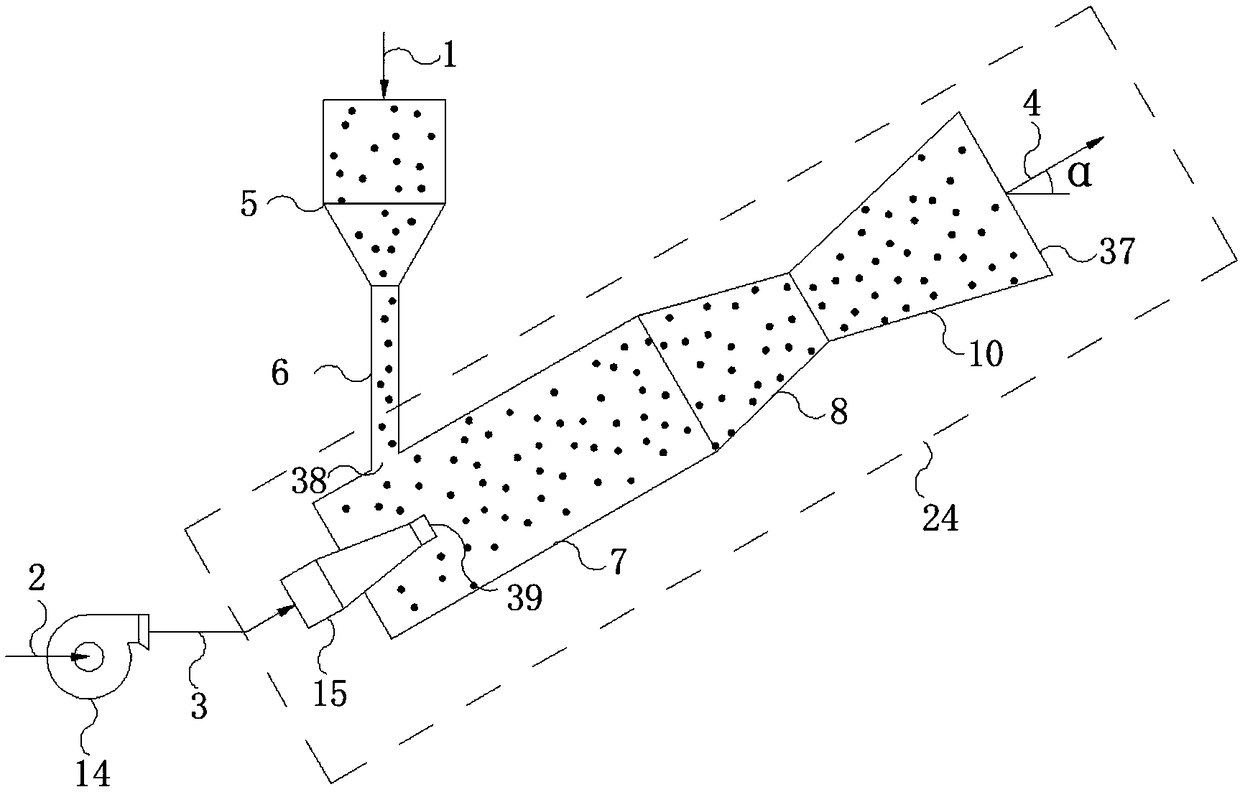

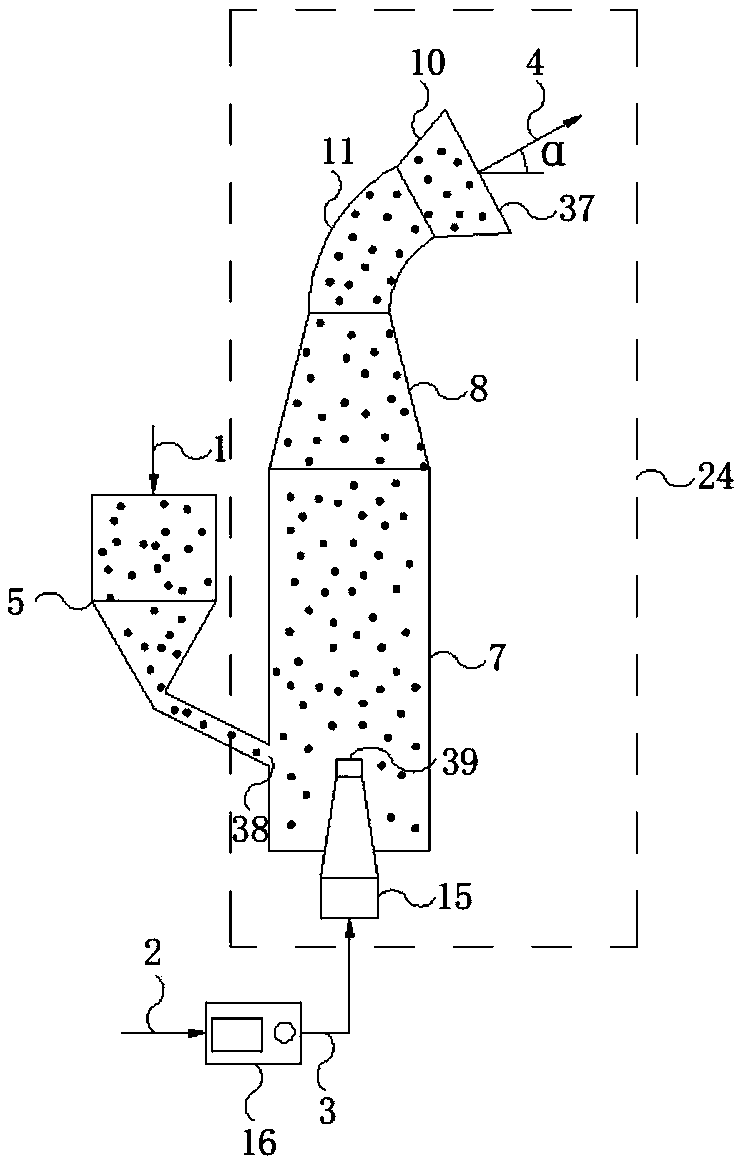

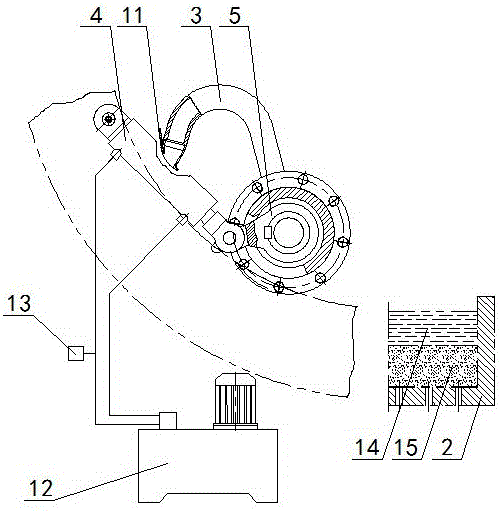

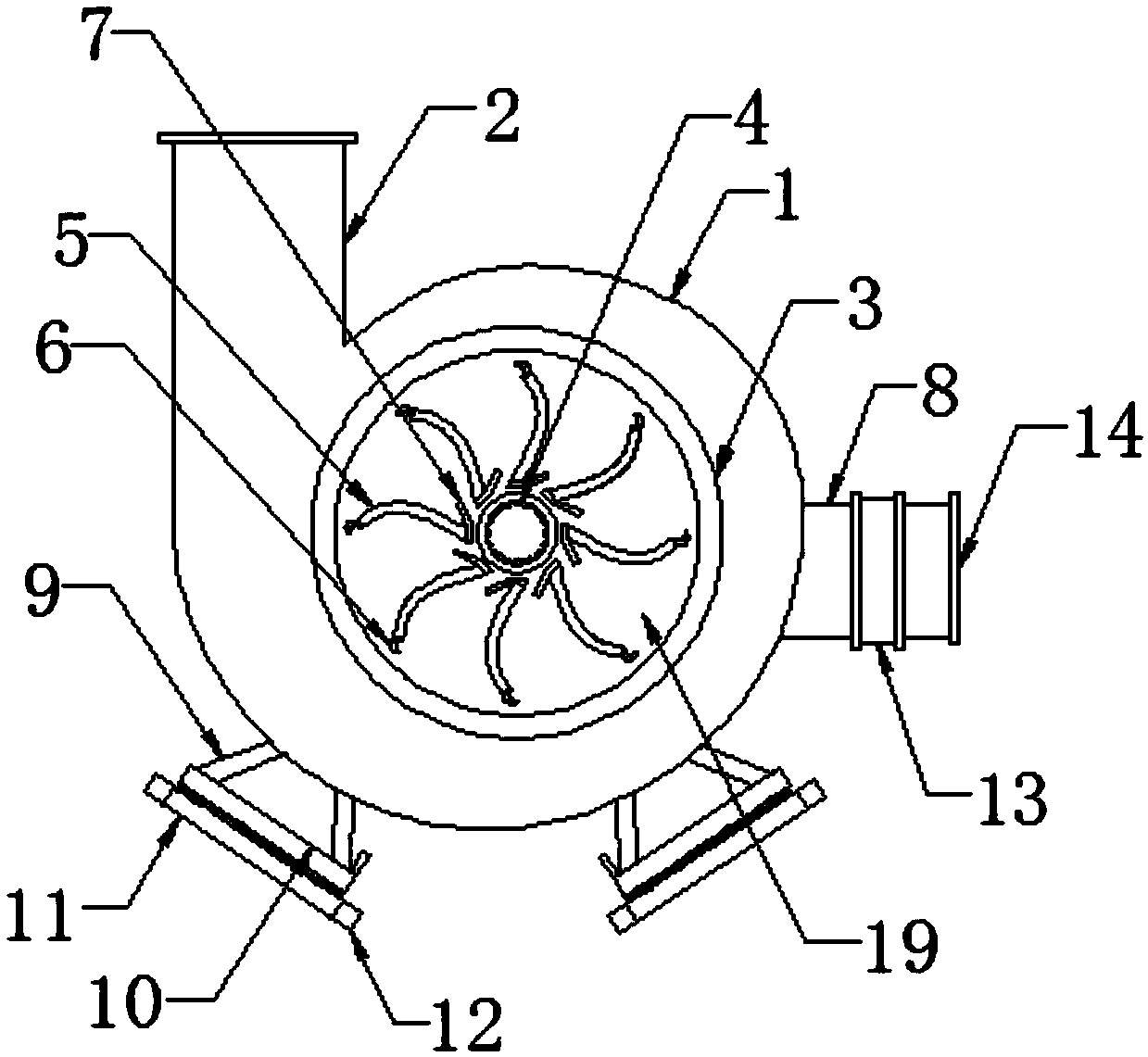

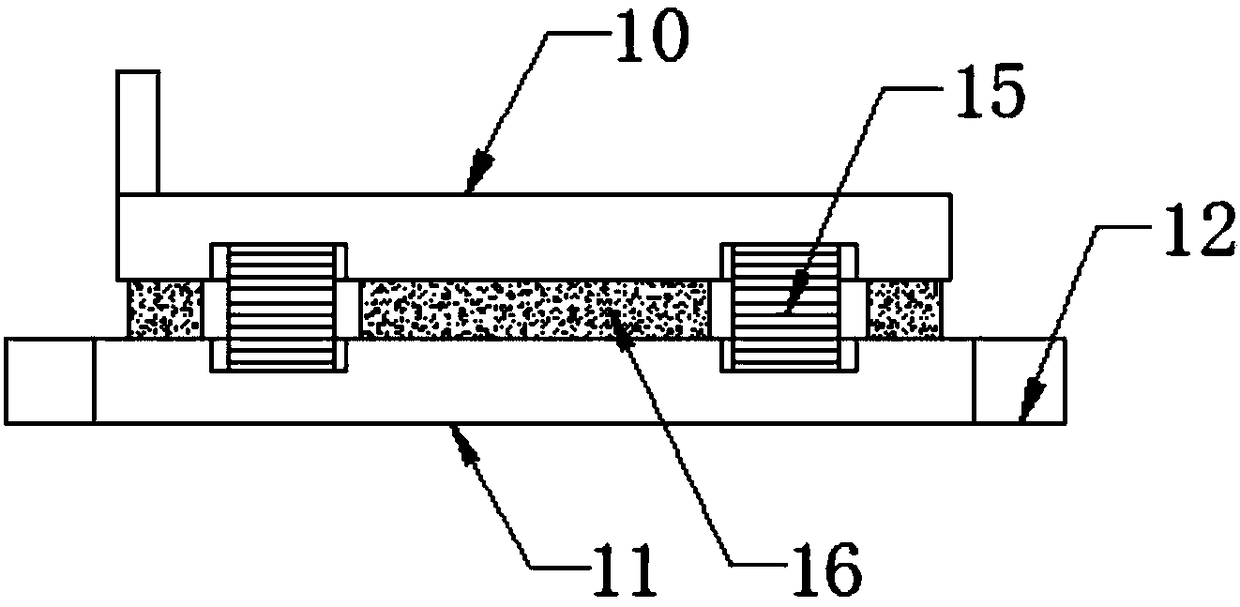

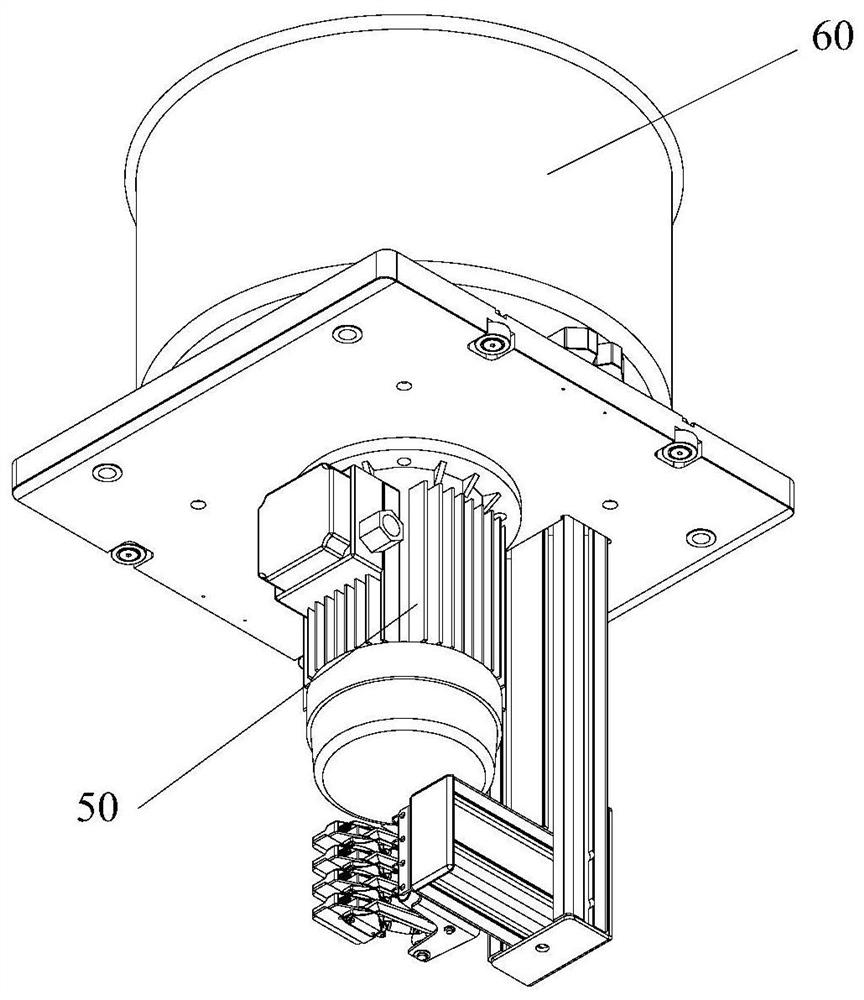

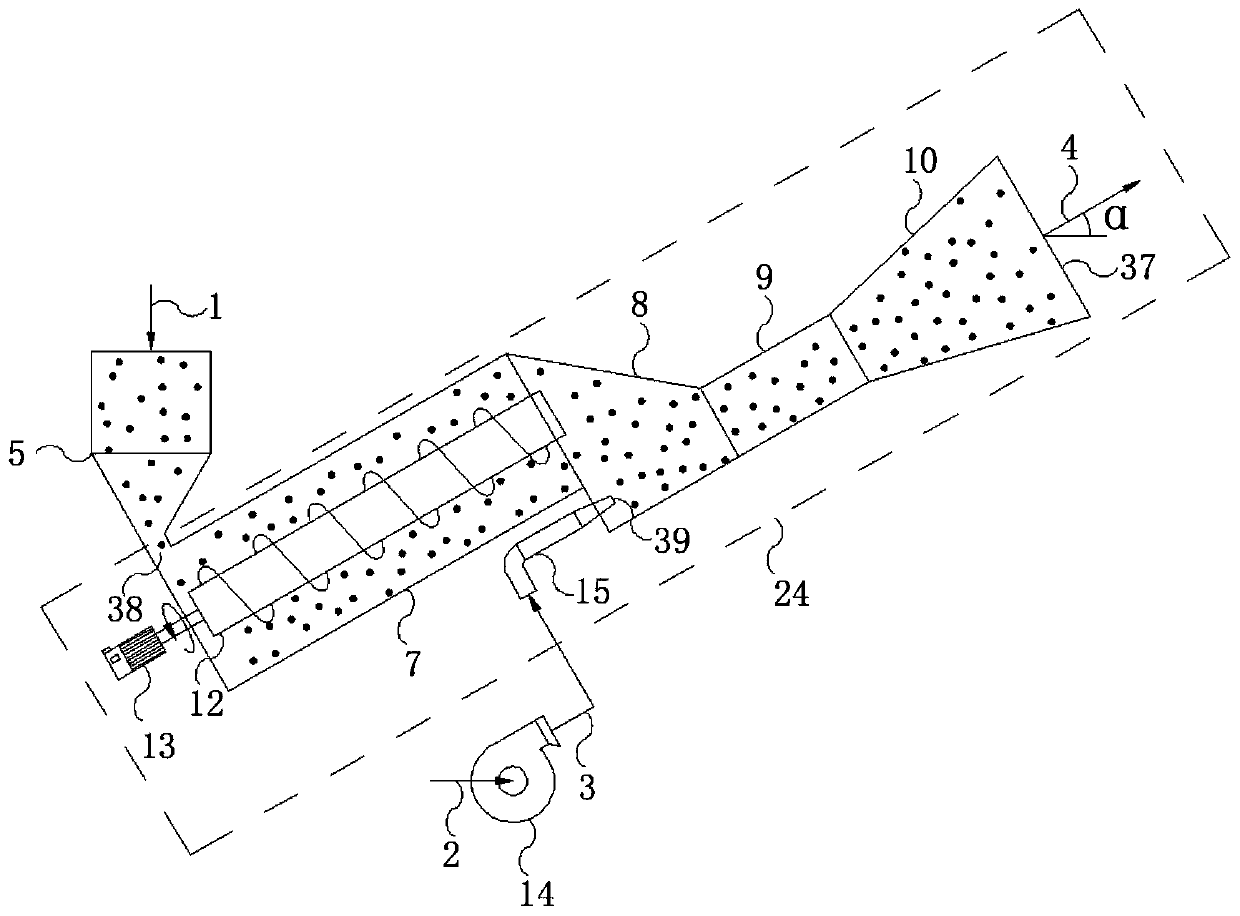

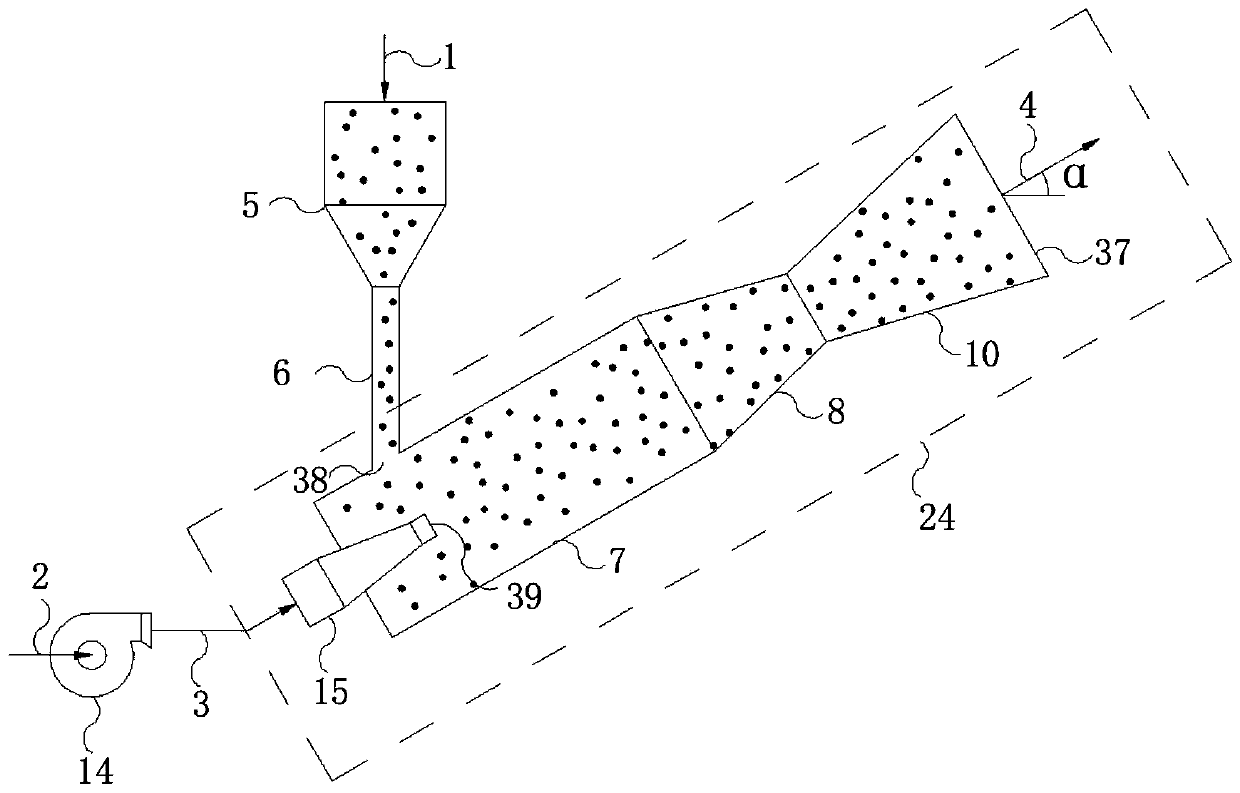

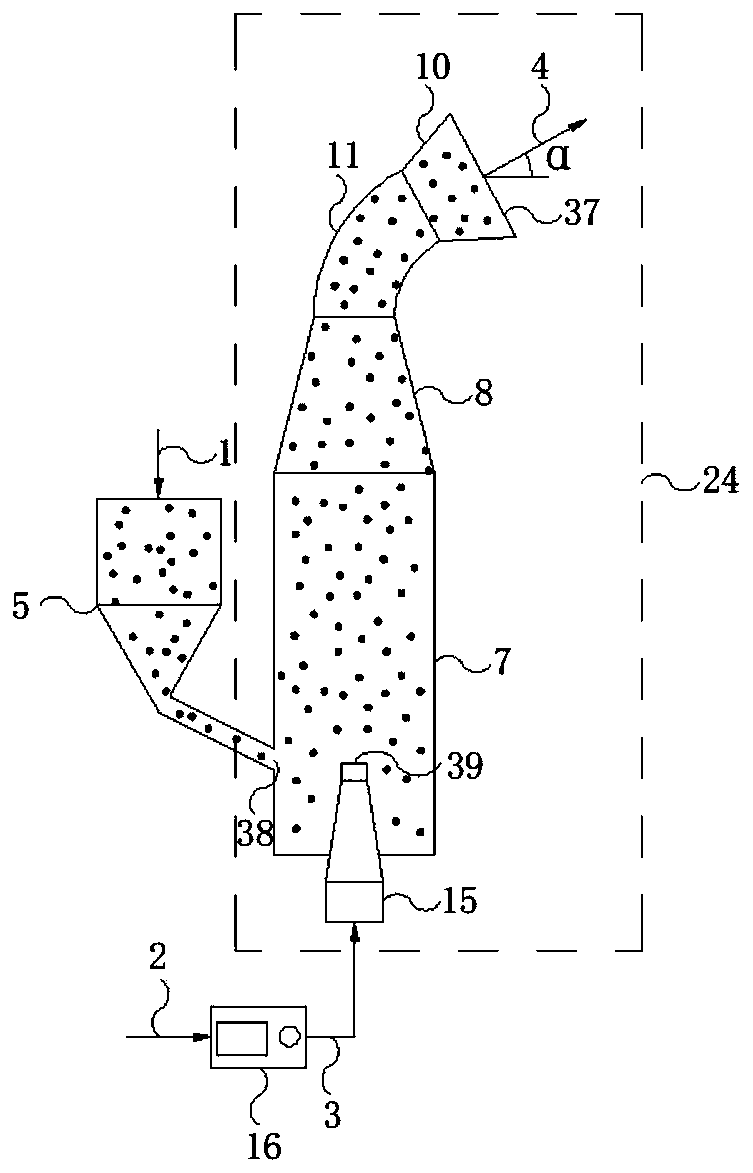

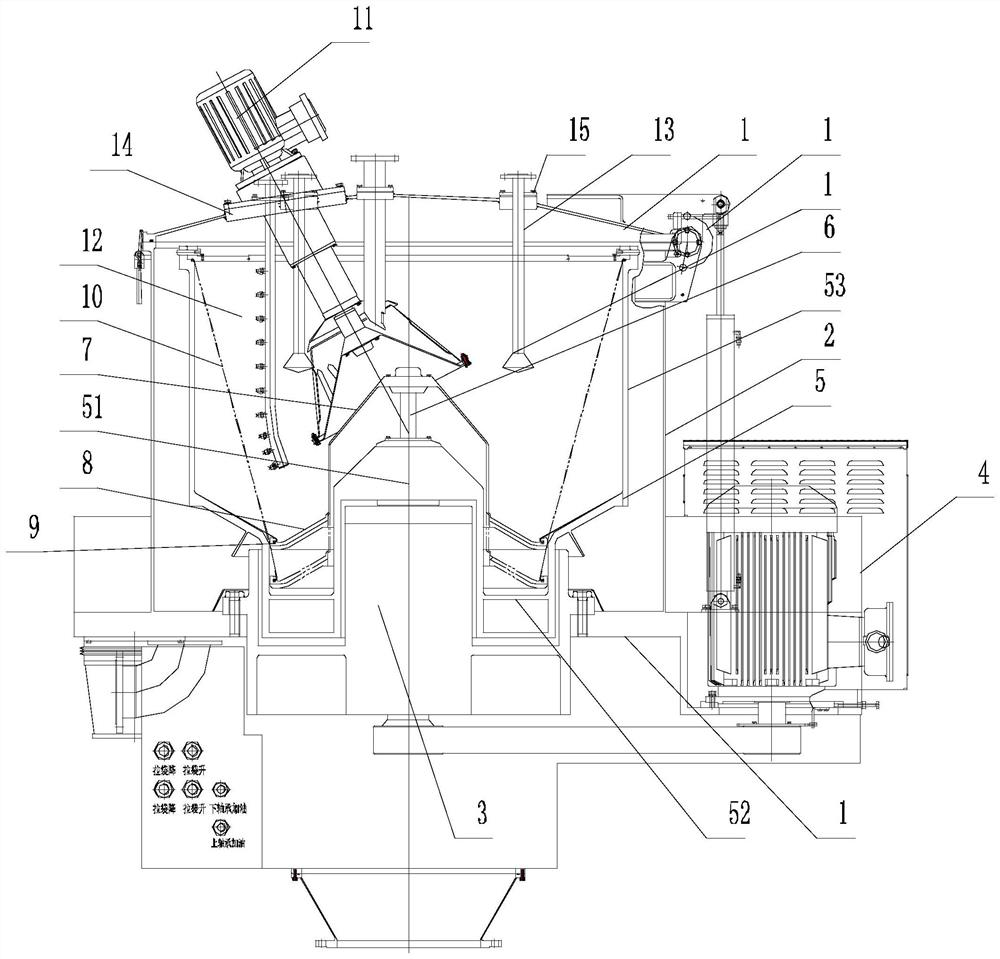

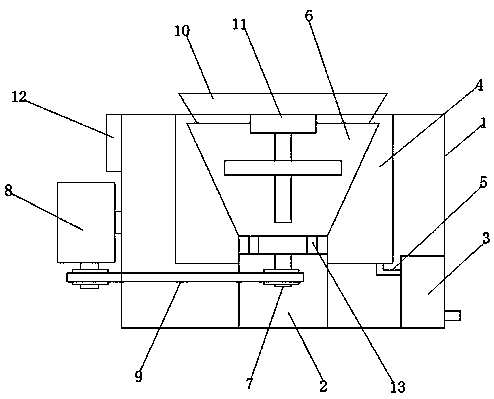

Granulating device and heat recovery method for melted slag

ActiveCN109207659AGuaranteed centrifugal effectImprove crushing effectRecycling and recovery technologiesRecovery methodSlag

The invention relates to a granulating device and heat recovery method for melted slag. The heat recovery method comprises the following procedures: an air-powder flow production procedure: mixing powder with compressed air; a melted slag granulation procedure: jetting the produced air-powder flow to a melted slag flow to convert the melted slag flow into high-temperature granulated slag; and a melted slag powder returning procedure: returning fine-grain powder produced in the melted slag granulation procedure as powder for the air-powder flow production procedure to the air-powder flow production procedure for cyclic usage. According to the invention, high-speed air-powder flow is used as a granulating medium for granulation of the melted slag into high-temperature melted particles; fineslag particles obtained after screening of cooled granulated slag are used as the powder for the air-powder flow for cyclic usage; and waste heat in high-temperature granulation air after granulationof the melted slag is utilized. During granulation and heat recovery of a melting furnace, the energy loss of the granulating medium is low; impact kinetic energy on the melted slag is large; and on the premise of ensuring the granulation effect of the melted slag, the energy consumption of an air source can be reduced and high-grade hot air can be obtained.

Owner:TIANJIN UNIV

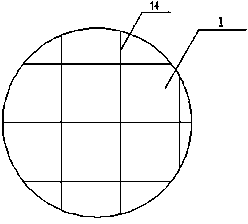

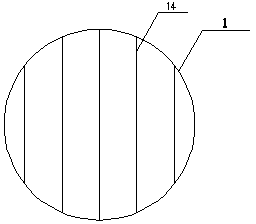

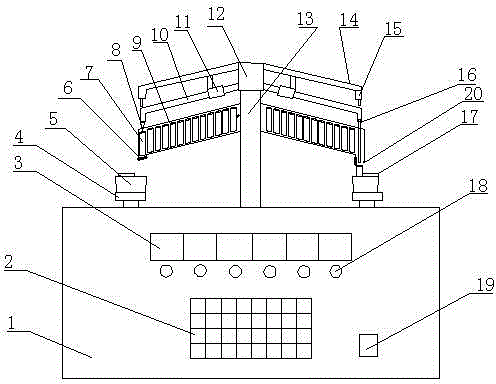

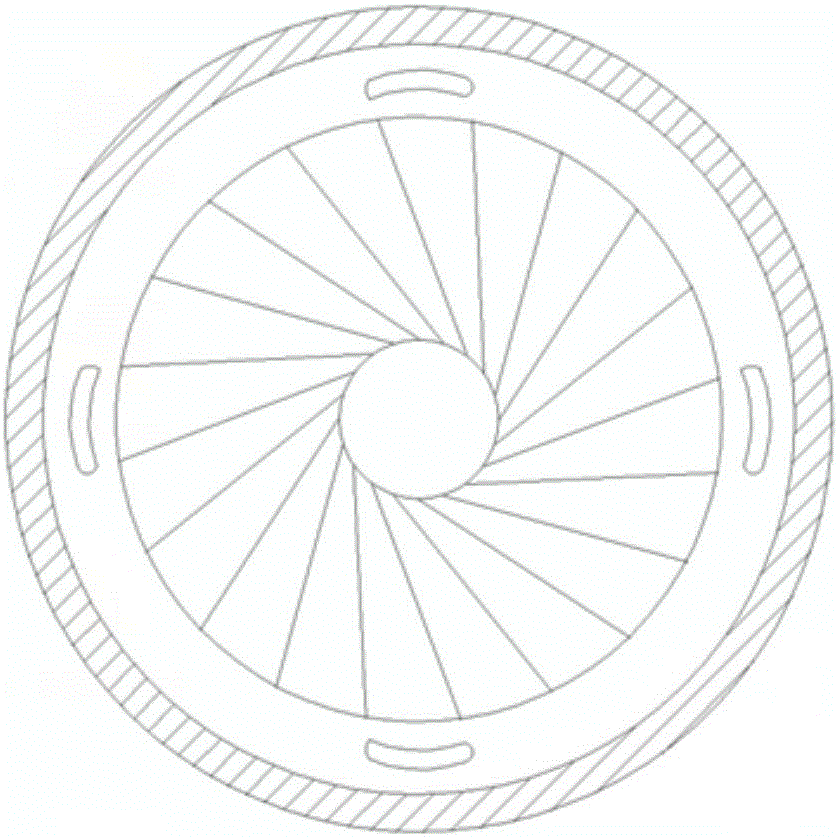

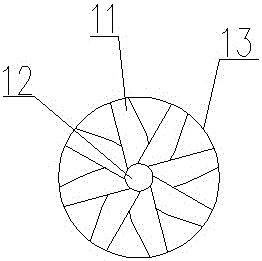

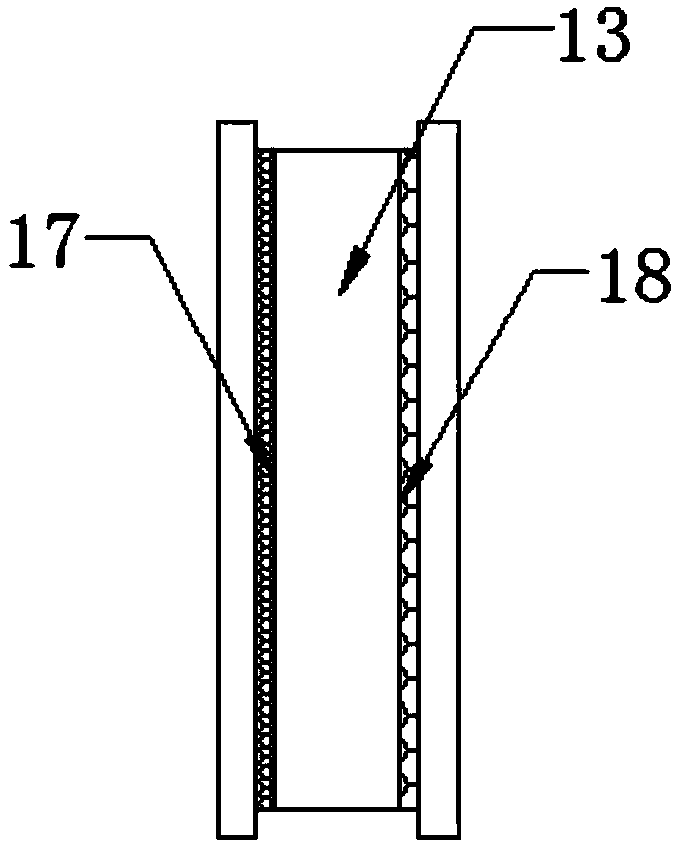

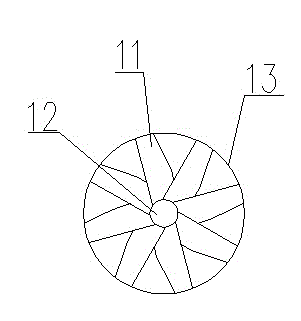

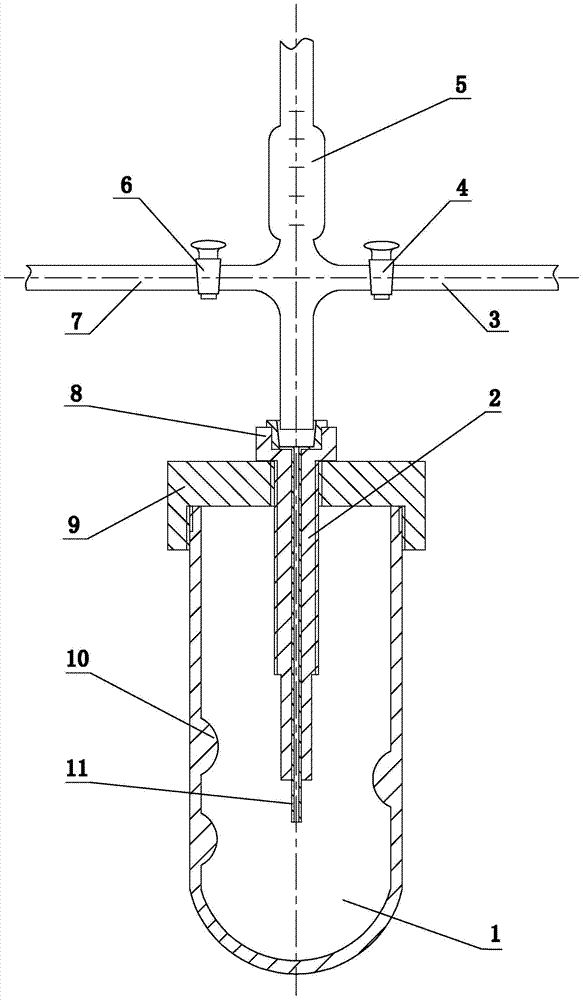

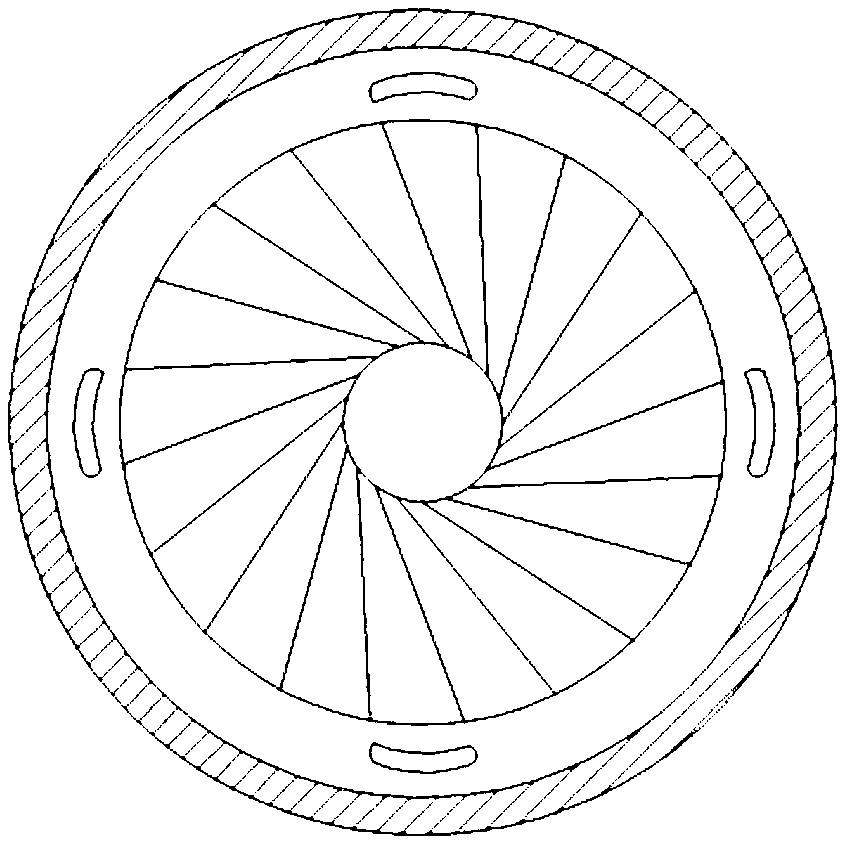

Cyclonic plate tower for thiourea production

ActiveCN106111026AImprove stabilityGuaranteed centrifugal effectOrganic chemistryLiquid-gas reaction processesThioureaSpray nozzle

The invention discloses a cyclonic plate tower for thiourea production, and belongs to the technical field of thiourea production equipment. The cyclonic plate tower comprises a tower body provided with an induced draft fan at the top, a liquid storage tank placed under the tower body and connected with the tower body. The cyclonic plate tower also comprises a cyclonic plate fixed inside the tower body, a spray nozzle arranged above the cyclonic plate and communicated with the liquid storage tank. The cyclonic plate tower is characterized in that the outer diameter of the cyclonic plate is smaller than the inner diameter of the tower body, and an overflow channel is formed in a cavity between the cyclonic plate and the tower body. The overflow pipes and the overflow grooves with overflow holes are omitted. The cyclonic plate tower is simple in structure, and convenient in installation and maintenance. After the overflow pipe is omitted, the airflow is more stable to avoid the occurrence of turbulence and to ensure that the centrifugal effect of the droplets in the airflow. As the overflow channel is of ring structure, even if some place is blocked by lime nitrogen slurry, the normal production will not be affected, maintenance times is reduced, production efficiency is improved, maintenance cost is saved and maintenance is facilitated.

Owner:HEBEI XINJI CHEM GRP

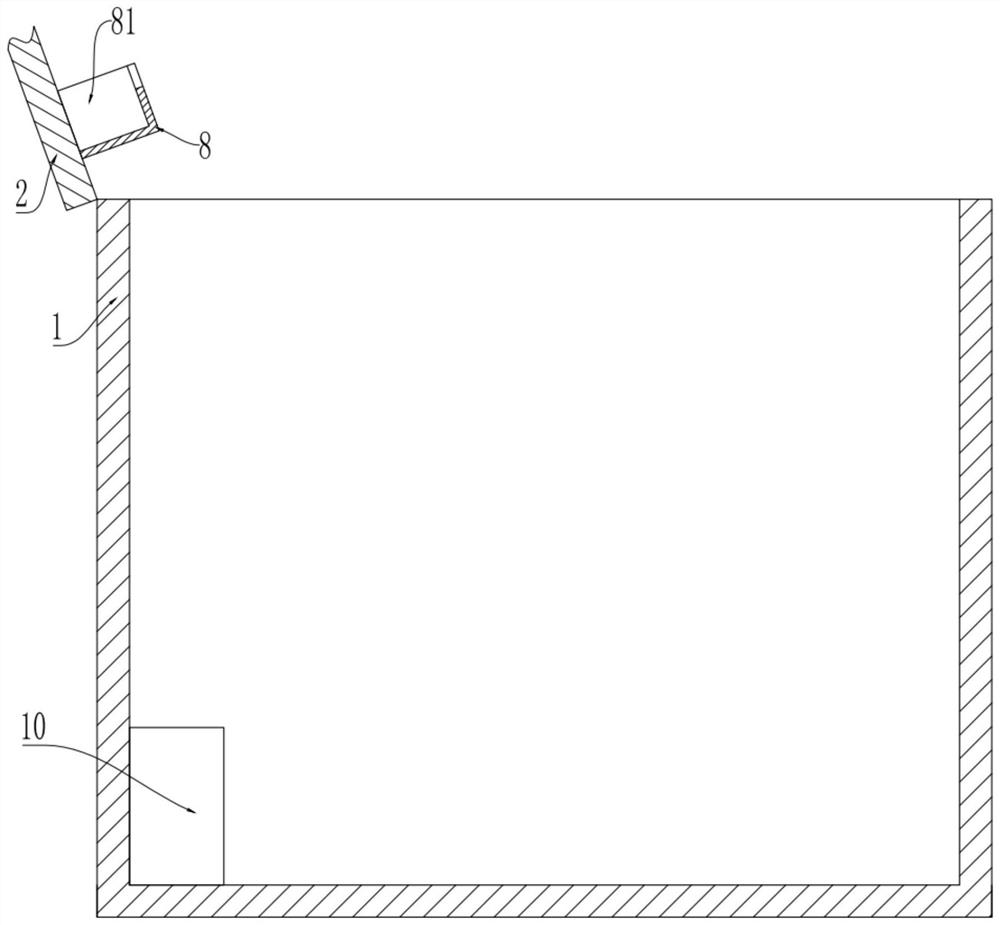

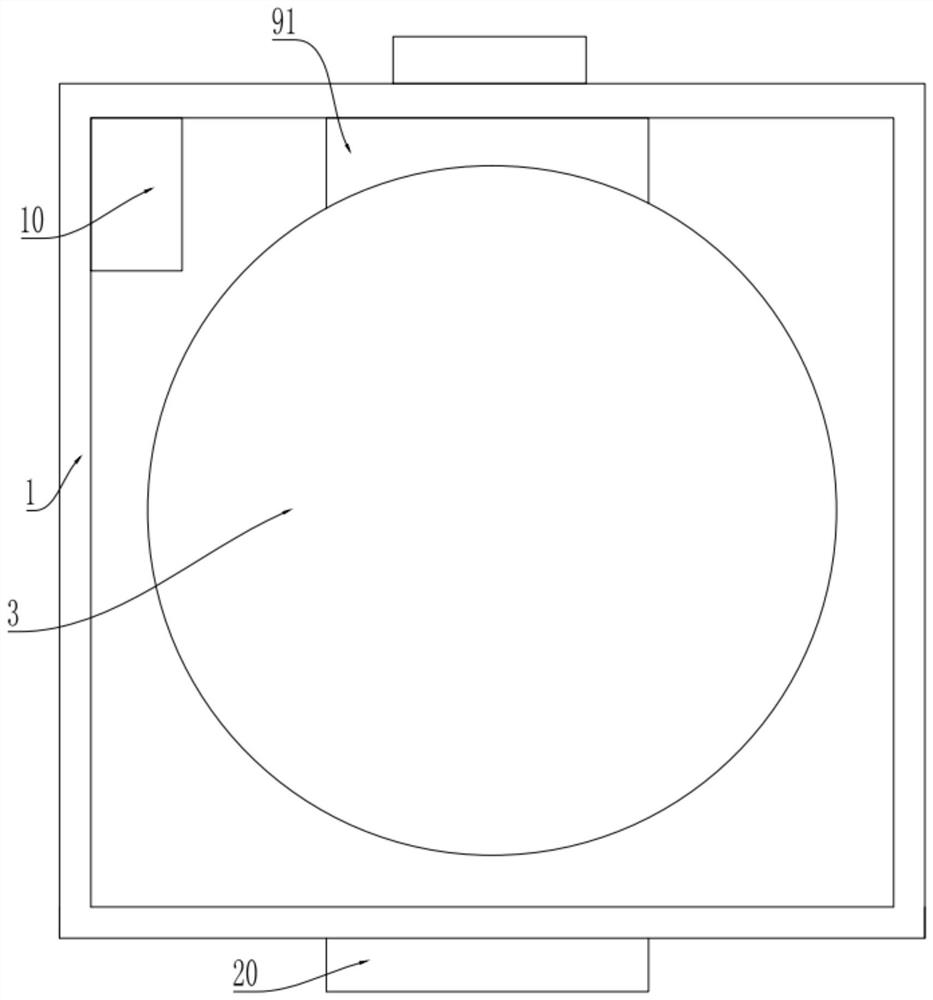

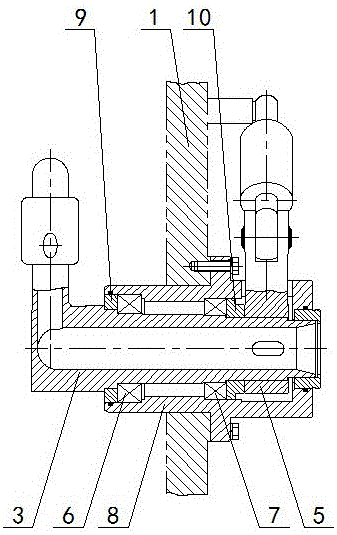

Liquid skimming device of scraper centrifugal machine

The invention discloses a liquid skimming device of a scraper centrifugal machine. The liquid skimming device comprises a machine cover (1), a rotating drum (2) is arranged in the machine cover (1), a liquid skimming pipe (3) penetrating through the machine cover (1) is arranged on the machine cover (1), the middle of the liquid skimming pipe (3) is movably connected with the machine cover (1), a swinging mechanism connected with the pipe skimming pipe (3) is arranged at the liquid discharging end of the pipe skimming pipe (3), and the liquid feeding end of the pipe skimming pipe (3) corresponds to an inner cavity in the rotating drum (2). The liquid skimming device has the advantages of being ingenious in structural design and reliable in using; after the liquid skimming device is adopted, light liquid can be led out, the conditions that liquid skimming is incomplete, and excessive filter cakes are skimmed out are further prevented, and the centrifugal effect and the product quality are guaranteed.

Owner:重庆江北机械有限责任公司

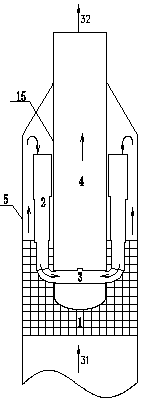

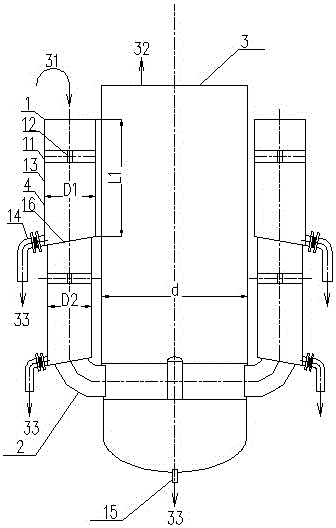

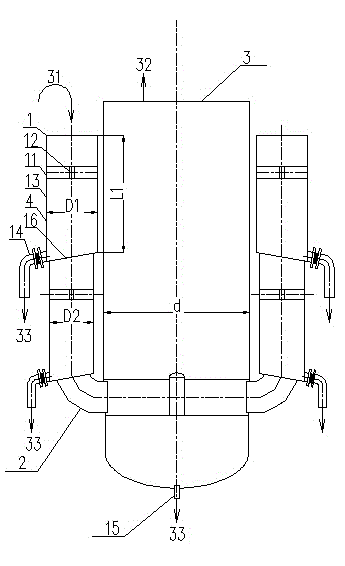

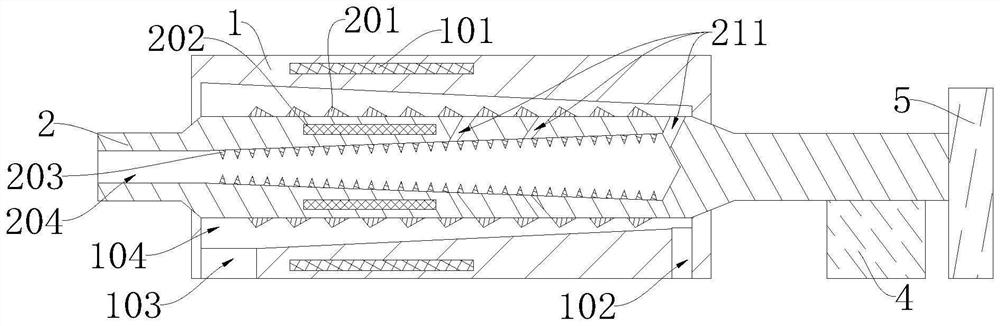

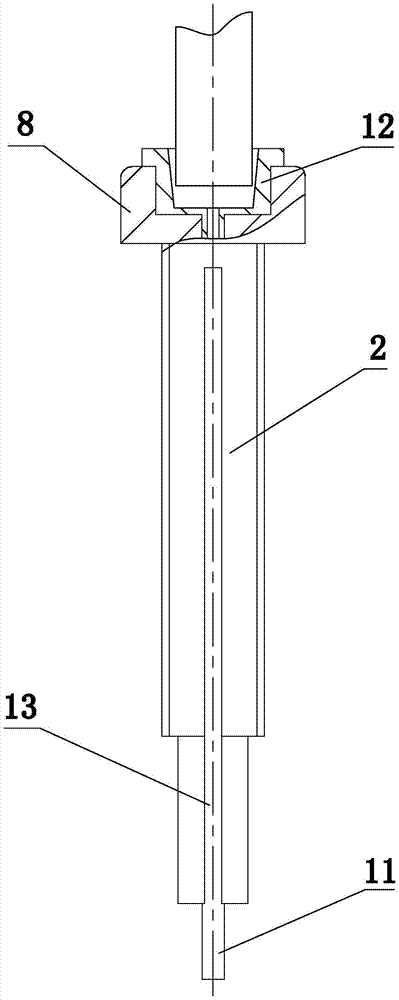

A kind of liquid removal method and liquid remover of multi-stage cyclone gas

InactiveCN104958959BReduce secondary entrainmentGuaranteed centrifugal effectDispersed particle separationCycloneFlue gas

A multi-stage cyclone liquid removal method and liquid remover, belonging to the field of gas-liquid separation technology, especially used for dehydration and liquid removal of flue gas discharged from wet flue gas desulfurization devices, including multi-stage cyclone, connecting cylinder, and exhaust cylinder . The multi-stage cyclone is composed of multi-stage cyclones connected in series up and down, and each stage of cyclone is composed of a cylinder body, a swirl part, and a liquid collection area. , In the centrifugal effective area, the liquid coalesced by the cyclones of each stage is led out in time, the gas enters the cyclone of the next stage, and finally enters the exhaust cylinder to be discharged.

Owner:QINGDAO JINGRUN PETROCHEM ENG

Centrifugal pump

InactiveCN108252916APrevent wanton flowReduce resistancePump componentsRadial flow pumpsAgricultural engineeringWater flow

The invention discloses a centrifugal pump which comprises a shell, a water outlet and a cover plate, wherein the water outlet is formed in one side of the shell, the cover plate is arranged in the shell, a connecting axle sleeve is arranged at the center of the cover plate, a plurality of arc blades are uniformly arranged at two sides of the cover plate, an arc head is fixed at one end of each ofthe arc blades, a damping mounting seat mechanism is connected to two sides of the bottom of the shell by two pairs of support rods which are hinged, a water inlet is formed in the other side of theshell, and a filtering mechanism is arranged at one side of the water inlet. According to the scheme, an arc water guide plate arranged at one end of the arc blade can guide water, so as to prevent water flowing to the connecting sleeve from flowing without restraint to reduce the centrifugal strength, and the design of an annular water blowing plate can reduce resistance of the cover plate to water after entering the shell, so as to improve the centrifugal efficiency; and due to the design of the damping mounting seat mechanism, the mounting angle can be changed flexibly according to mountingarea, so as to extent the use scope.

Owner:湖州诺诚低温设备有限公司

Multistage cyclone gas liquid removal method and liquid removal apparatus

InactiveCN104958959AReduce secondary entrainmentGuaranteed centrifugal effectDispersed particle separationCycloneFlue gas

The invention relates to a multistage cyclone gas liquid removal method and a liquid removal apparatus, and belongs to the technical field of gas-liquid separation. The method and the apparatus are especially used for dehydration and liquid removal of flue gas discharged from a wet flue gas desulphurization device, and the apparatus comprises a multistage cyclone, a connection cylinder and a gas discharge cylinder. The multistage cyclone is composed of multiple stages of up-and-down serially connected cyclones, every stage of the cyclones is composed of a cylinder body, a cyclone part and a liquid influx zone, the cyclone part is arranged in the center of the flue gas cylinder body of every stage of the cyclones, a liquid conglomerating from all the cyclones is timely leaded out in a centrifugal effective zone, and a gas enters a next stage of the cyclone, finally enters the gas discharge cylinder, and is discharged.

Owner:QINGDAO JINGRUN PETROCHEM ENG

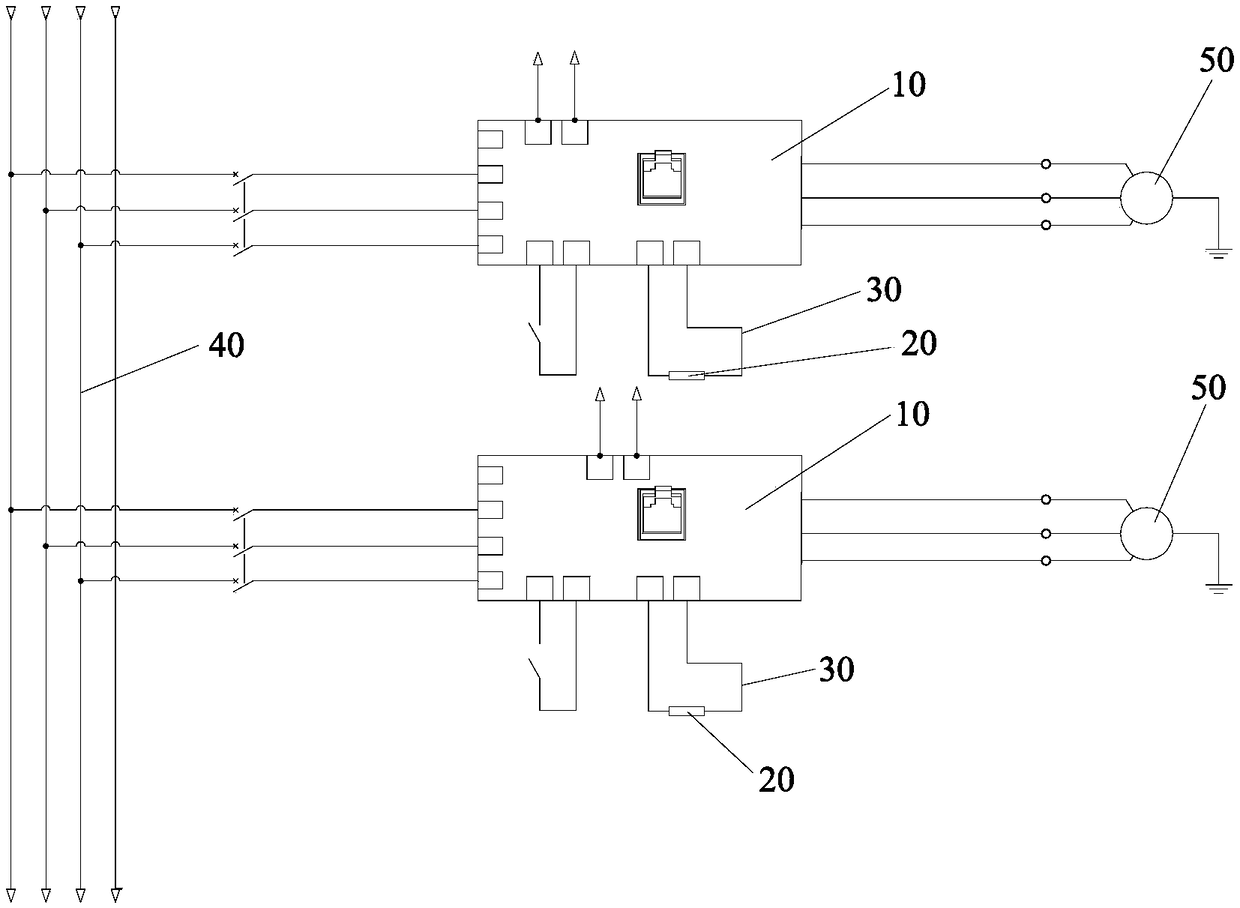

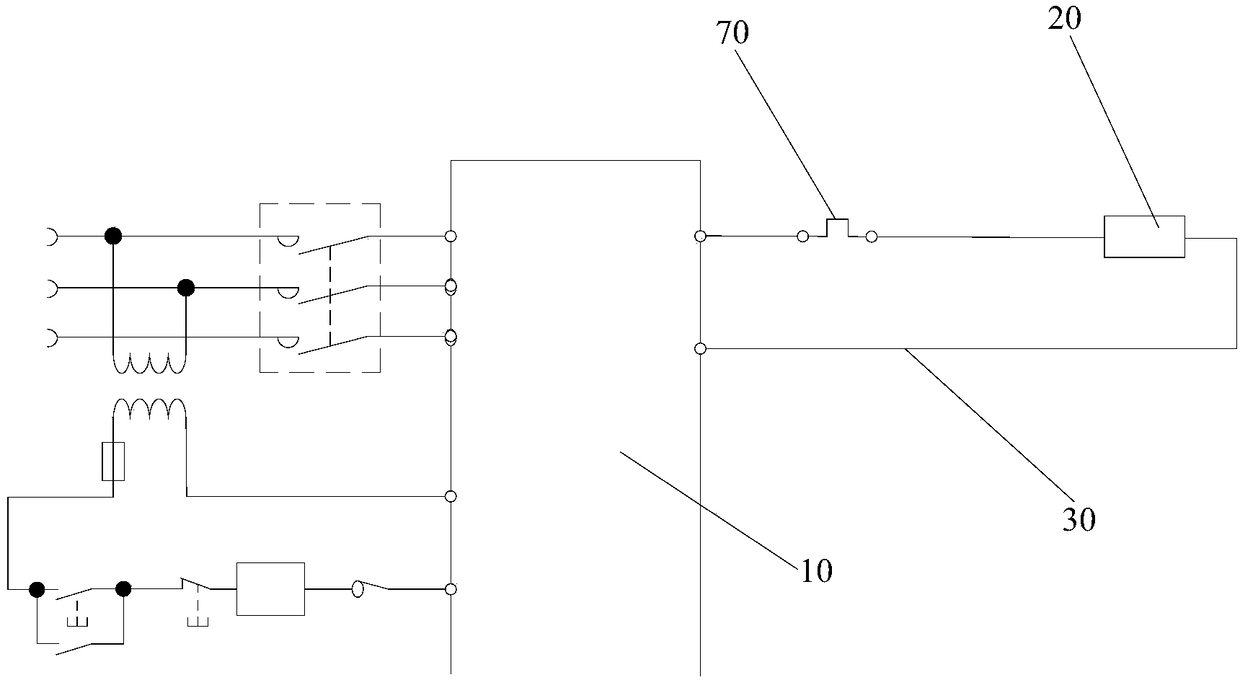

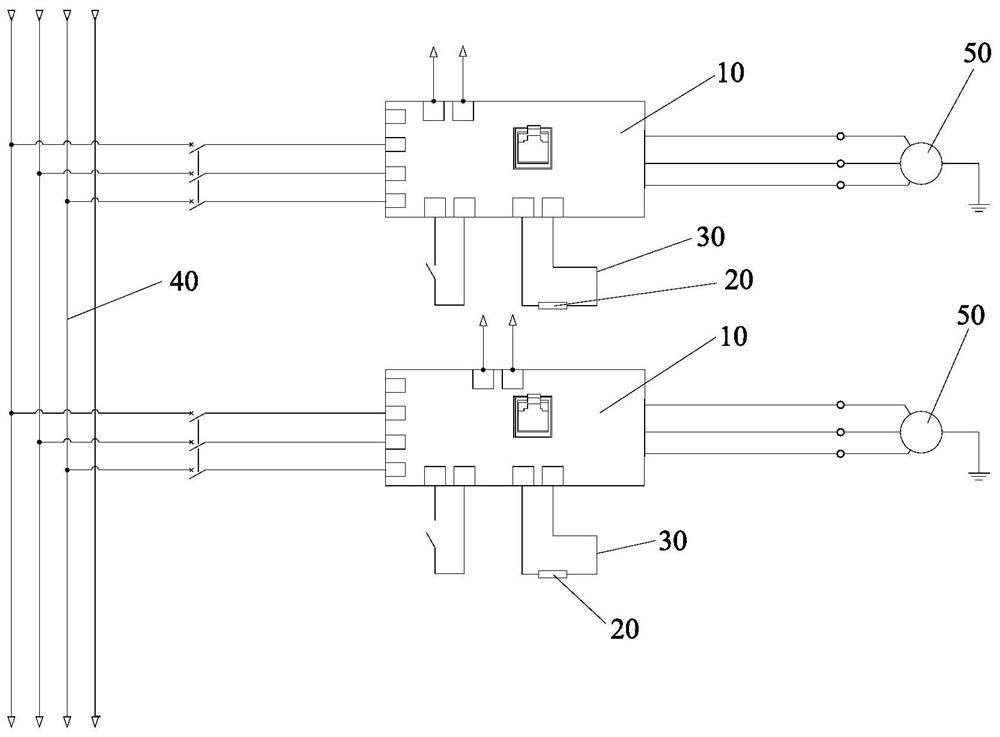

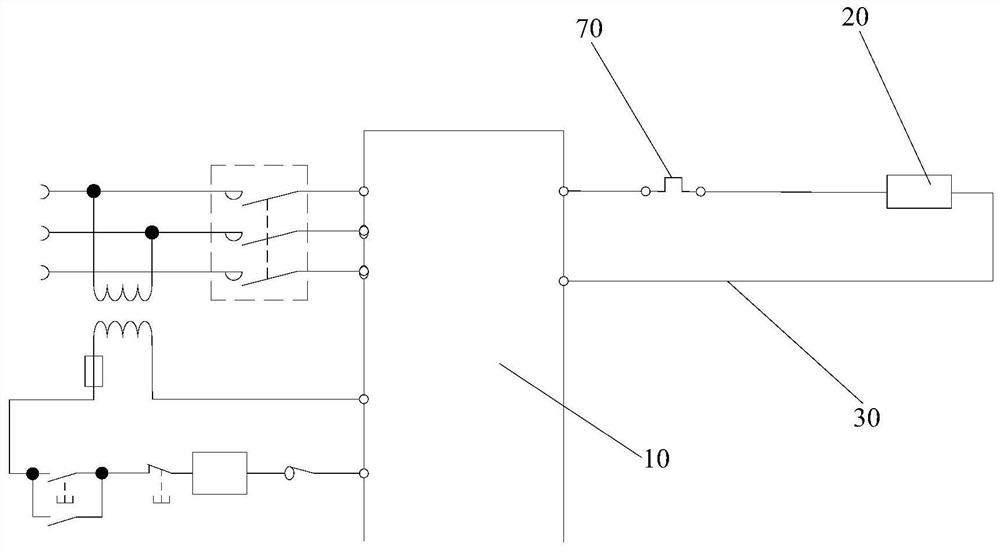

Brake control system for centrifugation barrel for dialyzer and centrifugation device for dialyzer

The invention provides a brake control system for a centrifugation barrel for a dialyzer and a centrifugation device for the dialyzer. The brake control system comprises control sub-systems. Each control sub-system comprises a frequency converter and an energy consumption brake module, wherein each frequency converter is electrically connected with a motor of the centrifugation barrel, and each energy consumption brake module is connected with the corresponding frequency converter. Each energy consumption brake module is used for consuming and / or shifting energy generated in the brake processof the corresponding motor. By means of the brake control system, the problems that in the prior art, a mechanical brake device is complex in structure and prone to mechanical abrasion, in addition, in the brake process, a centrifugation barrel is likely to shake, and the centrifugation effect of glue liquor is affected can be solved.

Owner:MAIDER MEDICAL IND EQUIP

Processing method of poured bean curd

PendingCN112471408AAvoid wastingIncrease productivityFood preservationCheese manufactureProcess engineeringSoya bean

The invention discloses a processing method of poured bean curd. The processing method comprises the following steps: step 1, storing raw materials and auxiliary materials; step 2, soaking soybeans: taking soybean raw materials, cleaning the soybean raw materials with normal-temperature water, and soaking the cleaned soybean raw materials for 8-14 hours; step III, performing grinding to obtain soybean milk: draining the soaked soybean raw materials, transferring the drained soybean raw materials to grinding equipment, and performing grinding to obtain soybean paste; 4, separation: taking the soybean paste, and carrying out centrifugal filtration through centrifugal equipment to obtain a semi-finished product; step 5, boiling the soybean milk: taking the semi-finished product, and cooking the semi-finished product for 5-6 minutes in a 104-108 DEG C temperature environment to obtain the soybean milk; step 6, burdening: weighing a gypsum lactone coagulator auxiliary material accounting for 0.29-0.31% of the weight of the soybean raw material for later use; and step 7, pouring: transferring the soybean milk into pouring equipment, dissolving the weighed gypsum lactone coagulator auxiliary materials in water according to a mass ratio of 1:5, adding the dissolved gypsum lactone coagulator auxiliary materials into the soybean milk, and performing pouring operation for 3-7min so as toobtain the poured bean curd. The production efficiency is high, the yield is stable, and raw material waste can be effectively avoided.

Owner:福州颐玖叁叁豆制品有限公司

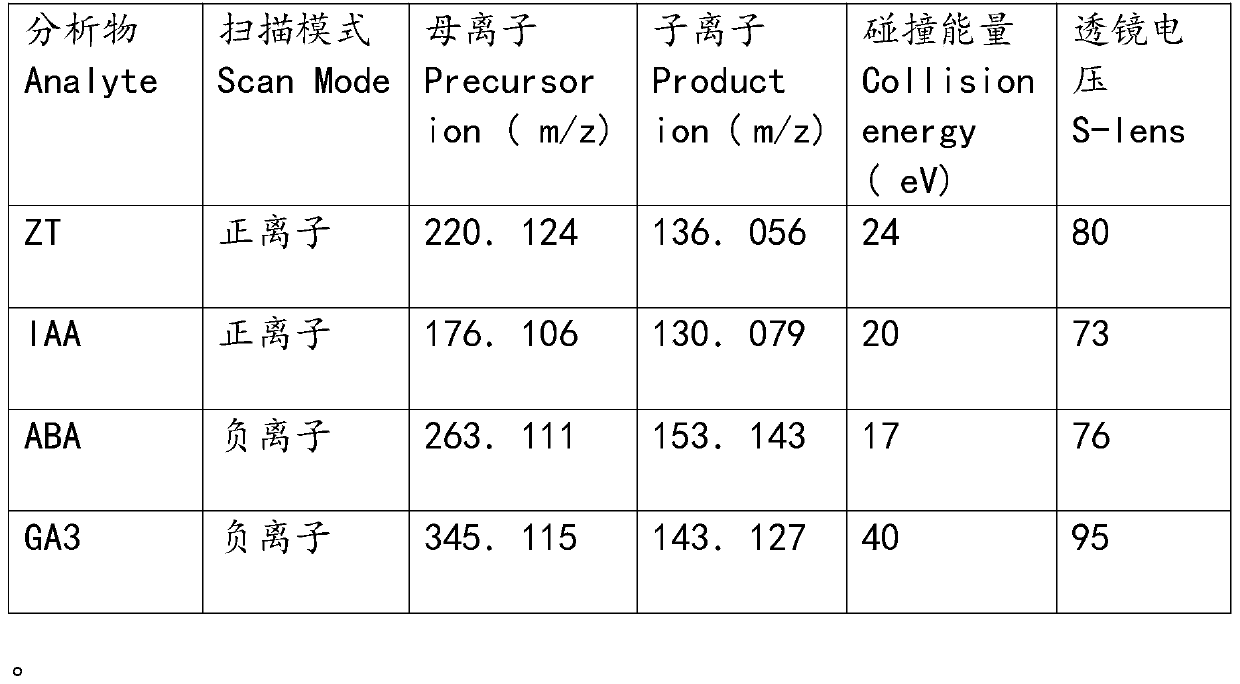

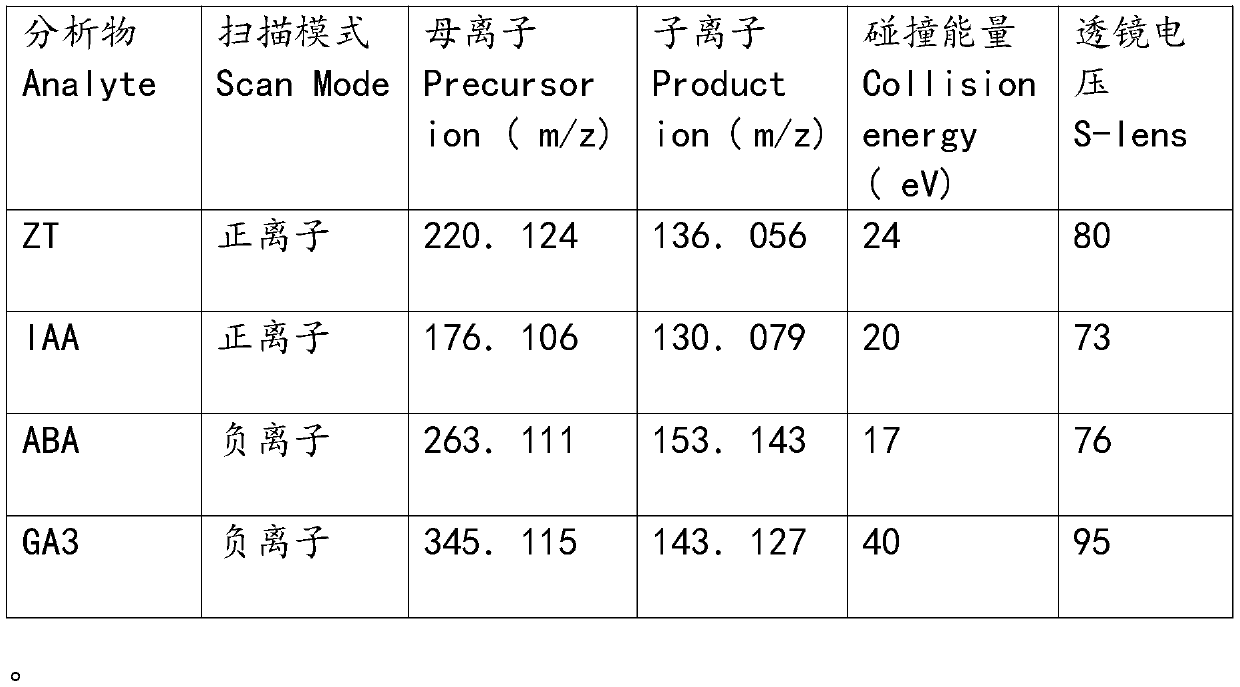

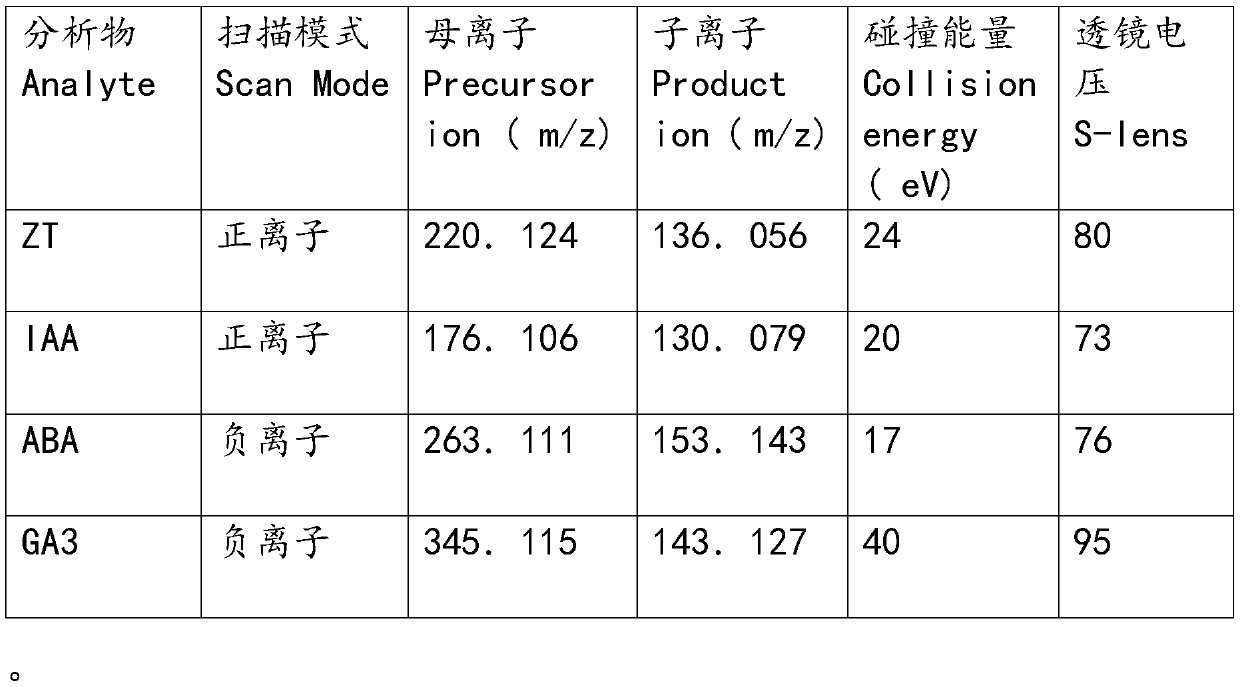

Method for detecting endogenous hormones in pinus massoniana branches

The invention relates to the field of determination of plant endogenous hormones, in particular to a method for detecting endogenous hormones in pinus massoniana branches. The method comprises the following steps: putting pinus massoniana branches into liquid nitrogen, grinding the branches into powder, and adding methanol to obtain a mixed solution; adding vitamin C into the mixed solution, keeping the solution standing in an environment of 3-5 DEG C, and carrying out centrifuging to obtain a precipitate; then adding methanol into the precipitate, then carrying out centrifuging, taking supernatant, filtering the supernatant through a polyvinylpyrrolidone (PVPP) column and a diethylaminoethyl cross-linked dextran gel column in sequence, and taking a filtrate; and finally, blow-drying the filtrate, adding analytically pure methanol to a constant volume, collecting the constant volume solution by using a disposable syringe, carrying out filtering by using a 0.22 <mu>m microporous filtermembrane, and analyzing and detecting by using high performance liquid chromatography-mass spectrometry to obtain the content of endogenous hormones in the pinus massoniana branches. The method is simple in procedure steps, the recovery rate of the detected endogenous hormone is high, and a detection result is accurate.

Owner:GUIZHOU MINZU UNIV

Brake control system of centrifugal cylinder for dialyzer and centrifugal device for dialyzer

The invention provides a brake control system for a centrifugation barrel for a dialyzer and a centrifugation device for the dialyzer. The brake control system comprises control sub-systems. Each control sub-system comprises a frequency converter and an energy consumption brake module, wherein each frequency converter is electrically connected with a motor of the centrifugation barrel, and each energy consumption brake module is connected with the corresponding frequency converter. Each energy consumption brake module is used for consuming and / or shifting energy generated in the brake processof the corresponding motor. By means of the brake control system, the problems that in the prior art, a mechanical brake device is complex in structure and prone to mechanical abrasion, in addition, in the brake process, a centrifugation barrel is likely to shake, and the centrifugation effect of glue liquor is affected can be solved.

Owner:MAIDER MEDICAL IND EQUIP

Processing method of hard bean curd

PendingCN112450384AAvoid wastingIncrease productivityCheese manufactureFood scienceProcess engineeringSoya bean

The invention discloses a processing method of hard bean curd. The processing method comprises the following steps: 1, raw materials and auxiliary materials are prepared, specifically, soybean raw materials and magnesium chloride auxiliary materials for implementing production license management are prepared; 2, soybeans are soaked, specifically, soybean raw materials are taken and cleaned with normal-temperature water, and then the cleaned soybean raw materials are soaked for 8 h-14 h; 3, grinding is conducted, specifically, the soaked soybean raw materials are drained, transferred to grinding equipment and ground to obtain soybean paste; 4, separation is conducted, specifically, the soybean paste is taken and subjected to centrifugal filtration through centrifugal equipment to obtain a semi-finished product; 5, boiling is conducted, specifically, the semi-finished product is taken and boiled for 5 min-6 min in a 104 DEG C-108 DEG C temperature environment to obtain soybean milk; 6, burdening is conducted, specifically, magnesium chloride auxiliary materials accounting for 0.29-0.31 wt% of the soybean raw materials are weighed for later use; and 7, marinating is conducted, specifically, the soybean milk is transferred into marinating equipment, the weighed magnesium chloride auxiliary materials are dissolved into water according to a mass ratio of 1:5, the obtained solution isadded into the soybean milk, and marinating is conducted for 18 min-22 min so as to obtain the hard bean curd. The production efficiency is high, the yield is stable, and raw material waste can be effectively avoided.

Owner:福州颐玖叁叁豆制品有限公司

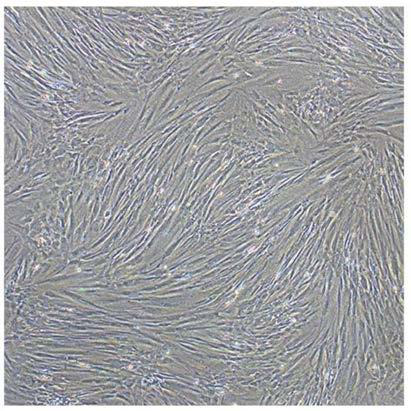

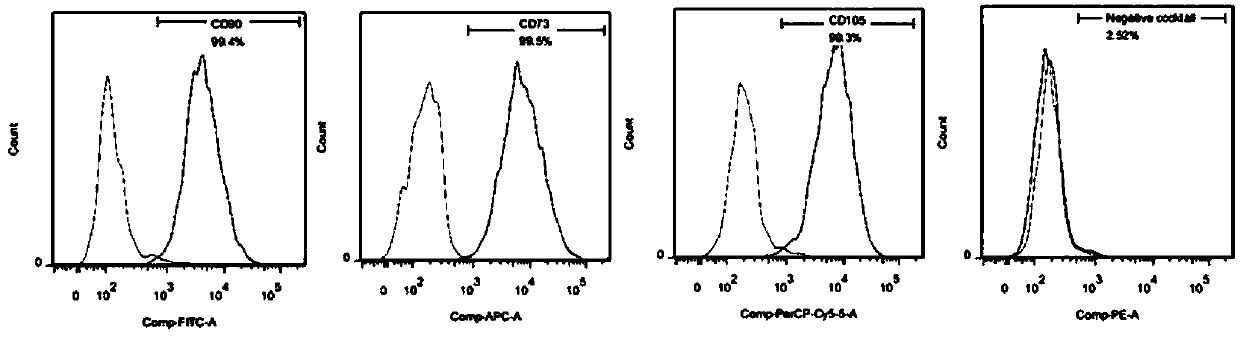

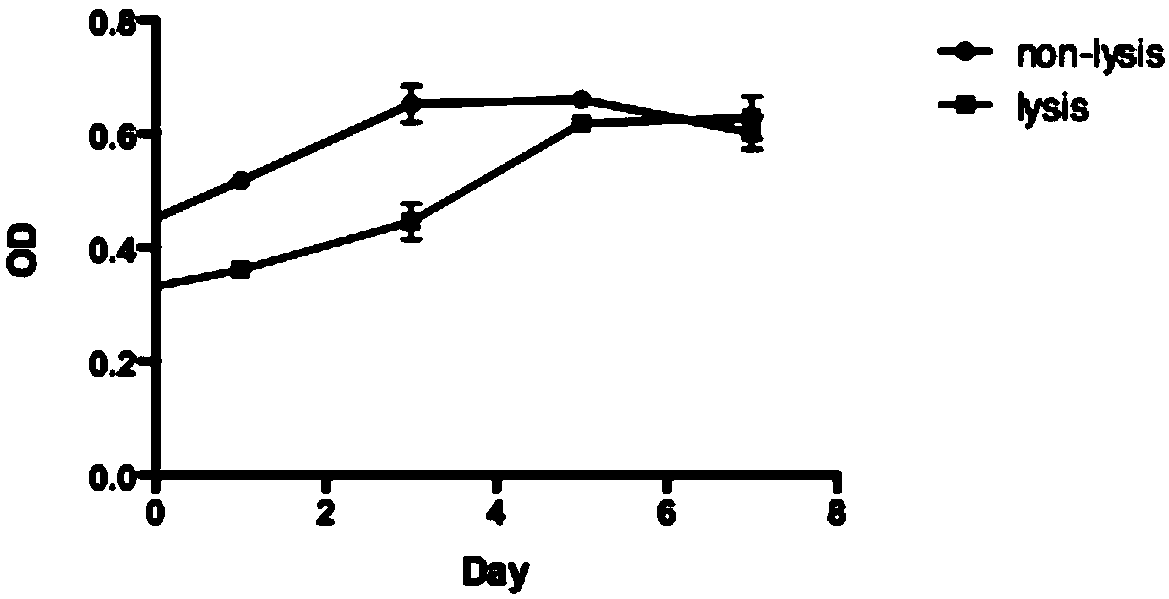

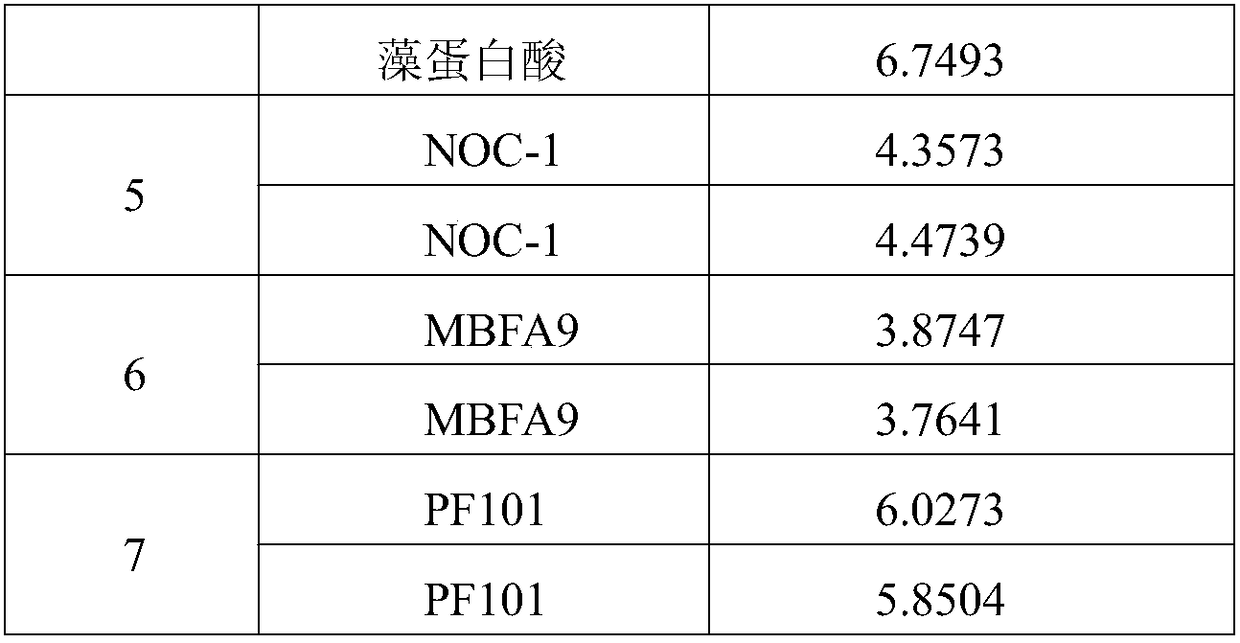

Method for highly efficient separation of adipose mesenchymal stem cells from adipose extracts

InactiveCN109554339AIncrease acquisition rateGood conditionCell dissociation methodsSkeletal/connective tissue cellsMesenchymal stem cellBrown adipose tissue

The invention relates to a method for highly efficient separation of adipose mesenchymal stem cells from adipose extracts, wherein the method comprises the following steps: step 1, obtaining of preadipocytes: adding a collagenase solution to an adipose tissue, shaking to obtain a mixed solution, adding a culture medium to the mixed solution, to obtain a secondary mixed solution, centrifuging the secondary mixed solution, and collecting bottom cells to obtain the preadipocytes; and step 2, obtaining of the adipose mesenchymal stem cells: resuspensing the preadipocytes obtained in the step 1 with a culture medium to obtain a cell resuspension, filtering the cell resuspension to remove impurities, to obtain a solution containing the adipose mesenchymal stem cells, and measuring the number ofcells in the solution containing the adipose mesenchymal stem cells per unit volume. The method for separation of the adipose mesenchymal stem cells from the adipose tissue is provided, wherein the method is simple in material obtaining and has quantitative steps and high repeatability.

Owner:PLASTIC SURGERY HOSPITAL CHINESE ACAD OF MEDICAL SCI

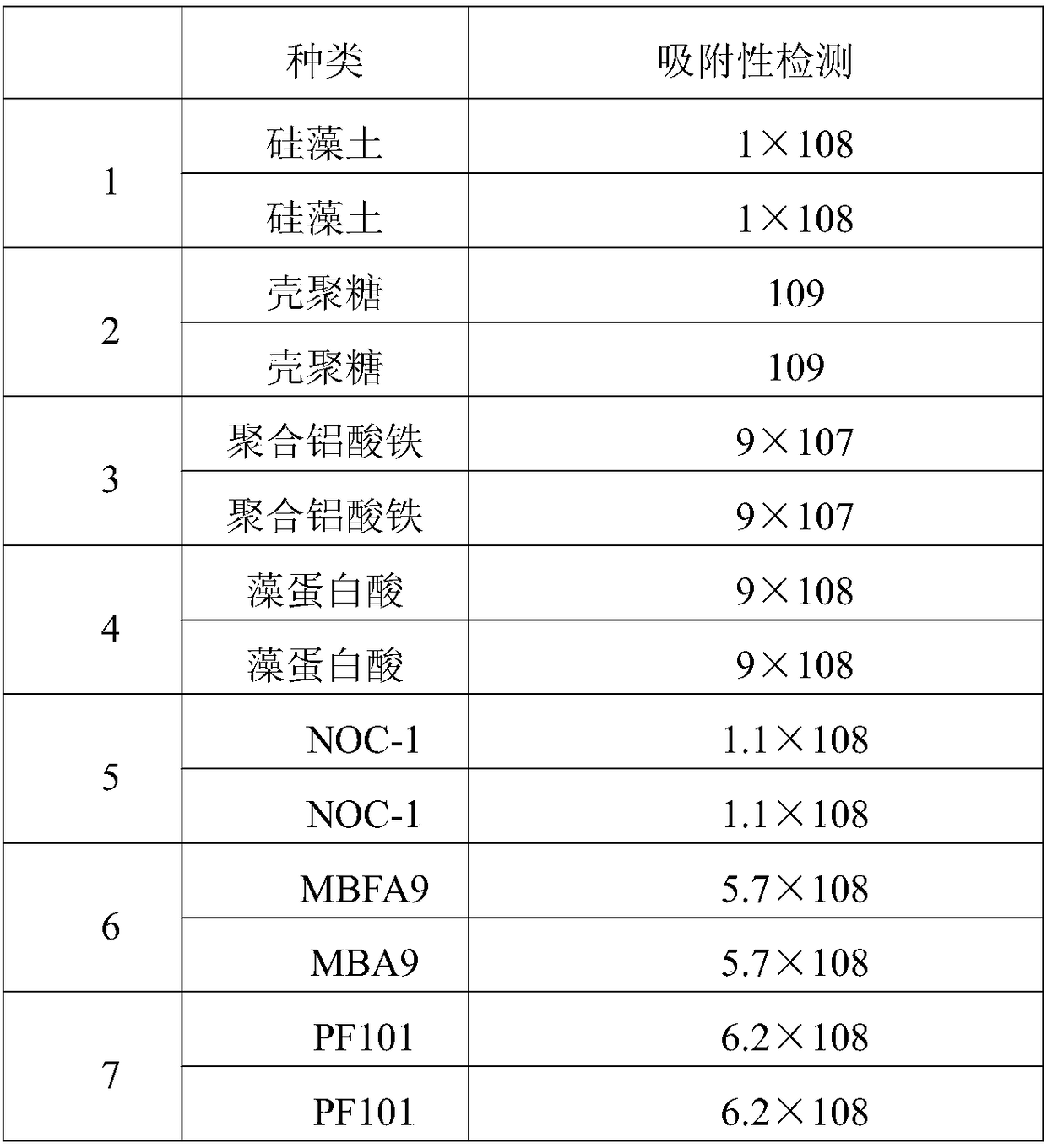

Composite bioflocculant for aquiculture water body purification and preparation method thereof

InactiveCN108298700APromote growthQuick purificationBiological water/sewage treatmentDiseaseWater quality

The invention relates to a composite bioflocculant for aquiculture water body purification. The composite bioflocculant is characterized by being prepared from mixed bacterial agents and mixed flocculants. A preparation method of the composite bioflocculant for the aquiculture water body purification comprises the following steps of (1) preparing the mixed bacterial agents; (2) preparing the mixedflocculants; (3) preparing the composite bioflocculant. The composite bioflocculant for the aquiculture water body purification has the advantages that the aquiculture water body can be fast purified; the purification effect is obvious; the safety is high; the microbial thalli can be easily adsorbed; the bacterial agent activity and the water body purification effect can be ensured; the water purification effect of the flocculant is shown; the organic matters settled at the bottom of the water body can be enabled to be timely decomposed by a great number of beneficial microbes; the growth ofthe aquatic organisms is indirectly promoted, so that the aquatic organism cannot easily catch diseases; the culture quality is improved.

Owner:天津实发中科百奥工业生物技术有限公司

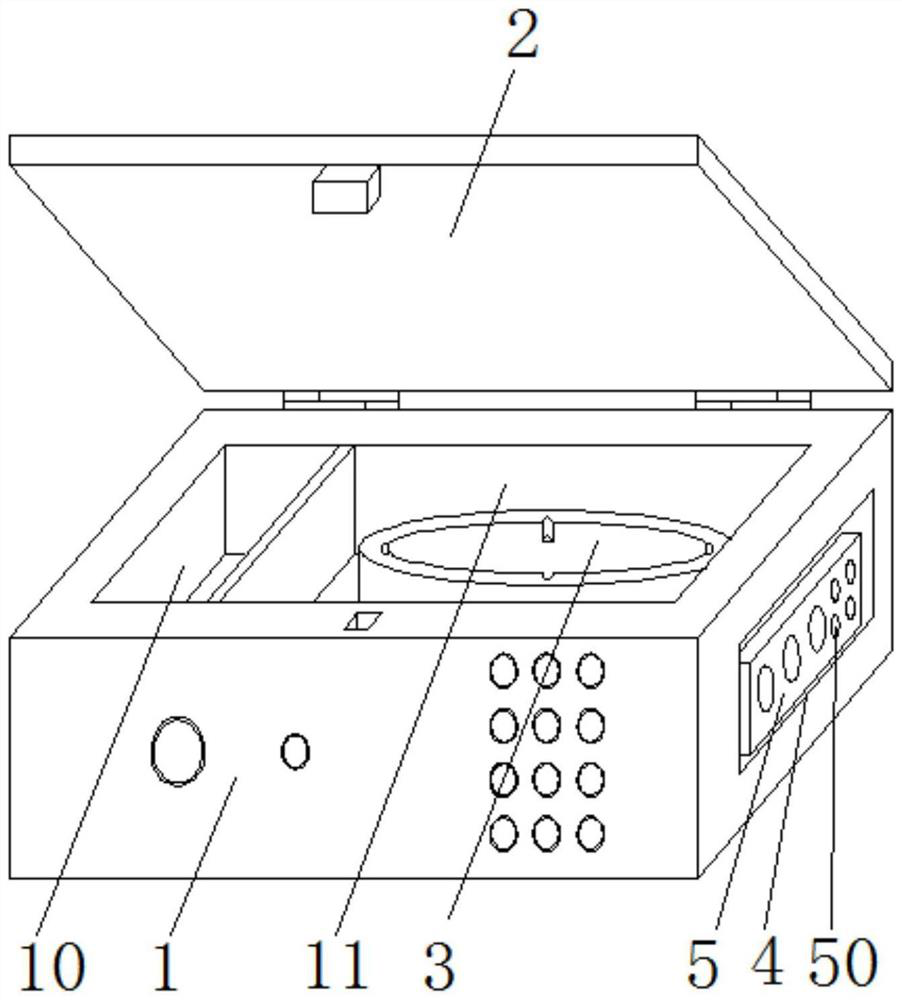

Centrifugal machine for experimental detection

The centrifugal machine for experimental detection comprises a box body and a box cover, the box cover is hinged to one side edge of the top end of the box body, a vertical centrifuge is fixedly embedded in the position, at the bottom end of a centrifugal cavity, of the box body, a rotating disc is fixedly connected to a rotating shaft of the centrifuge, and a groove is formed in the middle of the top end of the rotating disc; a plurality of limiting grooves are formed in the upper end of the inner side wall of the groove of the rotating disc, a centrifugal plate is fixedly clamped to the top end of the rotating disc, and a plurality of limiting blocks are fixedly connected to the upper ends of the peripheral side walls of the centrifugal plate. The device is ingenious in structural design, and through the limiting groove and the limiting block, the centrifugal plate can be clamped by the rotating disc conveniently; by inclining the centrifugal groove, the centrifugal tube can be stabilized, so that the centrifugal effect of centrifugal substances is guaranteed; the centrifugal plate is conveniently fixed again through the arc-shaped limiting ring, and meanwhile, the centrifugal plate can achieve rotary clamping of the arc-shaped limiting ring; and the limiting rods are inserted into the arc-shaped limiting holes, so that rotation of the arc-shaped limiting rings is facilitated.

Owner:安徽凡达工程科技有限公司

A granulation device and heat recovery method for molten slag

ActiveCN109207659BGuaranteed centrifugal effectImprove crushing effectRecycling and recovery technologiesGranulation procedureMolten slag

The invention relates to a granulating device and heat recovery method for melted slag. The heat recovery method comprises the following procedures: an air-powder flow production procedure: mixing powder with compressed air; a melted slag granulation procedure: jetting the produced air-powder flow to a melted slag flow to convert the melted slag flow into high-temperature granulated slag; and a melted slag powder returning procedure: returning fine-grain powder produced in the melted slag granulation procedure as powder for the air-powder flow production procedure to the air-powder flow production procedure for cyclic usage. According to the invention, high-speed air-powder flow is used as a granulating medium for granulation of the melted slag into high-temperature melted particles; fineslag particles obtained after screening of cooled granulated slag are used as the powder for the air-powder flow for cyclic usage; and waste heat in high-temperature granulation air after granulationof the melted slag is utilized. During granulation and heat recovery of a melting furnace, the energy loss of the granulating medium is low; impact kinetic energy on the melted slag is large; and on the premise of ensuring the granulation effect of the melted slag, the energy consumption of an air source can be reduced and high-grade hot air can be obtained.

Owner:TIANJIN UNIV

High-pressure water cutting and discharging centrifugal machine

PendingCN114682396AQuickly loosen and fall offExtend your lifeCentrifugesHigh pressure waterIndustrial water

The high-pressure water cutting discharging centrifugal machine comprises a machine base, a shell assembly, a main shaft assembly and a main power device are arranged on the machine base, a rotating drum is connected to a main shaft and comprises a rotating drum bottom, the rotating drum bottom is connected with a rotating drum wall through a plurality of rib plates, and a bag pulling driving rod movably penetrates through the main shaft; the machine base is provided with a bag pulling power device for driving the drawstring driving rod to move up and down, the upper end of the drawstring driving rod penetrates out of the bottom of the rotary drum, a cover-shaped bag pulling frame is arranged on the drawstring driving rod, at least three transmission rods are evenly distributed on the bottom of the bag pulling frame in the circumferential direction, stretching rings are arranged at the ends of the transmission rods, and pulling bags are detachably arranged between the stretching rings and the upper edge of the wall of the rotary drum. The shell assembly comprises a side shell and an upper cover hinged to the side shell, a feeding assembly is arranged on the upper cover, a vertically-arranged main spraying pipe is arranged on the upper cover, the main spraying pipe is connected with pure water or industrial water through an anti-explosion pressure pump through a pipeline, and a plurality of spraying openings are formed in the side wall, right opposite to the rotary drum, of the main spraying pipe from top to bottom.

Owner:JIANGSU HUADA CENTRIFUGE

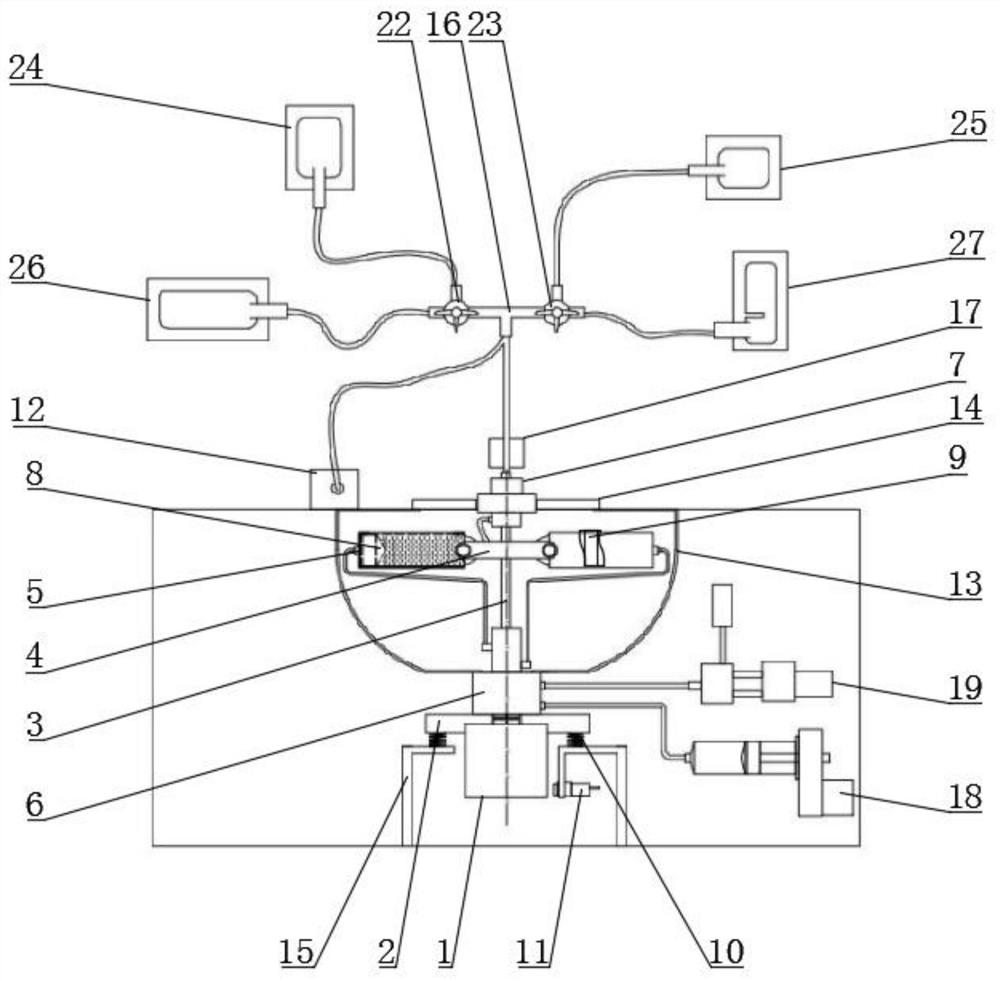

Blood component automatic balancing and separating apparatus and method

PendingCN112063507AImprove separation efficiencyImprove product qualityBioreactor/fermenter combinationsBiological substance pretreatmentsBlood componentControl engineering

The invention relates to the technical field of blood component treatment, and discloses blood component automatic balancing and separating apparatus. The apparatus comprises a double-channel rotary seal and a single-channel rotary seal, wherein the double-channel rotary seal communicates with a centrifugal tube, a double-acting air pump, a balancing tube and a mass controller, the mass controlleris electrically connected with a vibration sensor, the centrifugal tube is movably matched with a first piston, the balancing tube is movably matched with a second piston, and the single-channel rotary seal communicates with the centrifugal tube and a first three-way pipe. The invention further discloses a blood component automatic balancing and separating method. The method comprises the following steps: S1, bagging a blood sample; S2, feeding the blood sample into a tube; S3, performing centrifugal balancing; S4, performing centrifugation; S5, performing separation balancing; and S6, performing separating and bagging. According to the apparatus and method, different blood components are guided to the corresponding flow directions, the separation efficiency of the blood components and the product quality are improved, the mass distribution balance of a rotor is kept all the time through the vibration sensor and the mass controller, and thereby the centrifugal effect is guaranteed.

Owner:金西盟(天津)人工智能有限责任公司

Double-frequency-conversion high-speed centrifugal machine

PendingCN114798192AAchieve separationSimple speed regulationRotary centrifugesMagnetic separationElectric machineFrequency conversion

The invention provides a dual-frequency-conversion high-speed centrifugal machine, and relates to the technical field of dual-frequency-conversion high-speed centrifugal machines. A double-frequency-conversion high-speed centrifugal machine comprises a centrifugal machine frame, a threaded conveying shaft, a first frequency conversion motor and a second frequency conversion motor, a second centrifugal bin is arranged in the centrifugal machine frame, the threaded conveying shaft is located in the second centrifugal bin, and the threaded conveying shaft is rotationally connected with the centrifugal machine frame. One end of the threaded conveying shaft extends out of the centrifugal machine frame, one end of the threaded conveying shaft is in transmission connection with the first variable frequency motor, one end of the threaded conveying shaft is in transmission connection with the second variable frequency motor, the feeding port is communicated with the first centrifugal bin, the first centrifugal bin is communicated with the second centrifugal bin, and the second centrifugal bin is communicated with the second variable frequency motor. And a first magnet is arranged in the peripheral side wall of the threaded conveying shaft. The double-frequency-conversion high-speed centrifugal machine is simple in structure, the size is reduced, the centrifugal efficiency is improved, and meanwhile the separation process of iron particles is accelerated.

Owner:沧州市华油钻采机械设备有限公司

A portable blood centrifuge

A portable blood centrifuge disclosed by the present invention comprises a base, a top cover is provided on the upper side of the base, a centrifugal chamber is provided between the top cover and the upper end surface of the base, and a centrifugal chamber is rotated inside the centrifugal chamber. Rotating block, six test tube placement devices are evenly arranged on the outer periphery of the rotating block, and the test tube placement devices are used to place test tubes, and a power device is provided in the upper end surface of the base. The present invention adopts a portable design, which is small in size and easy to carry. At the same time, metal counterweights are used to share the weight, which makes the centrifugal rotation more uniform, effectively reduces the occurrence of vibration, and reduces the probability of downtime adjustment. At the same time, when centrifuging, the test tube is in a horizontal state, which can better promote blood stratification. At the end, the flow between the layers is reduced to ensure the centrifugal effect.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Micro centrifuge

The invention relates to the field of laboratory equipment, in particular to a micro centrifuge. The micro centrifuge includes a rotating shaft and a motor for driving the rotating shaft to rotate, wherein a turntable is fixedly connected with the rotating shaft; the turntable is fixedly connected with the middle of the rotating shaft; a rotating test tube is arranged on the turntable; the upper side and the lower side of the turntable are correspondingly provided with a first magnet and a second magnet that are connected with the rotating shaft in a thread mode; the first magnet and the second magnet move in opposite directions; reset members are connected with the first magnet and the second magnet; a first magnetic strip and a second magnetic strip are correspondingly arranged on the upper end and the lower end of the test tube; the first magnet and the first magnetic strip are attracted to each other; and the second magnet and the second magnetic strip repel each other. According to the micro centrifuge, it is convenient for medical staff to read the scale on the test tube, so that reading errors are reduced.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

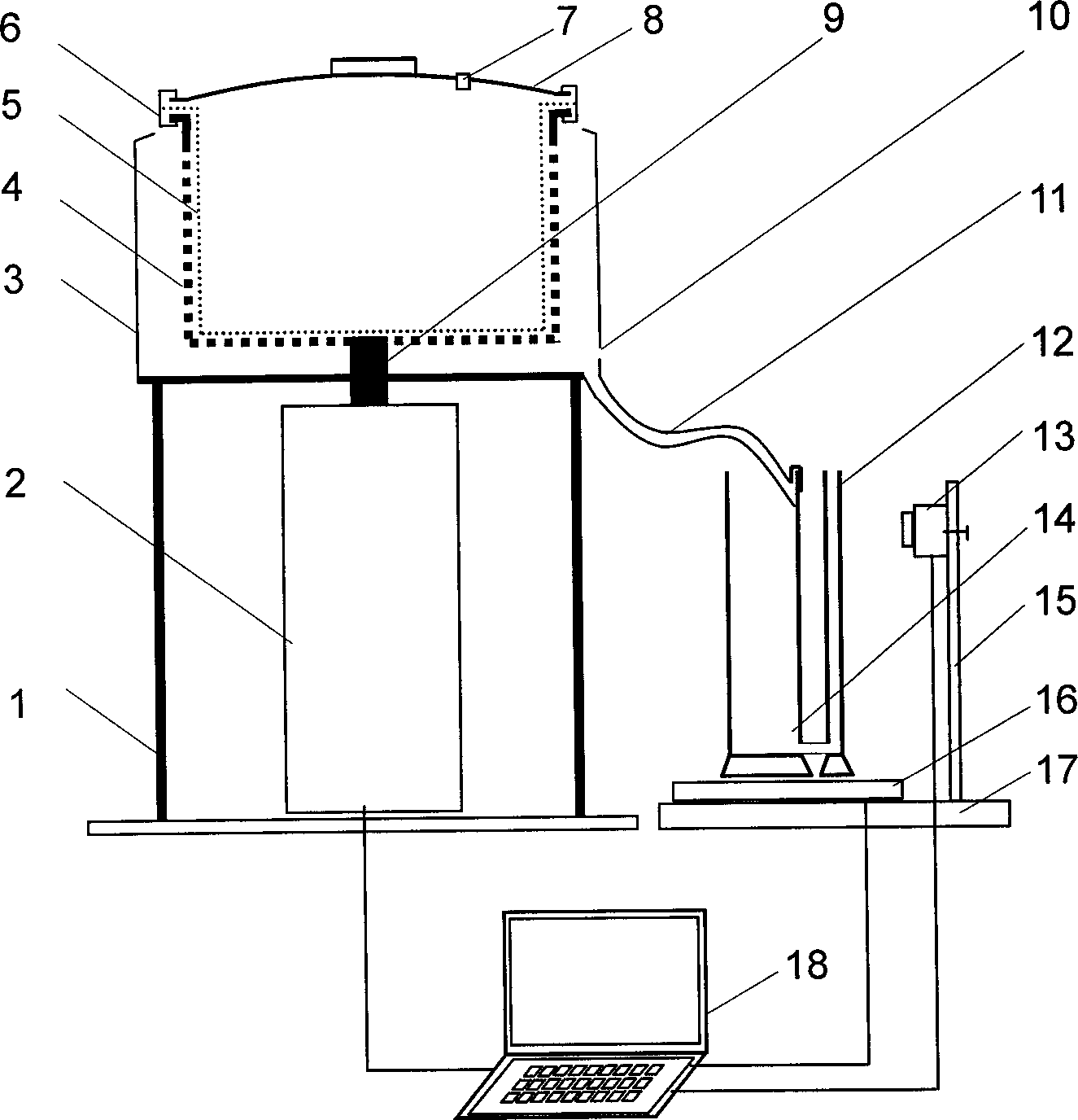

Testing device for measuring sludge dewatering characteristics

ActiveCN102980834BGuaranteed dehydration propertiesStable dehydration propertiesWeighing by removing componentGeotechnicsEngineering

The invention relates to a testing device for measuring sludge dewatering characteristics and belongs to the technical field of environmental geotechnics. The testing device consists of a bracket, a speed-regulating motor, a filtrate shield, a centrifuge cup, a filter bag, a sealing cap cover, a metering tube, a photographic device, a liquid accommodating device, a guide rail, a weighing device, a base and a computer. With the adoption of the centrifuge cup dewatering mode, the defects of the vacuum filtering air leakage and unstabitily of vacuum degree and the like are overcome. The speed-regulating motor is adjustable in rotating speed, and the testing device can measure the sludge dewatering characteristics under different separation factor actions. According to an air outlet on the filtrate shield, the hose is tightly adhered to an inner wall of the liquid accommodating device, stable filtrate in the liquid accommodating device is guaranteed, and the precision of the reading of the photographic device is ensured. The testing parameters are set on a computer, the data is automatically processed through a computer program, and the testing efficiency is greatly improved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

An integrated device for pre-treatment of groundwater volatile organic compounds

InactiveCN104697834BAvoid multiple transfersAvoid introducingPreparing sample for investigationTesting waterSorbentDesorption

The invention relates to an integrated device for the pretreatment of groundwater volatile organic compounds, which comprises a four-way pipe assembled on a cylindrical container, a sealing cover is screwed into the container port, a tube body is screwed into the sealing cover, the lower part of the tube body shrinks radially, and the tube body The body is provided with slits, and a thin-walled tube is set in the tube body. The upper port of the thin-walled tube is radially expanded, and the expanded end is embedded in the expanded end formed by the radially expanded upper port of the tube body. The invention realizes the versatility of the adsorption / desorption batch experiment oscillation and the centrifuge tube body, can realize the sealed connection with the solid phase extraction device, avoids the steps of multiple transfer of the solution, open pipetting of the supernatant and the like in the traditional process, and can be used Reduce the loss of adsorbent and adsorbate, and effectively prevent the escape of volatile organic compounds. It can realize the integration of activation, enrichment, cleaning and elution processes, reduce errors and secondary pollution caused by manual complicated operations, and ensure the sealing of the whole process. It can achieve fixed volume extraction, and realize extraction sealing and batching.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

A kind of swirl plate column used for producing thiourea

ActiveCN106111026BImprove stabilityGuaranteed centrifugal effectOrganic chemistryLiquid-gas reaction processesThioureaNitrogen

Owner:河北日新化工有限公司

Centrifugal separator with wall scraping function

InactiveCN109013074AGuaranteed centrifugal effectImprove centrifugation efficiencyCentrifugesDrive shaftEngineering

The invention discloses a centrifugal separator with a wall scraping function. The centrifugal separator with the wall scraping function comprises a machine body, a deodorization box is arranged inside the machine body, a disinfection box is arranged on one side of the deodorization box, and a separation cavity is formed in the top end of the deodorization box; the separation cavity is connected with the disinfection box through a pipeline, a rotating drum is arranged inside the separation cavity, and a transmission shaft is arranged at the bottom end of the rotating drum; a motor I is arranged on one side of the machine body, an output shaft of the motor I is connected with the transmission shaft through a belt, and a feeding port is formed in the top end of the rotating drum; and a wallscraping mechanism cooperating with the rotating drum is arranged at the top end of the inner wall of the separation cavity, an operation panel is arranged on one side of the machine body and locatedabove the motor I, and a plurality of discharging ports are formed in the bottom end of the rotating drum. The centrifugal separator with the wall scraping function has the beneficial effects that thepurpose of scraping the inner wall of the rotating drum is achieved, then the centrifugal effect of the centrifugal separator is ensured, and then the centrifugal efficiency of the centrifugal separator is improved.

Owner:HEFEI OUYU AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com