Liquid skimming device of scraper centrifugal machine

A technology of skimming device and centrifuge, which is applied in the direction of centrifuge, etc., can solve the problems of incomplete skimming and filter cake, and achieve the effects of preventing incomplete skimming, ensuring centrifugation effect, product quality and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

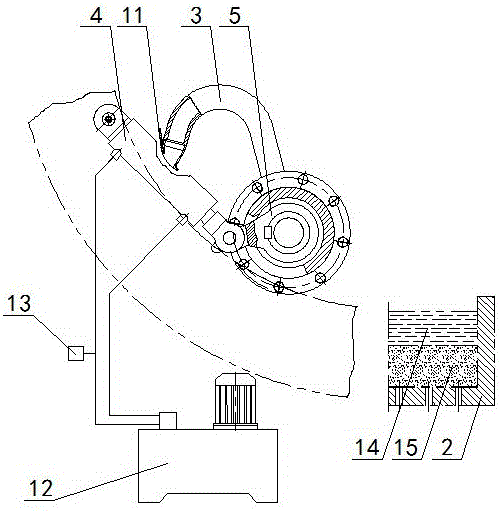

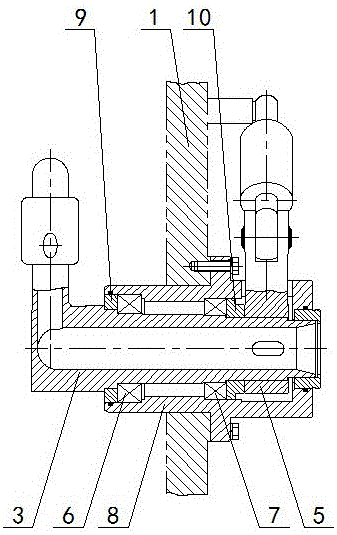

[0017] Embodiment 1: as figure 1 , 2 As shown, a scraper centrifuge skimming device includes a cover 1, a drum 2 is arranged in the cover 1, and a skimming pipe 3 passing through the cover 1 is arranged on the cover 1, the The middle part of the skimming tube 3 is movably connected with the machine cover 1, and a swing mechanism connected with the skimming tube 3 is provided at the liquid outlet end of the skimming tube 3, and the liquid inlet end of the skimming tube 3 is connected to the drum 2 Corresponding to the inner cavity.

[0018] Wherein, the liquid skimming pipe 3 includes a straight pipe section and an arc-shaped pipe section, the straight pipe section is movably connected with the machine cover 1, one end of the arc-shaped pipe section is vertically connected with the straight pipe section, and the liquid inlet of the arc-shaped pipe section The end corresponds to the inner cavity of the drum 2.

[0019] In the present invention, the swing mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com