Granulating device and heat recovery method for melted slag

A technology for melting slag and heat recovery, applied in the direction of recycling technology, etc., can solve the problems of large air volume and air pressure, difficult to meet energy saving and economical, and low temperature of recycled heat exchange air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

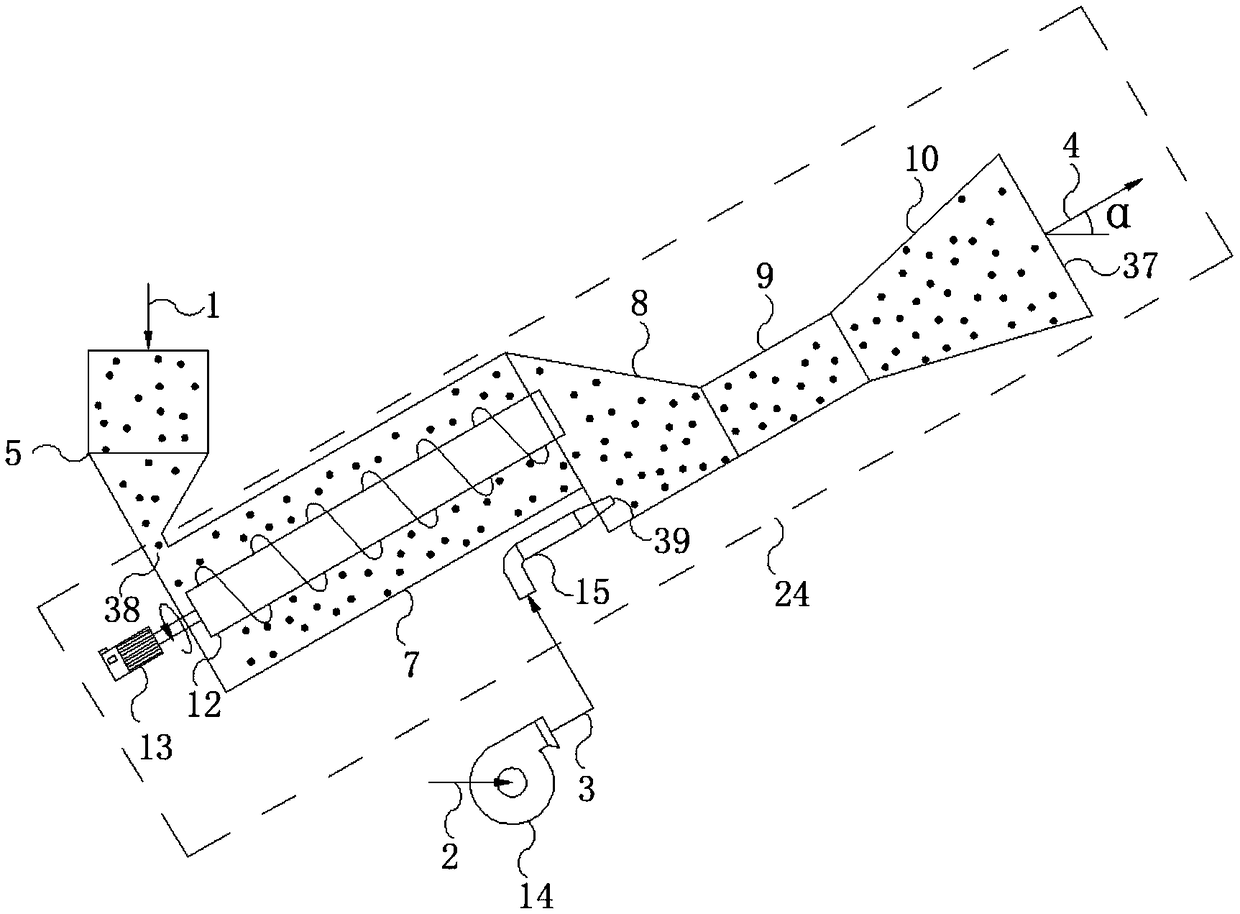

[0051] This embodiment is a molten slag granulation device and a heat recovery method, including three processes of gas powder flow generation, molten slag granulation, and powder return. The gas powder flow generation process is as follows figure 1 As shown, it is produced by a low-pressure screw pump air-transporting powder flow mixer, and the mixer is provided with a feeding section 7, an accelerating section 8, a mixing section 9, and an injection section 10. The mass ratio of powder to air is 70:1. After the powder 1 enters the powder inlet 38 from the hopper 5, the screw shaft 12 with blades is driven by the motor 13 to make the powder flow from the feeding section 7 continuously. Pressed to the acceleration section 8, the compressed air 3 generated by the airflow power provided by the high-pressure fan or blower 14 enters the acceleration section 8 of the gas-powder mixer from the gas inlet 39, and the gas-powder mixture completes powder acceleration and forms in the ac...

Embodiment 2

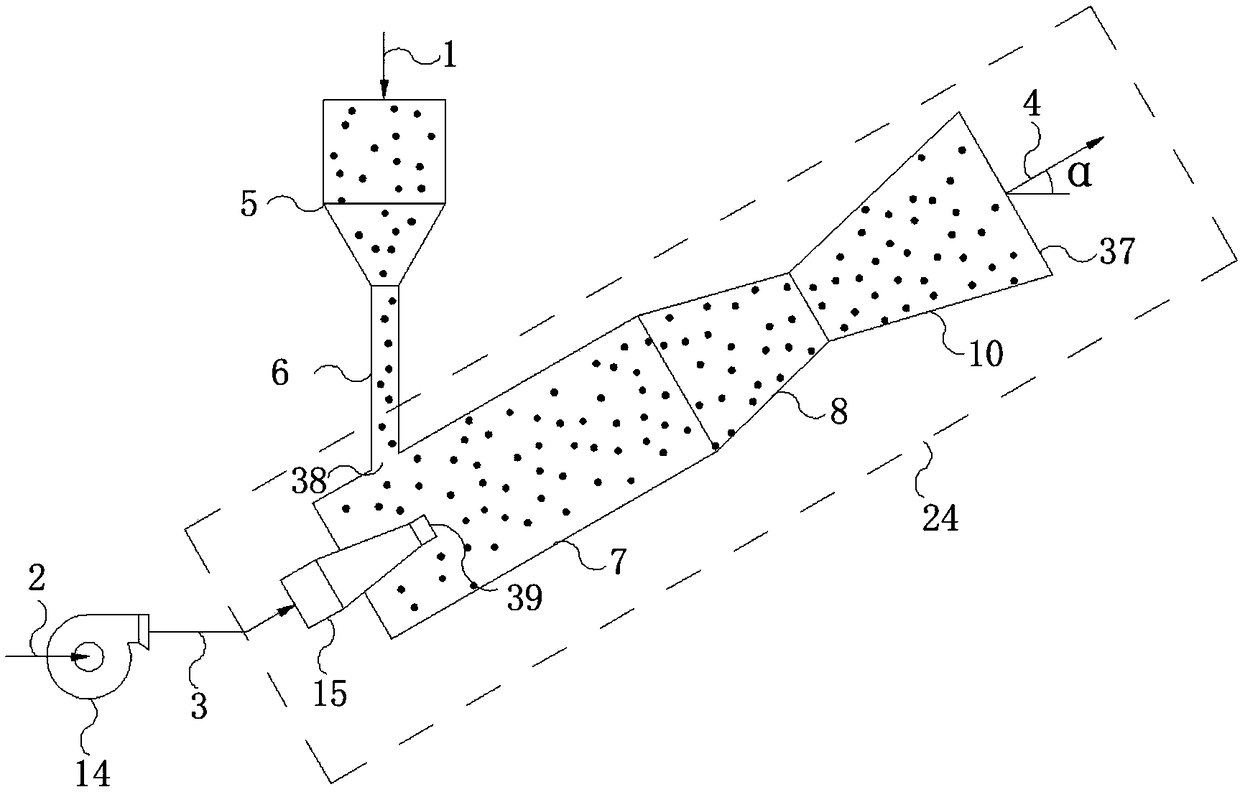

[0054] This embodiment is a molten slag granulation device and a heat recovery method, including three processes of gas powder flow generation, molten slag granulation, and powder return. The gas powder flow generation process is as follows figure 2 As shown, it is produced by a low-pressure gravity flow gas-conveying powder flow mixer, and a feeding section 7, an accelerating section 8, and an injection section 10 are arranged in the mixer. The mass ratio of powder to air is 90:1. The installation height of the powder feed hopper 5 is much higher than that of the air-powder mixer. The powder 1 falls into the air powder from the powder inlet 38 through the vertical feeding section 6 by its own gravity. The conveying section 7 of the mixer uses the compressed air 3 produced by the high-pressure fan or blower 13 as the working medium to enter the conveying section 7 from the gas inlet 39 to mix with the powder, and the air-powder flow mixture completes the powder acceleration i...

Embodiment 3

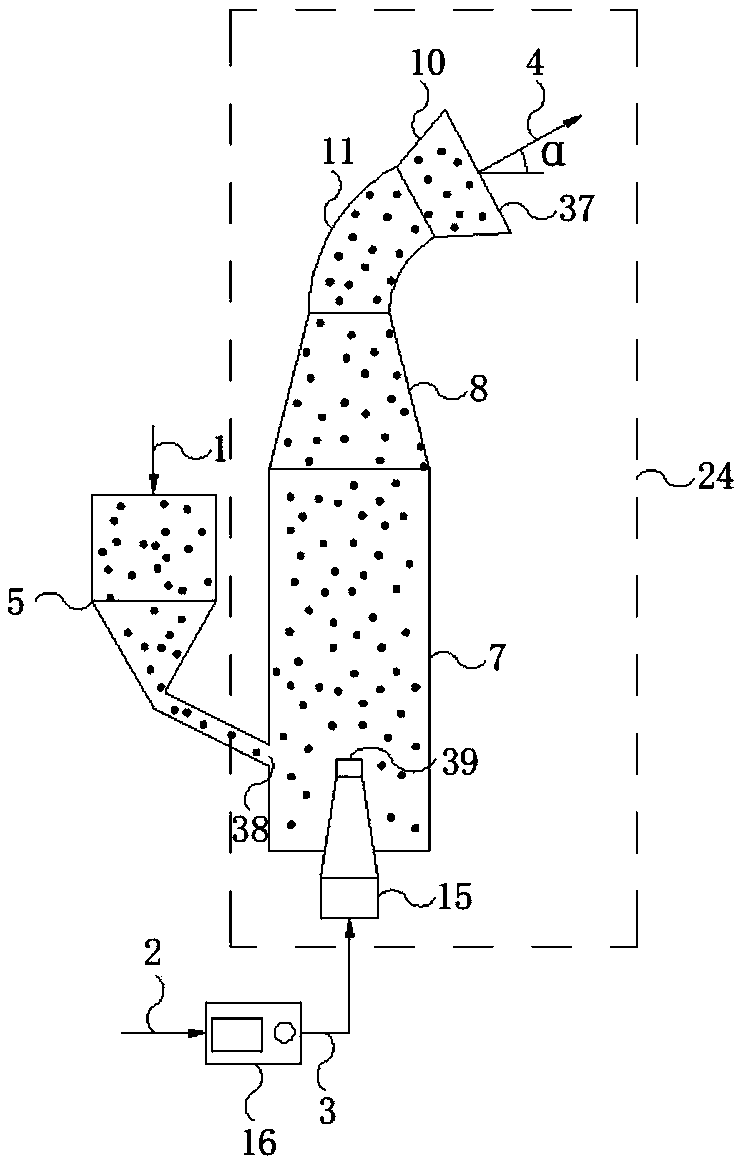

[0057] This embodiment is a molten slag granulation device and a heat recovery method, including three processes of gas powder flow generation, molten slag granulation, and powder return. The gas powder flow generation process is as follows image 3 As shown, it is produced by a high-pressure air compressor gas delivery powder mixer. The mixer is provided with a feeding section 7, a curved flow path 11, and an injection section 10. The arc of the curved pipeline is 60°. The mass ratio of powder to air is 110:1. The compressed air 3 produced by the air compressor 16 is used as the working medium to enter the delivery section 7 of the jet powder mixer from the gas inlet 39, and the hopper is fed by airflow suction. The powder in 5 is sucked into the air-powder mixer, and the air-powder flow mixture completes the powder acceleration in the acceleration section 8, and the large particle powder is sprayed out close to the outside of the elbow under the action of centrifugal force i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com