Centrifugal pump

A centrifugal pump and casing technology, applied in the field of machinery, can solve the problems of inconvenient cleaning, inconvenient and flexible installation of centrifugal pumps, weak centrifugal efficiency, etc., and achieve the effects of easy disassembly and cleaning, improving the scope of use, and avoiding large shocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve technical effects in the present application.

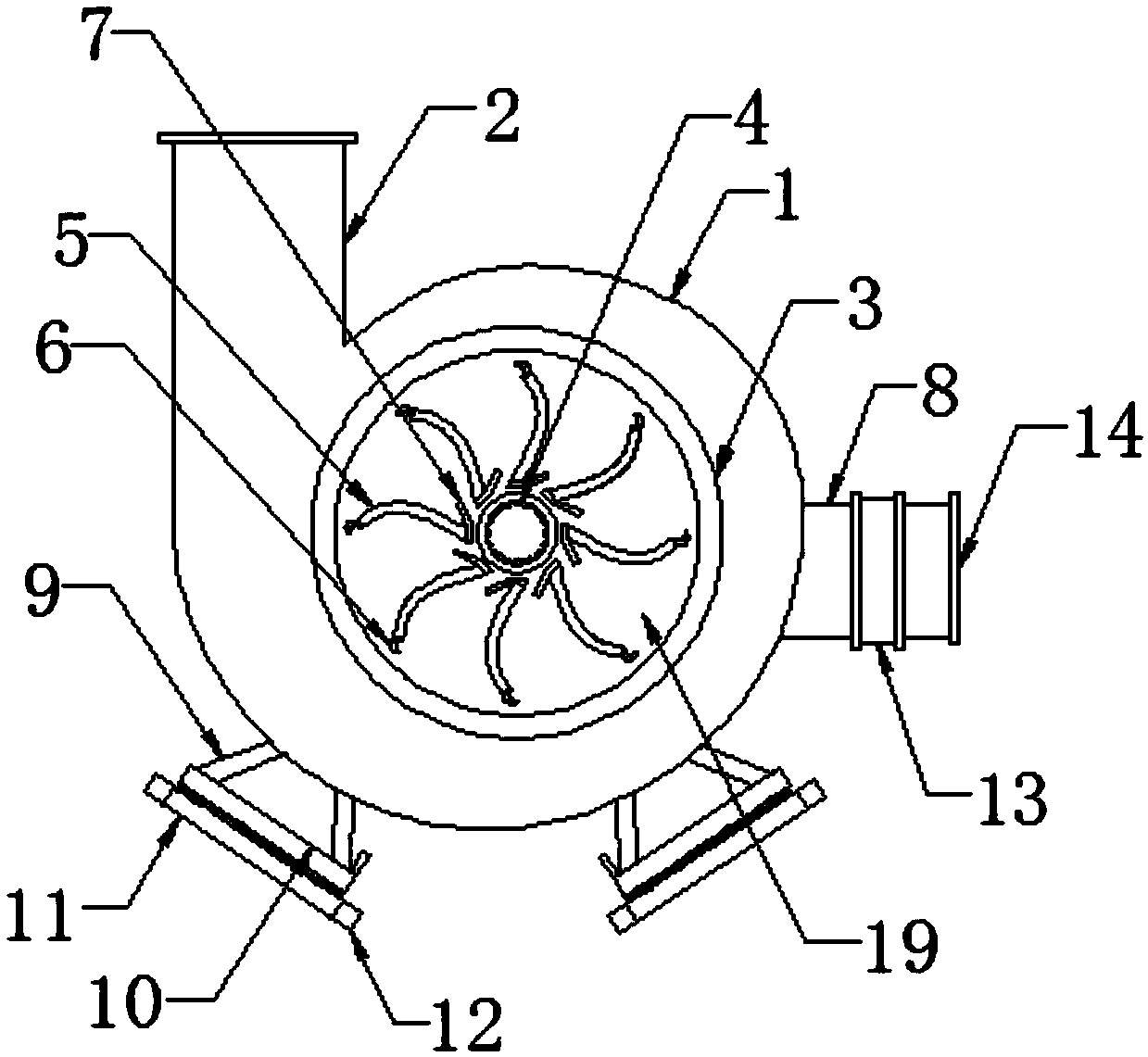

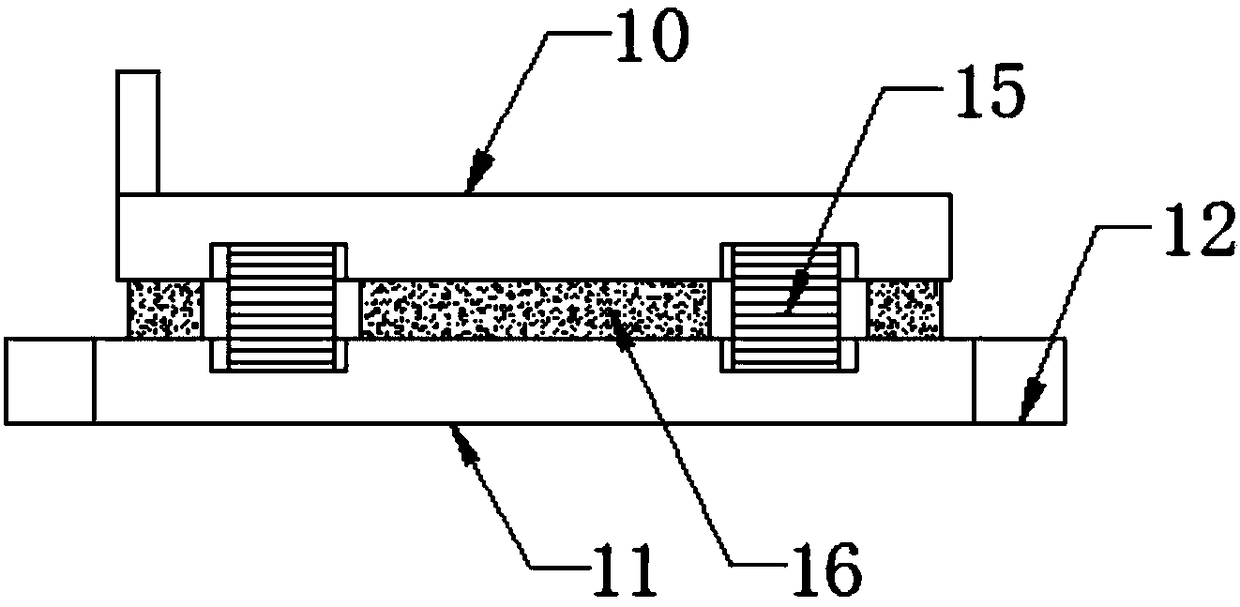

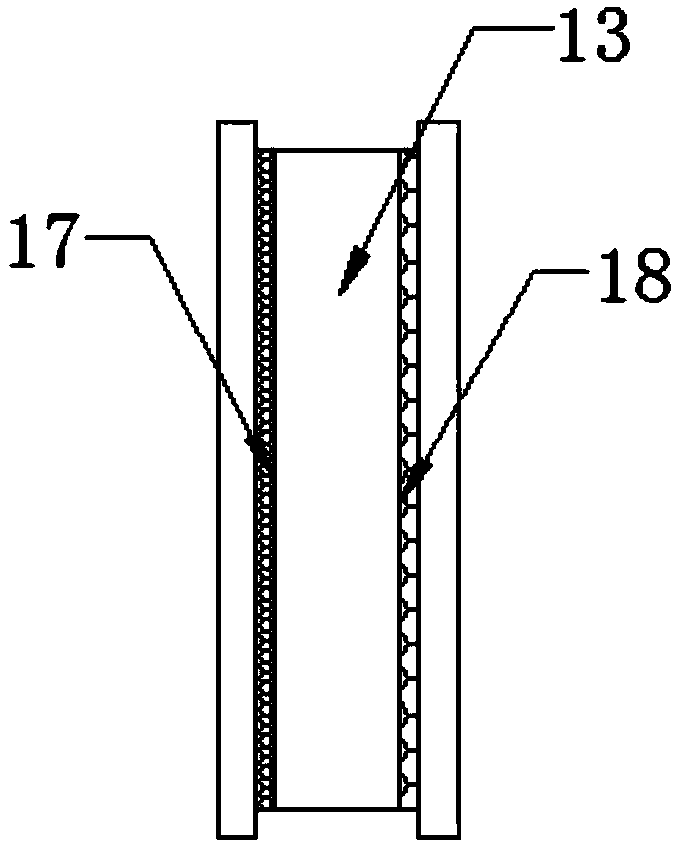

[0024] like Figure 1-4 As shown in the figure, a centrifugal pump of the present invention includes: a casing 1, a water outlet 2 and a cover plate 19, a water outlet 2 is provided on one side of the casing 1, a cover plate 19 is arranged inside the casing 1, and the cover plate 19 A connecting shaft sleeve 4 is arranged at the center of the cover plate 19, and several arc-shaped blades 5 are evenly arranged on both sides of the cover plate 19. Some two pairs of support rods 9 are connected with a shock-absorbing mounting seat mechanism, the other side of the housing 1 is provided with a water inlet 8, and one side of the water inlet 8 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com