Flat emery cloth wheel simulation grinding test machine

A technology of abrasive cloth wheel and testing machine, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of inconsistent test performance and actual use performance of 100-sheet sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

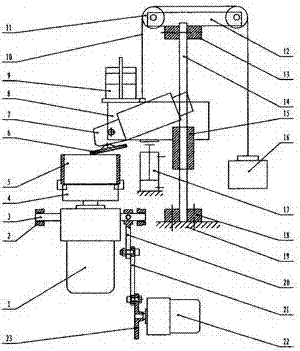

[0016] Such as figure 1 As shown, the crank swing mechanism is composed of an eccentric wheel 23, an adjustable connecting rod 21, a swing rod 20, etc., and is driven by a workpiece swing reduction motor 22 to drive the workpiece swing support shaft 3 to swing; the workpiece rotation reduction motor 1 is connected to the workpiece swing support shaft 3 , a workpiece chuck 4 is installed on the output shaft of the workpiece rotation deceleration motor 1, and a test workpiece 5 is mounted on the chuck. The workpiece swing support shaft 3 is connected with the swing rod 20, and the two ends of the workpiece swing support shaft 3 are installed in the workpiece swing support bearing 2, and the workpiece is tested. 5. The rotation is driven by the workpiece rotation deceleration motor 1; the steering, speed, start-stop time, etc. of the workpiece rotation deceleration motor 1 and the workpiece swing deceleration motor 22 are controlled by PLC menu, so that the 5 test workpiece can ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com