Heat radiating module and locking device thereof

A technology for locking devices and heat sinks, which is applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., and can solve problems such as inability to dissipate heat well and poor contact of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

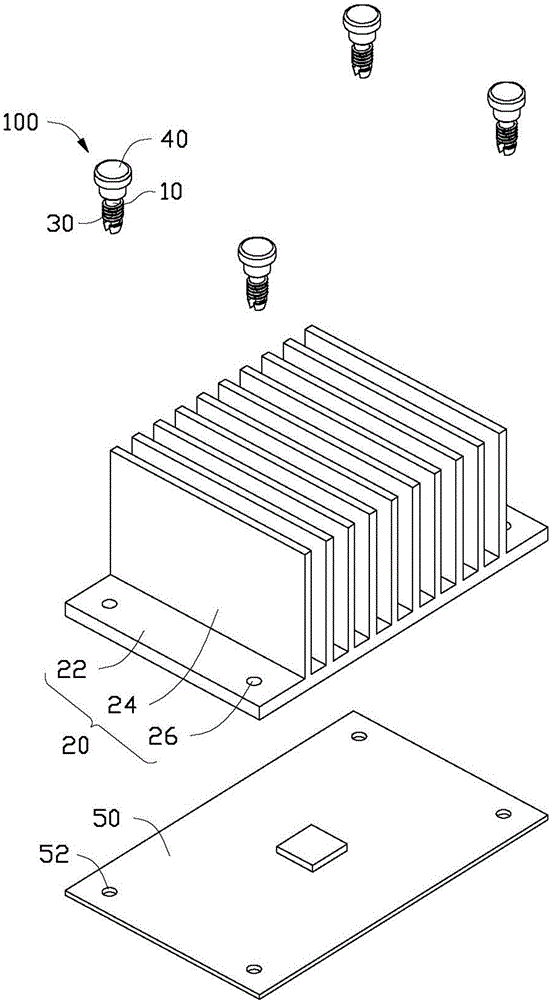

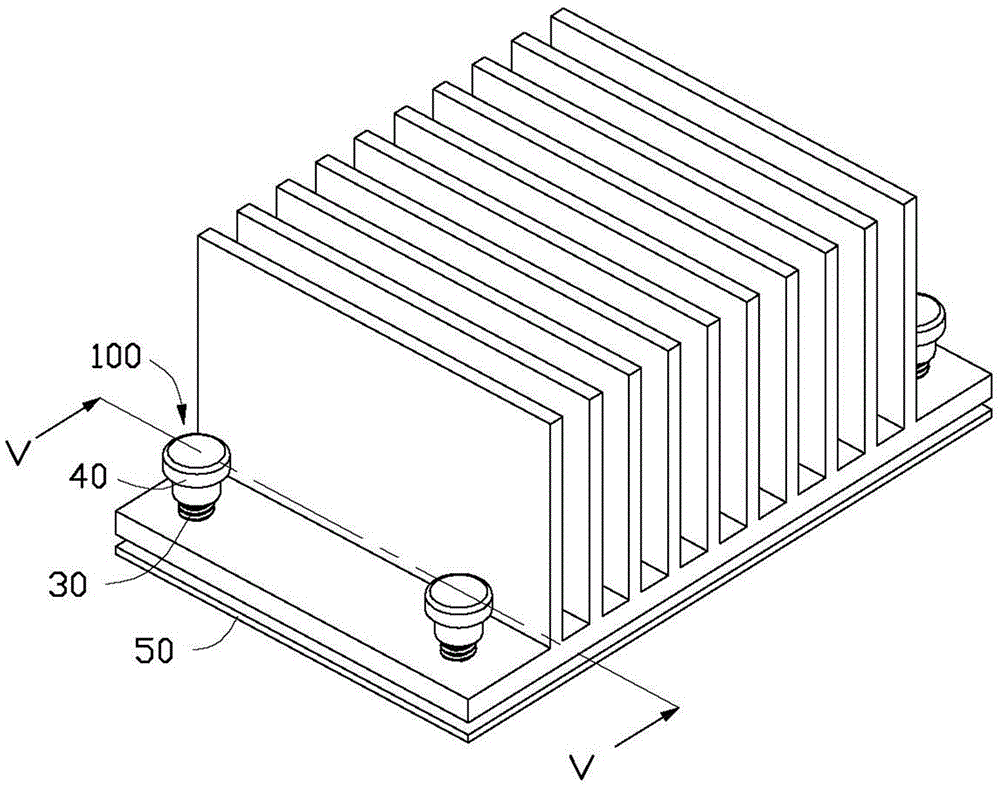

[0015] Please refer to figure 1 , The preferred embodiment of the heat dissipation module of the present invention includes a heat sink 20 , a main board 50 and a plurality of locking devices 100 .

[0016] The heat sink 20 includes a bottom plate 22 and a plurality of fins 24 extending upward from the bottom plate 22 . Four corners of the bottom plate 22 respectively define a through hole 26 .

[0017] The motherboard 50 defines a plurality of fixing holes 52 corresponding to the through holes 26 of the heat sink 20 .

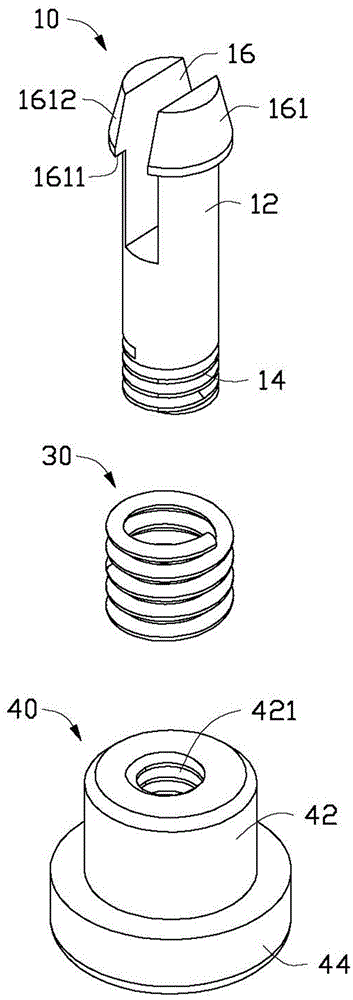

[0018] Please also refer to figure 2 , each locking device 100 includes a buckle bar 10 , an elastic element 30 and a nut 40 set on the buckle bar 10 .

[0019] The clasp 10 includes a cylinder 12 , a threaded portion 14 formed at one end of the cylinder 12 , and a locking portion 16 extending from the other end of the cylinder 12 . The locking portion 16 includes two spaced blocking hooks 161 . Each blocking hook 161 includes a blocking surface 1611 fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com