Combined socket

A combined, socket technology, used in coupling devices, two-part connection devices, electrical components, etc., can solve problems such as unavailability of power jacks, waste, etc., to improve use efficiency, reduce waste, and reduce work and living costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

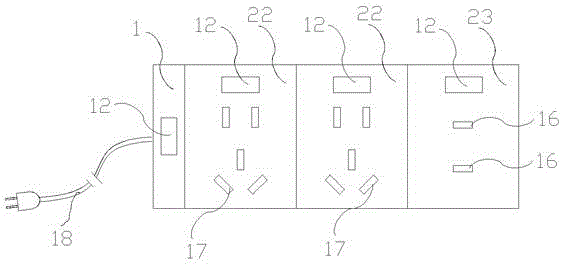

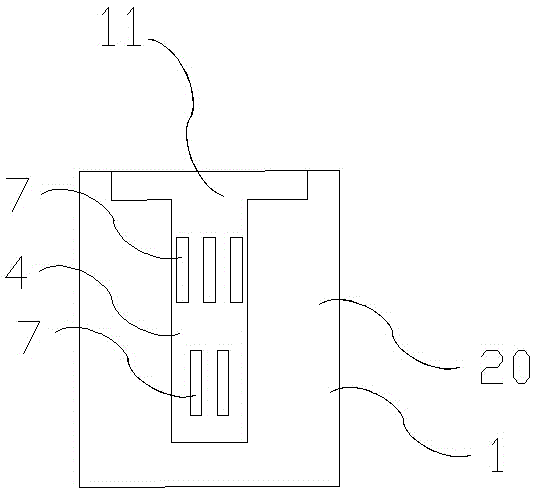

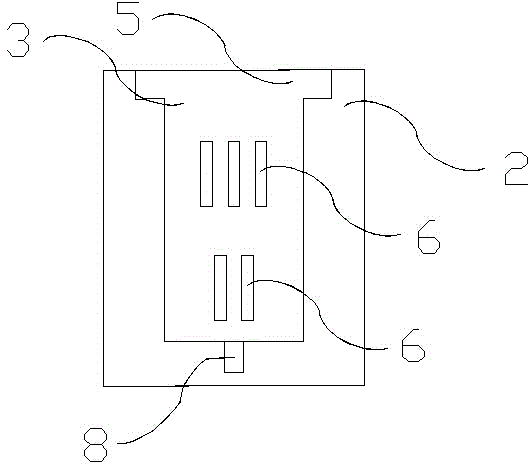

[0039] as attached Figure 1-19 As shown, a combined socket includes a basic part 1 and an extended part 2 connected together by a buckle. The connection structure between the basic part 1 and the extended part 2 is: the end of the extended part 2 is provided with a convex The out-type snap connection part 3, the protruding snap connection part 3 is provided with a protruding slide bar 5 and a protruding power supply connection antenna 6, and the end of the basic part 1 is provided with a recessed snap connection part 4, The recessed buckle connection part 4 is provided with a recessed slideway 11 and a recessed power output interface 7, the protruding power connection tentacles 6 are matched with the recessed power output interface 7, and the protruding slide bar 5 is matched with the recessed slide The protruding power connection antenna 6 is connected to the power socket 17 of the extension part 2, and the recessed power output interface 7 is connected to the power supply w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com