A reactor internally provided with a quartz tube

A quartz tube and reactor technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of difficult cleaning of the reactor, adsorption of impurities, etc., and achieve convenient removal and easy cleaning. , to avoid the effect of adsorbing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

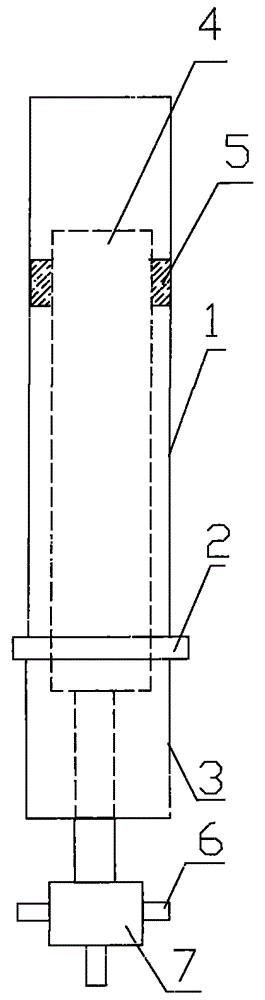

[0011] see figure 1 As shown, the figure shows the structure of a reactor with a built-in quartz tube provided by an embodiment of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0012] see figure 1 , a reactor with a built-in quartz tube, including an outer casing 1 and a tube holder 3 connected to the outer casing 1 through a clamp 2, the bottom of the tube holder 3 is integrally connected to a tube holder 3 A three-way valve joint 7, the outer casing 1 is provided with a quartz tray 5 and a quartz tube 4, and the bottom end of the quartz tube 4 is embedded in the tube holder 3.

[0013] The bottom end of the outer casing 1 has an outer edge, and the upper end of the tube holder 3 has a consistent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com