A multi-cylinder cone crusher frame

A cone crusher and frame technology, which is applied in the field of mining equipment, can solve the problems of inability to adjust the axial height of the fixed cone, high maintenance costs of large hydraulic lifting mechanisms, and low accuracy of crushing cavity size control, so as to achieve accurate crushing cavity size , adjust the size of the crushing cavity, and simplify the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

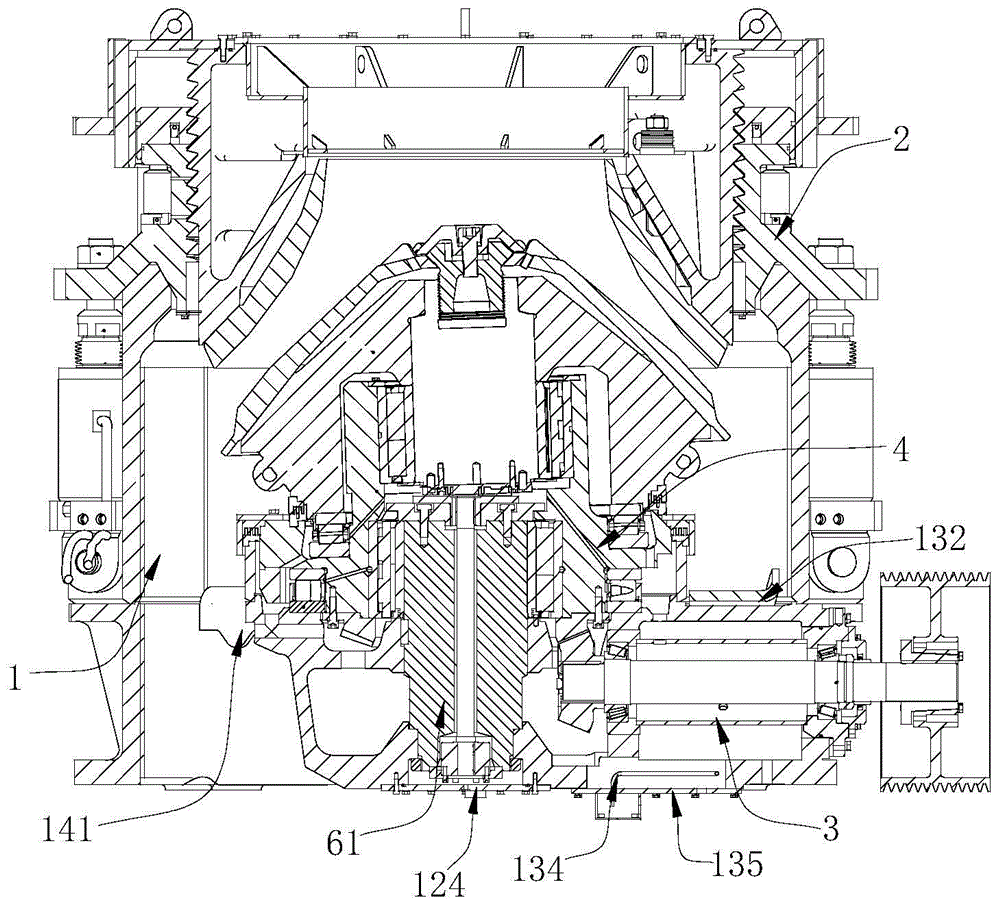

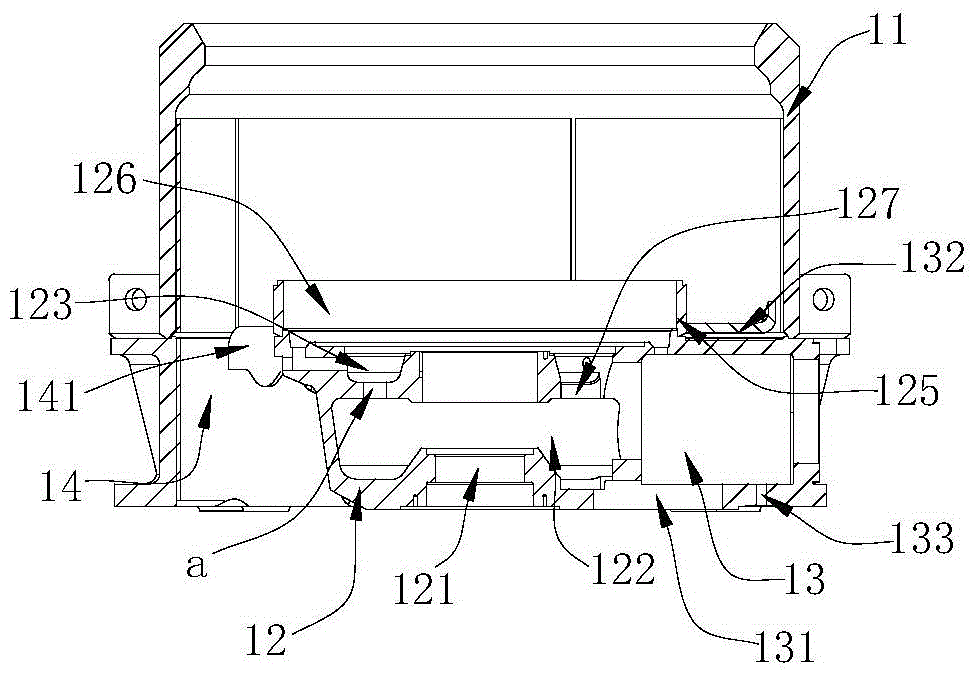

[0027] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

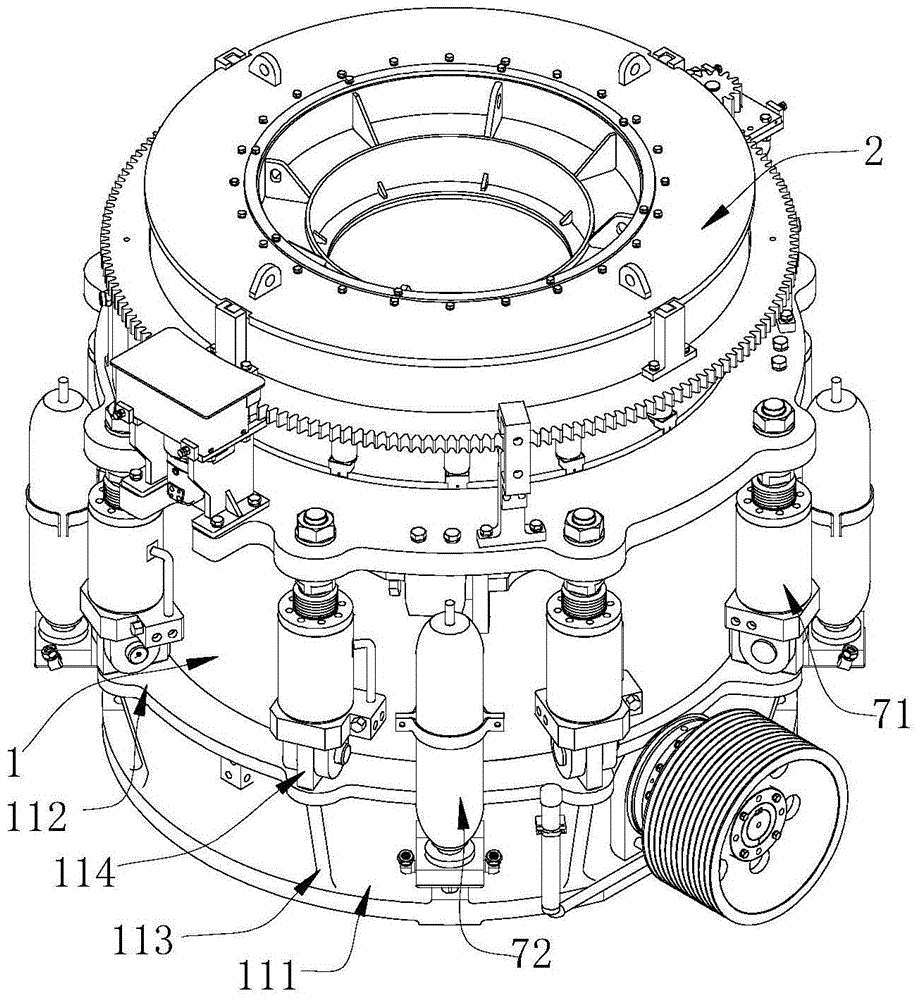

[0028] like Figure 1~Figure 8 The frame of a multi-cylinder cone crusher shown includes a lower frame 1 and an upper frame 2 .

[0029] The following content describes each part of the cone crusher in detail:

[0030] lower rack

[0031] The lower frame is composed of a lower frame outer cylinder 11, a lower frame inner cylinder 12 arranged at the center of the lower frame outer cylinder 11, and a root connecting the lower frame inner cylinder 12 and the lower frame outer cylinder 11. The transmission pipe 13 is integrally connected with a plurality of frame ribs 14 . The cross-section of the upper end port side wall of the lower frame outer cylinder 11 is V-shaped with the opening facing downward, and the bottom of the outer wall surface of the lower frame outer cylinder 11 protrudes outwards to be provided with an outer cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com