a steering gear

A steering gear and rack technology, applied in steering gears, mechanical steering gears, steering mechanisms, etc., can solve the problems of high noise, accelerated wear of rack bushings, affecting the comfort level of vehicles, and achieve good structural performance and modification. Small, strong usability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

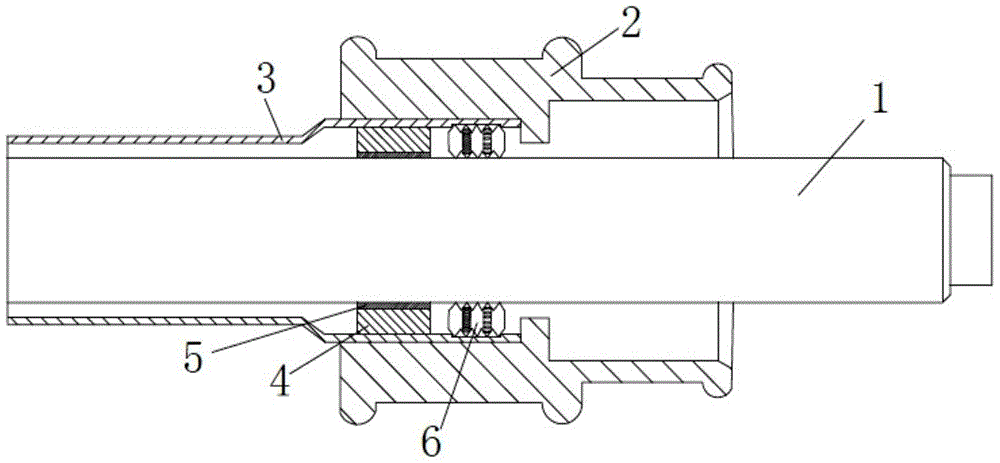

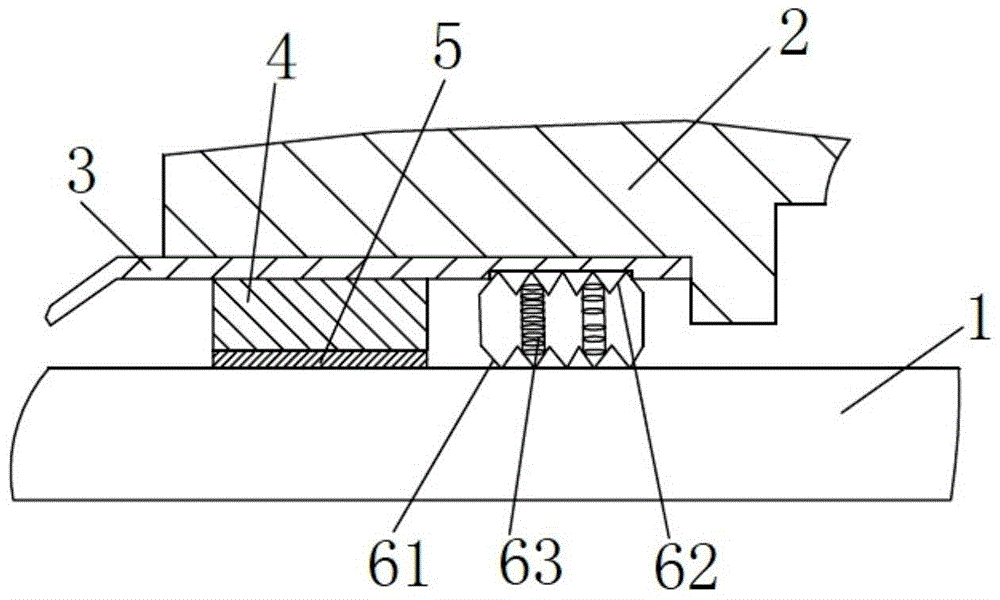

[0020] Steering gear of the present invention, as figure 1 As shown, it includes the steering gear housing and the rack 1 arranged in the housing, the housing includes the outer shell 2 and the inner lining 3, the rack bushing 4 is arranged between the rack 1 and the inner lining 3, and the rack 1 Driven by the gear, it can move in the rack bushing 4 along a straight line. Between the rack 1 and the inner liner 3 there is also an elastic bush 6 which can play a buffering role. The elastic bush 6 is a double-layer annular bush composed of an inner elastic sheet 61 and an outer elastic sheet 62 . The elastic bushing with double-layer structure has good structural performance, which can support and relieve the force well, so as to enhance the durability and practicality of the steering gear.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com